A method for forming double stress layer silicon nitride film

A technology of silicon nitride film and silicon nitride, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems such as the influence of N/PMOS electric mobility, and improve device performance, increase electric mobility, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to better understand the technical content of the present invention, specific embodiments are given together with the attached drawings for description as follows.

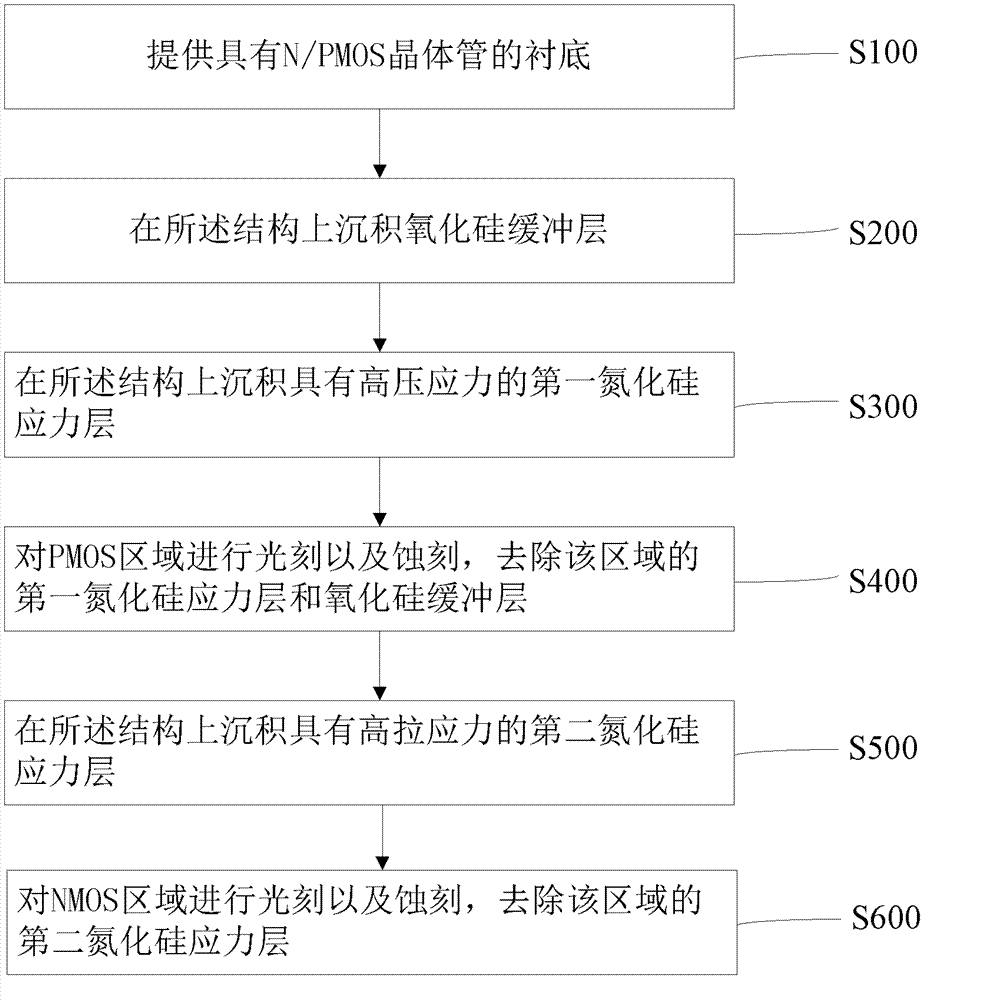

[0024] Please refer to figure 1 , figure 1 Shown is a flow chart of a method for forming a double stress layer silicon nitride film according to a preferred embodiment of the present invention. The present invention proposes a method for forming a double stress layer silicon nitride film, said method comprising the following steps:

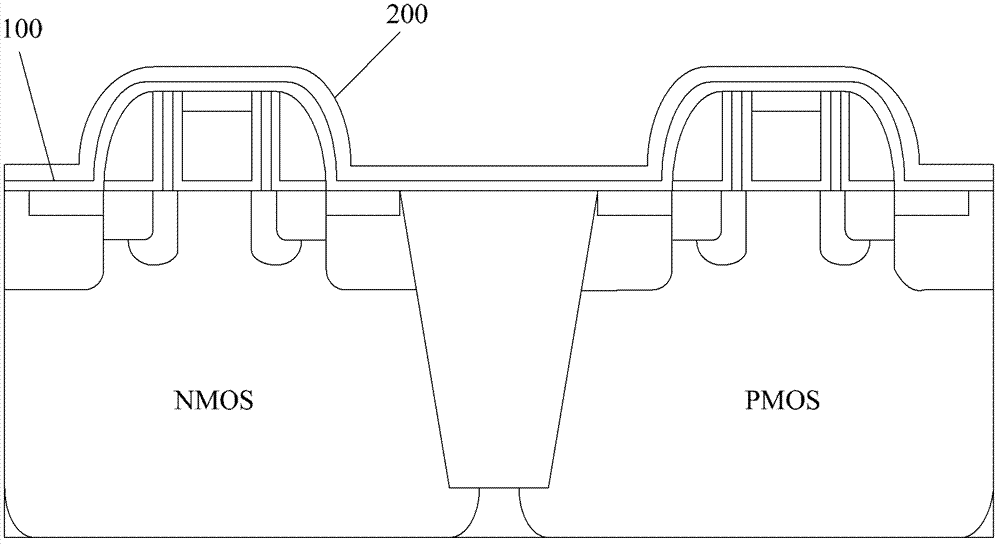

[0025] Step S100: providing a substrate with N / PMOS transistors;

[0026] Step S200: depositing a silicon oxide buffer layer on the structure;

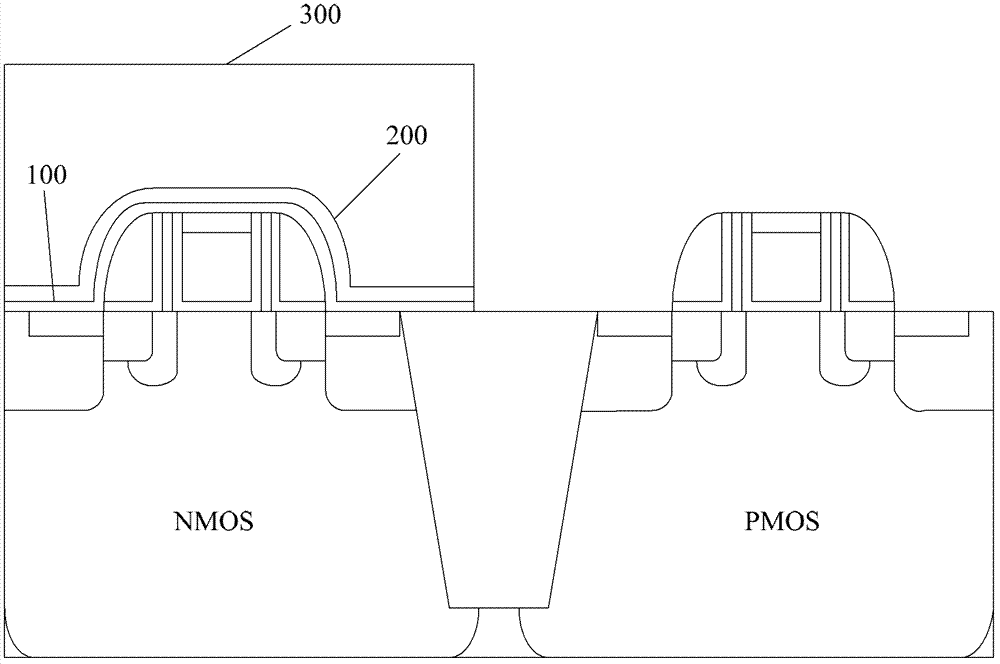

[0027] Step S300: Depositing a first silicon nitride stress layer with high voltage stress on the structure;

[0028] Step S400: performing photolithography and etching on the PMOS region, and removing the first silicon nitride stress layer and silicon oxide buffer layer in this region;

[0029] Step S500: Depositing a se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com