Method for removing impurity bismuth in metal gallium

A technology for gallium metal and impurities, which is applied in the field of removing bismuth impurities in gallium metal by using a partial crystallization purification process, which can solve the problems of difficult high-purity gallium and unsatisfactory removal of bismuth impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] Example 1: A method for removing impurity bismuth in gallium metal, using a longitudinal temperature gradient solidification purification process to perform four times plus one partial crystallization operation, the process conditions for partial crystallization are: longitudinal temperature gradient 1.1~1.4°C / cm, average crystallization The speed is 3.2~4.2g / min, and the solid-liquid ratio is 75~85%.

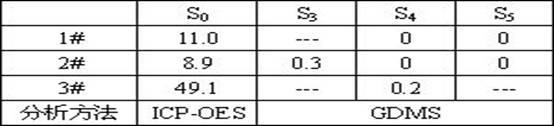

[0010] Using the above process conditions, 5 partial crystallization operations were performed on each of the 3 groups of samples, and the purification effect is shown in Table 1. where S 0 is the raw gallium, S 3 is the solid phase produced by the third partial crystallization, S 4 is the solid phase produced by the 4th partial crystallization, S 5 This is the solid phase produced by the 5th partial crystallization.

[0011] Table 1. Content of impurity bismuth elements Unit: ppm.wt.

[0012]

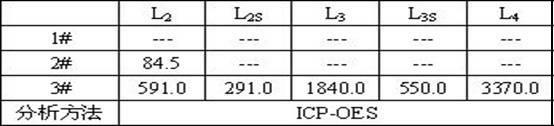

[0013] For the enrichment of impurity bismuth element, see Table 2. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com