Device for preventing coke oven gas main pipe from forming negative pressure and using method thereof

A coke oven gas and anti-negative pressure technology, which is used in furnace safety devices, coke ovens, petroleum industries, etc., can solve the problem of failure to implement heating preventive control measures, negative pressure tempering explosion of heating pipes, and safe operation hazards of coke ovens, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

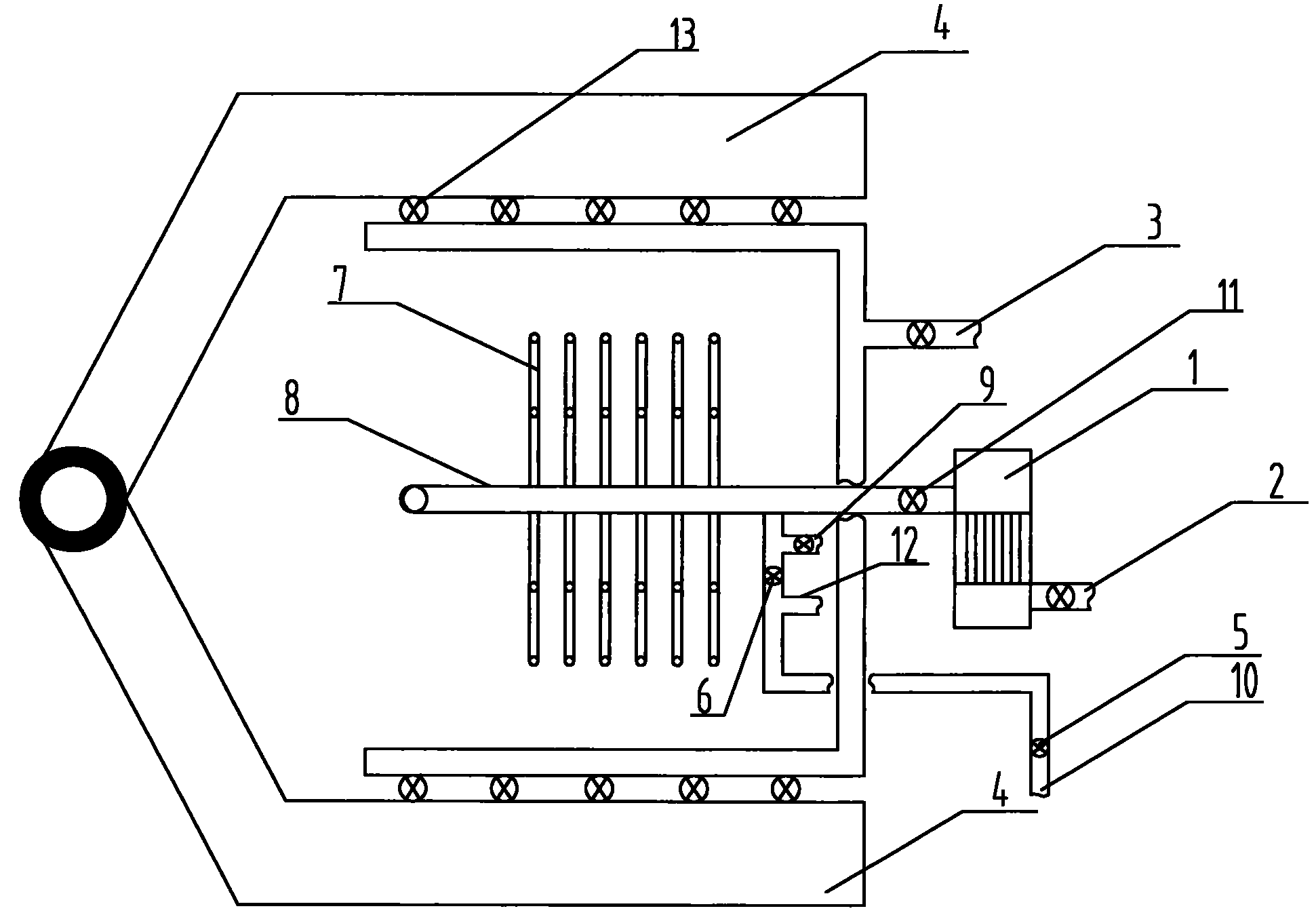

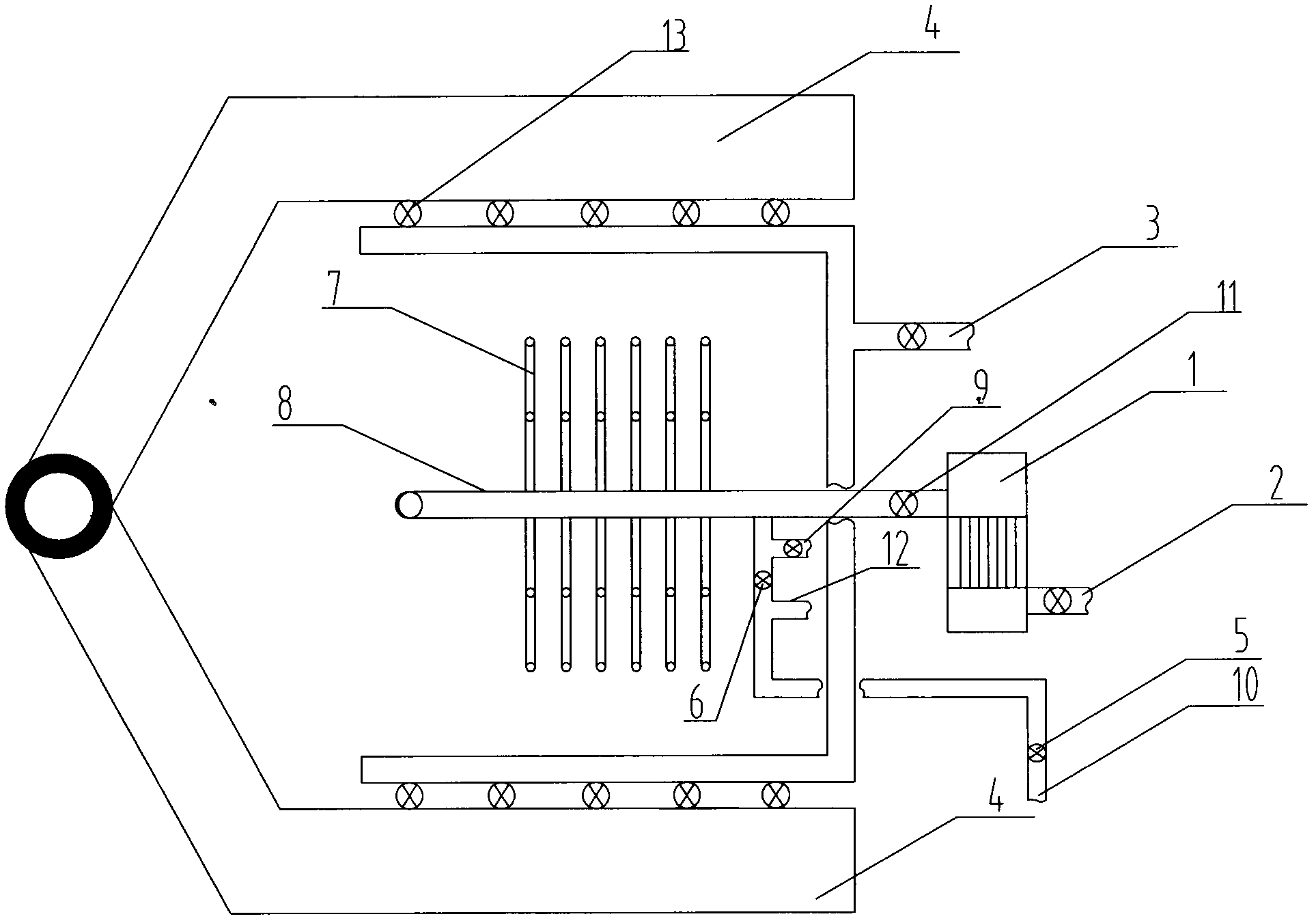

[0016] As shown in FIG. 1 , the device for preventing negative pressure from being formed in the coke oven gas main pipe includes a coke oven gas main pipe 8 connected with a negative pressure-preventing nitrogen pressure maintaining device. The anti-negative pressure nitrogen pressure maintaining device includes a nitrogen pipeline 10, the nitrogen pipeline 10 communicates with the coke oven gas main pipe 8, and the nitrogen pipeline 10 at the junction of the two is provided with a gas control valve 6, and the nitrogen pipeline 10 is also respectively A nitrogen control valve 5, a nitrogen pipeline cleaning valve 9 and a gas pressure measuring port 12 are provided.

[0017] The coke oven gas main pipe 8 is provided with a main gas valve 11 , and the coke oven gas main pipe 8 is connected with the coke oven gas pipeline 2 through the preheater 1 . The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com