Laser beam applying mechanism and laser processing apparatus

一种照射机构、激光束的技术,应用在激光器、激光焊接设备、激光器零部件等方向,能够解决降低半导体芯片质量、妨碍激光光线、难以确实地除去测试用金属图案区域等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Next, preferred embodiments of the laser beam irradiation mechanism and the laser processing apparatus according to the present invention will be described in detail with reference to the accompanying drawings.

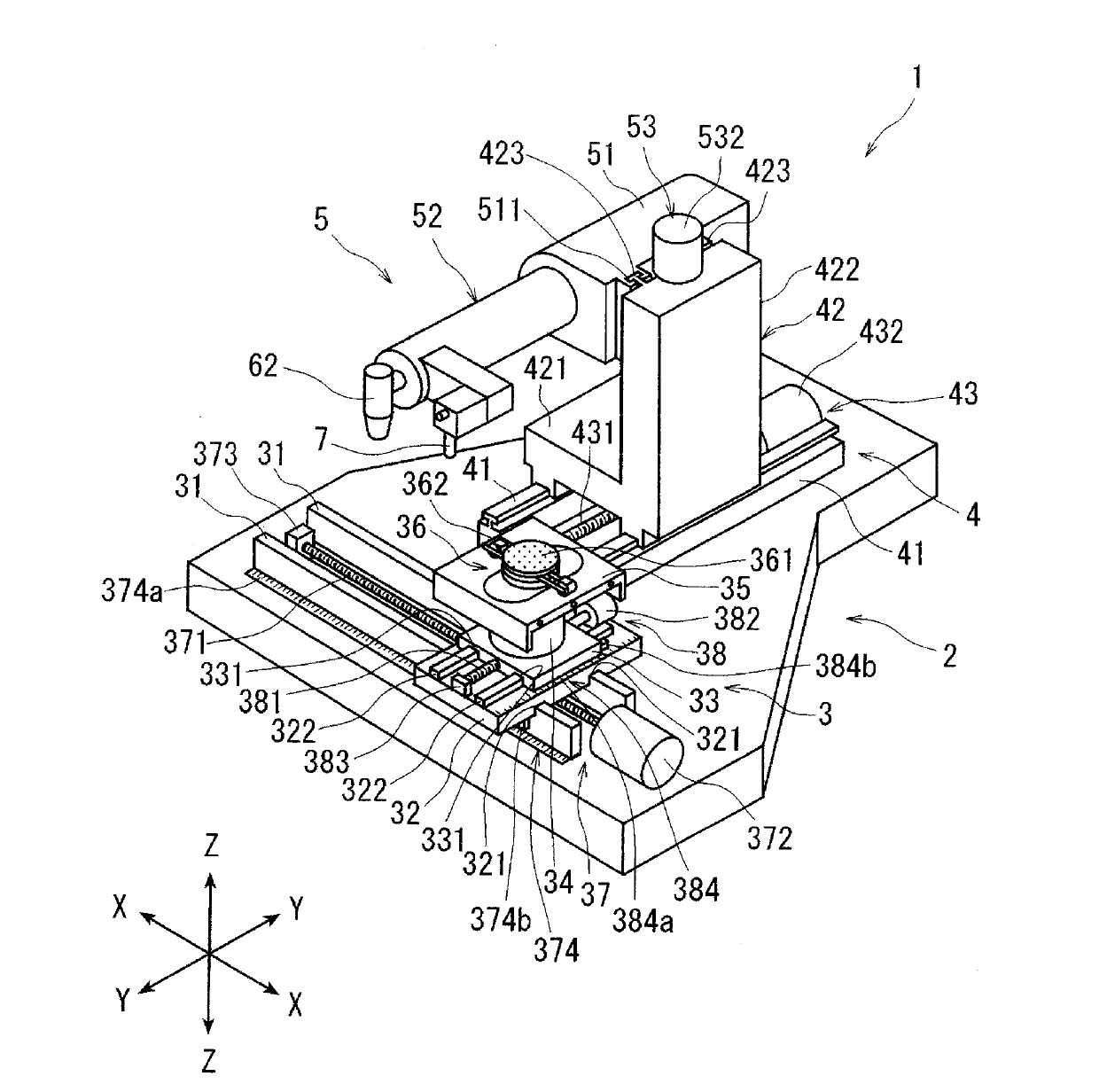

[0050] figure 1 It is a perspective view showing a laser processing apparatus equipped with a laser beam irradiation mechanism according to the present invention. figure 1 The illustrated laser processing apparatus 1 includes: a stationary base 2; a chuck table mechanism 3 arranged on the stationary base 2 so as to be movable in a machining feed direction (X-axis direction) indicated by an arrow X, Holding the workpiece; laser beam irradiation unit support mechanism 4, which is arranged on the stationary base so as to be movable in the index feed direction (Y-axis direction) indicated by arrow Y perpendicular to the X-axis direction 2; and a laser beam irradiation unit 5 disposed on the laser beam irradiation unit support mechanism 4 so as to be movable in a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com