Bipolar battery made from thin film composite material and bipolar plate base of bipolar battery

A thin-film composite material and bipolar battery technology, which is applied to batteries with bipolar electrodes, lead-acid batteries, electrode carriers/collectors, etc., can solve problems such as bipolar plate corrosion, power loss, and low performance, and meet the requirements of Large-scale manufacturing, overcoming technical defects, and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

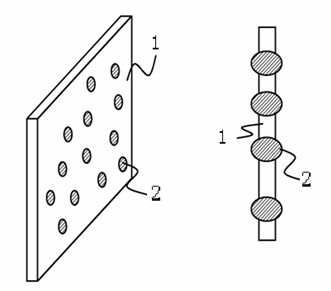

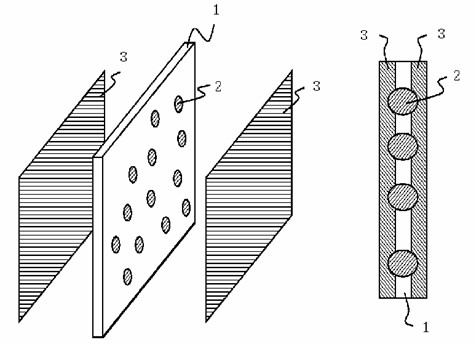

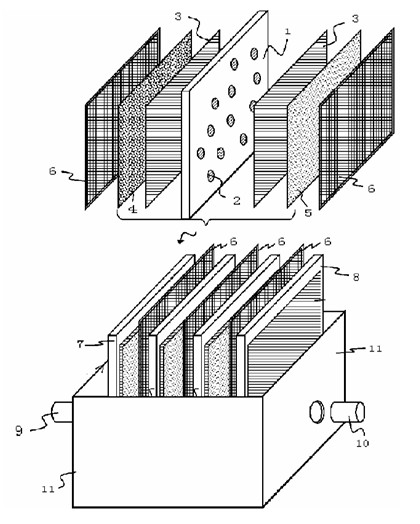

[0032] figure 1 It is a schematic diagram of the lattice structure of the bipolar battery substrate of the present invention. In the figure, a matrix 1 is included, and conductive particles 2 are placed in the matrix 1. The matrix 1 is made of thermosetting or thermoplastic polymer, and the conductive particles 2 are placed in the substrate. The substrate 1 is distributed in a lattice form and provided with one or more conductive particles 2 . The diameter of the conductive particles 2 is slightly thicker than the thickness of the substrate 1 and protrudes from the upper and lower surfaces of the substrate 1 .

[0033] The composite substrate of the bipolar battery is composed of a matrix 1 and conductive particles 2 made of acid-resistant thermosetting or thermoplastic polymers. like figure 1 As shown, the conductive particles 2 are evenly distributed on the plastic substrate in the form of a lattice according to the actual and design requirements. The lattice can be distrib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com