Preparation method of ether amphoteric polycarboxylic acid water reducing agent

A technology of amphoteric polycarboxylic acid and water reducing agent, which is applied in the field of concrete admixture, can solve the problems of unsuitable water reducing agent application market, complex synthesis process, and expensive preparation cost, and achieve low cost, simple reaction equipment, and high slump retention sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

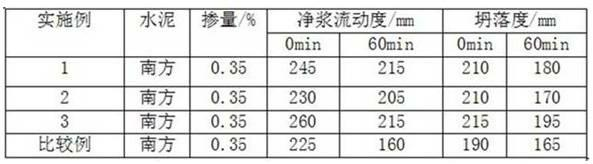

Examples

Embodiment 1

[0027] The first step: preparation of amidopolyamine

[0028] First, put 98kg of ethanolamine into the reaction kettle, start stirring and heat up, and add a small amount of glacial acetic acid as a dispersion medium and an acidulant. When the temperature reaches 45°C, add 0.66kg of p-toluenesulfonic acid while stirring, and stir evenly; then add maleic anhydride in three batches, 43kg each time, and control the temperature at 80°C during the feeding period; keep the system temperature at Insulate and react at 92°C for 5-7 hours, and stop the reaction when the acid value of the system remains unchanged. This reaction adopts p-toluenesulfonic acid as p-toluenesulfonic acid, glacial acetic acid as dispersion medium and acidifying agent, helps to improve reaction esterification rate and properly suppress amidation reaction, retains more amino groups in a small amount of maleic acid derivatives, will Helps improve the performance of amphoteric polycarboxylates.

[0029] The seco...

Embodiment 2

[0032] The first step: preparation of amidopolyamine

[0033] First, put 98kg of ethanolamine into the reaction kettle, start stirring and heat up, and add a small amount of glacial acetic acid as a dispersion medium and an acidulant. When the temperature reaches 45°C, add 0.66kg of p-toluenesulfonic acid while stirring, and stir evenly; then add maleic anhydride in three batches, 43kg each time, and control the temperature at 80°C during the feeding period; keep the system temperature at Insulate and react at 92°C for 5-7 hours, and stop the reaction when the acid value of the system remains unchanged. This reaction adopts p-toluenesulfonic acid as p-toluenesulfonic acid, glacial acetic acid as dispersion medium and acidifying agent, helps to improve reaction esterification rate and properly suppress amidation reaction, retains more amino groups in a small amount of maleic acid derivatives, will Helps improve the performance of amphoteric polycarboxylates.

[0034] The seco...

Embodiment 3

[0037] The first step: preparation of amidopolyamine

[0038] First, put 98kg of ethanolamine into the reaction kettle, start stirring and heat up, and add a small amount of glacial acetic acid as a dispersion medium and an acidulant. When the temperature reaches 45°C, add 0.66kg of p-toluenesulfonic acid while stirring, and stir evenly; then add maleic anhydride in three batches, 43kg each time, and control the temperature at 80°C during the feeding period; keep the system temperature at Insulate and react at 92°C for 5-7 hours, and stop the reaction when the acid value of the system remains unchanged. This reaction adopts p-toluenesulfonic acid as p-toluenesulfonic acid, glacial acetic acid as dispersion medium and acidifying agent, helps to improve reaction esterification rate and properly suppress amidation reaction, retains more amino groups in a small amount of maleic acid derivatives, will Helps improve the performance of amphoteric polycarboxylates.

[0039] The seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com