Top-filled high-end-wall pillarless sublevel caving method extraction technique

A segmented caving method without pillars, which is applied in ground mining, earthwork drilling, underground mining, etc. It can solve the problems of overburden rock bonding, easy to increase bonding, and affect fluidity, etc., and achieve economic benefits Obvious, popular, and effective in preventing surface subsidence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

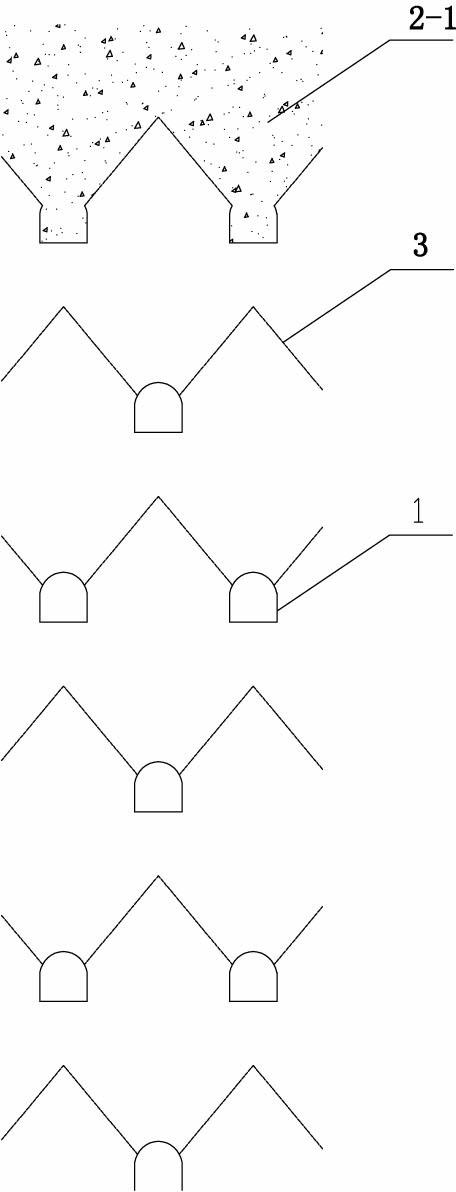

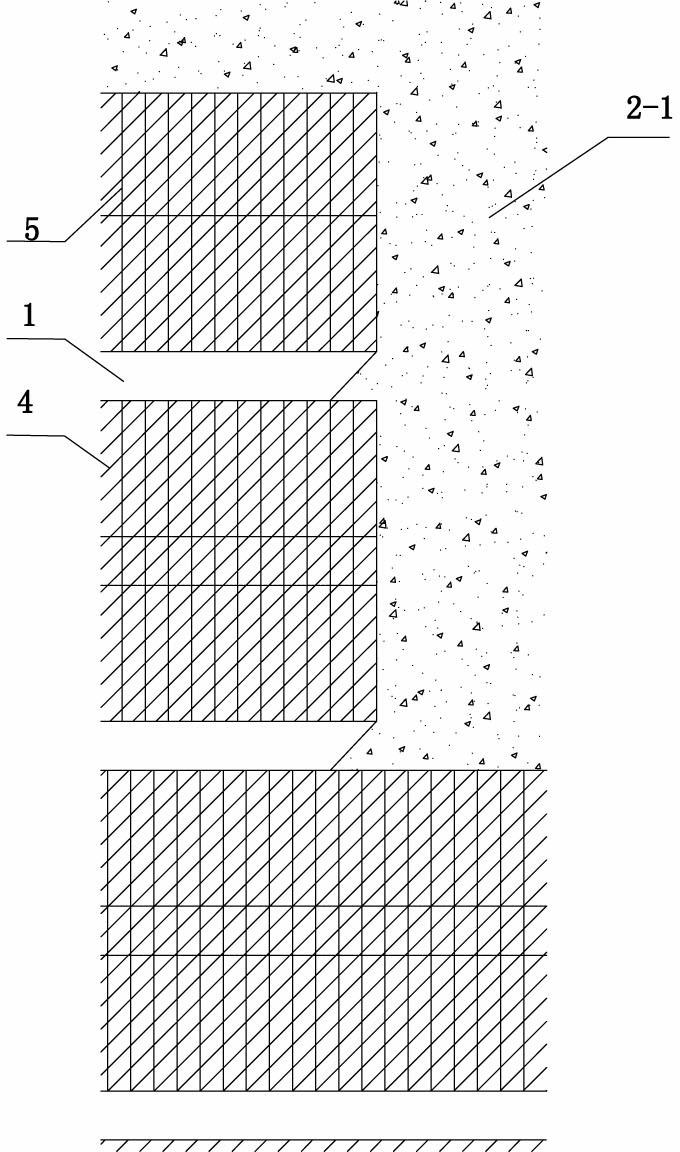

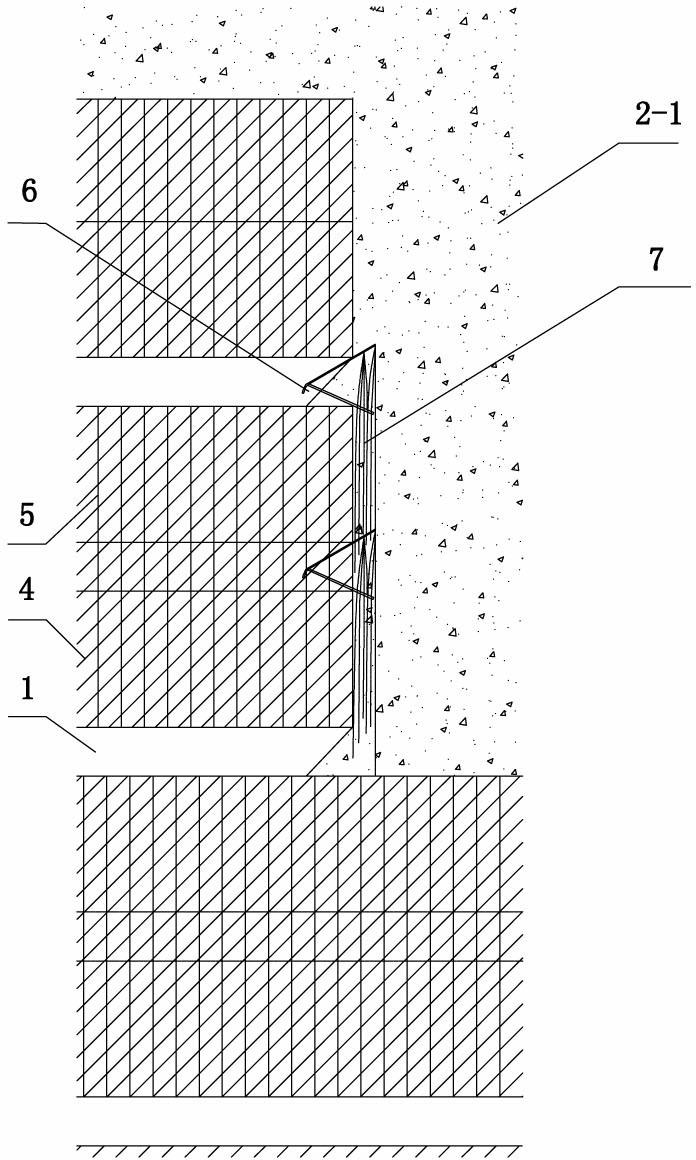

[0036] Such as Figure 1~7 As shown, a top-filled high-end wall without bottom pillar segmented caving mining process of the present invention includes dividing the ore body into stages, and arranging the mining approach 1 in a diamond-shaped staggered manner in the stages, and dividing the stages into segments , rock drilling, blasting and mining are all completed in mining roadway 1, figure 1 2-1 is the overburden rock, 3 is the ore body caving range line of each approach, and the upward fan-shaped medium-deep hole 5 is arranged in the mining roadway 1 by means of pre-concentrated rock drilling, and the retreat is carried out under the overburden rock layer 2-1 Type mining, two or more sections are taken as a group so that the end walls are upright at the same vertical position, that is, the high-end wall, figure 2 The middle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com