Waveguide-micro-strip integrated power distributor-synthesizer

A technology of success rate and distributor, which is applied to waveguide-type devices, electrical components, connecting devices, etc., can solve the problems of inability to be used in the field of solid-state power synthesis technology, inability to install solid-state devices, and insignificant effects, and achieve easy processing and realization. , compact structure, good phase consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

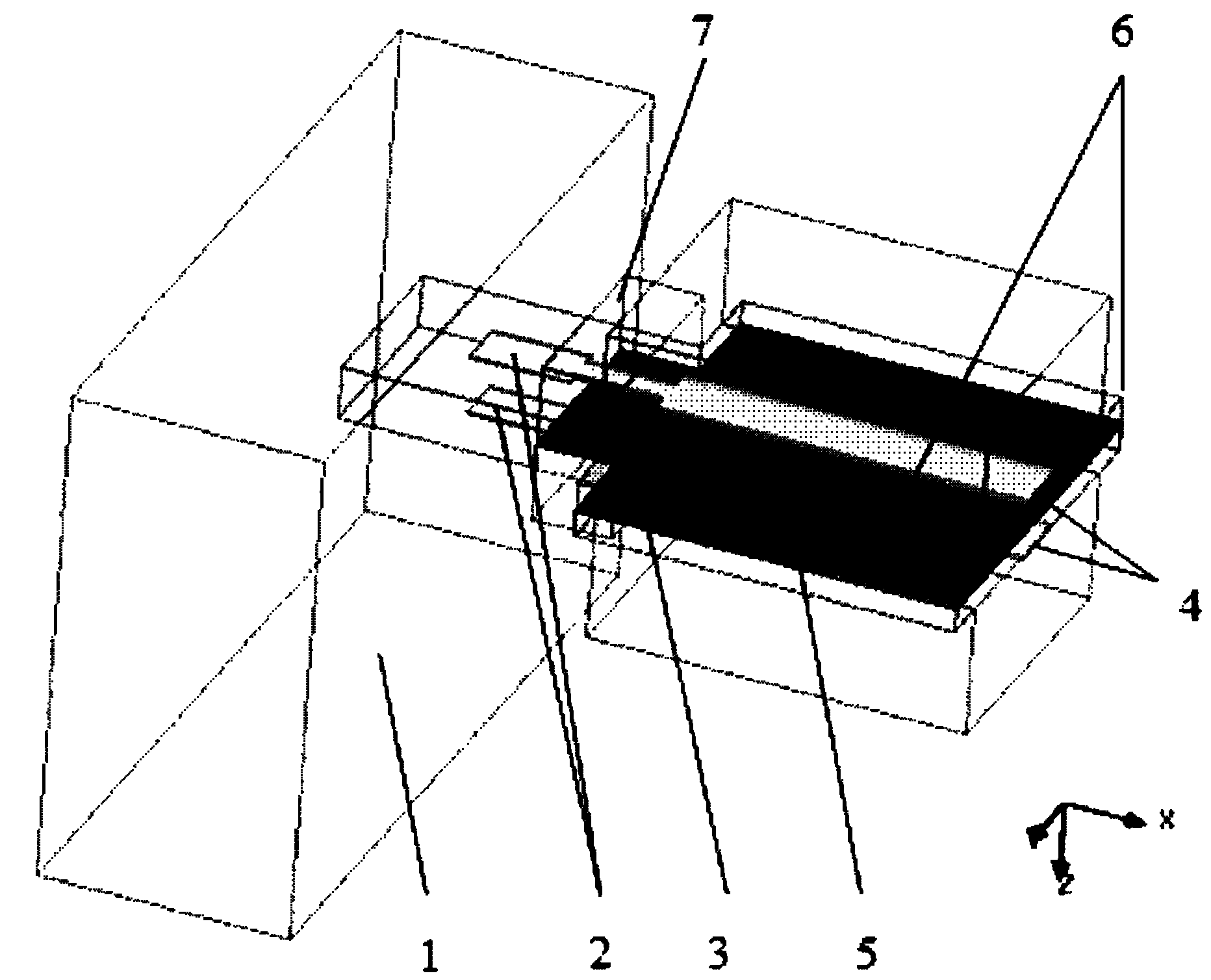

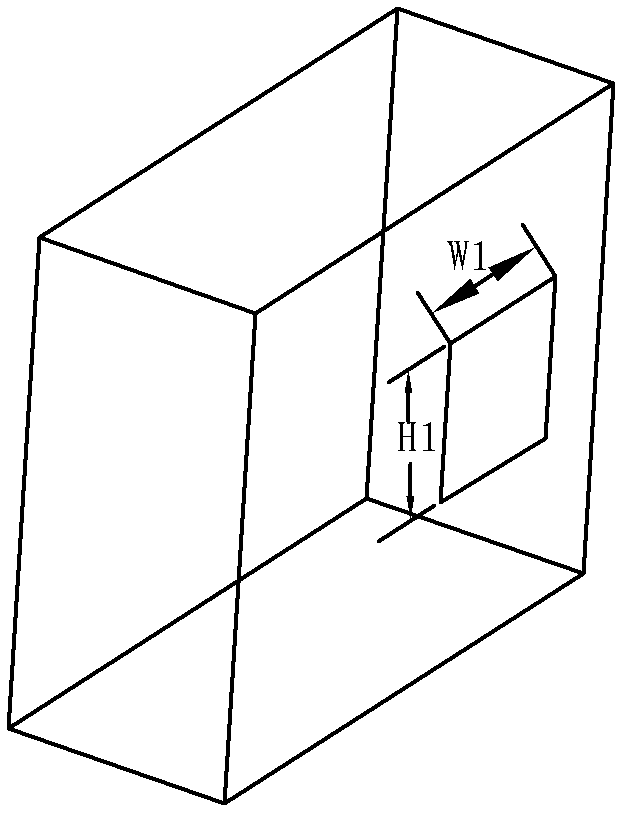

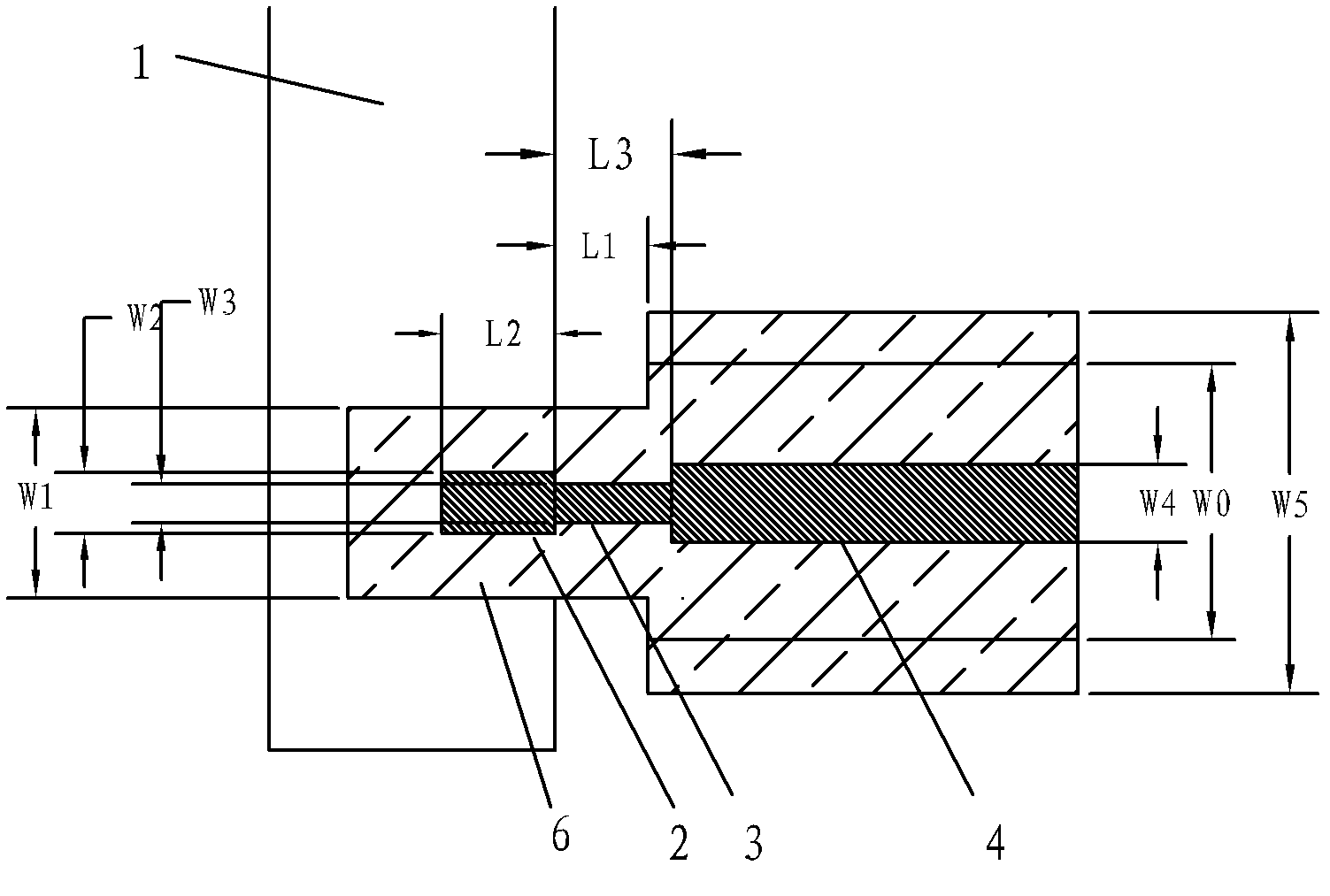

[0015] Such as figure 1 and figure 2 As shown, the waveguide-microstrip integrated power divider and combiner includes a rectangular waveguide 1, a dielectric substrate 6, and a common ground 5 embedded in the dielectric substrate 6, which is symmetrical with the common ground 5 and attached to the upper surface and the lower surface of the dielectric substrate 6. Two microstrip probes 2 on the surface, the two microstrip probes 2 are respectively connected to two groups of microstrip line impedance transformation sections 3 and two 50-ohm microstrip transmission lines 4 in sequence to form two groups of parallel and common ground 5 symmetrical microstrip lines respectively located on the upper surface and the lower surface of the dielectric substrate 6, the two microstrip probes 2 are vertically inserted into the rectangular waveguide 1 from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com