Sodium persulfate microcapsule capable of controllable concentrated release at fixed time and preparation method thereof

A technology of sodium persulfate and microcapsules, which is applied in the field of chemical materials, oil fields, and polymer gel water plugging operations in oil fields. It can solve the problems of short controlled release time and achieve the effects of low cost, simple operation, and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

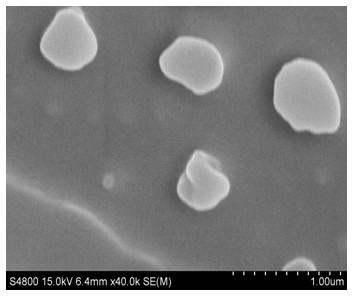

Image

Examples

Embodiment Construction

[0015] 1. Weigh each raw material with the following schemes:

[0016] Scheme 1: Liquid paraffin: 13.2%, sodium persulfate: 7.1%, cetyltrimethylammonium bromide: 0.71%, styrene: 5.7%, vinyl acetate: 1.3%, methacrylic acid: 0.14%, The rest is chloroform, totaling 100%.

[0017] Scheme 2: Liquid paraffin: 13%, sodium persulfate: 13%, cetyltrimethylammonium bromide: 0.65%, styrene: 6.8%, vinyl acetate: 1.6%, methacrylic acid: 0.17%, The rest is chloroform, totaling 100%.

[0018] Scheme 3: liquid paraffin: 7.8%, sodium persulfate: 7.8%, cetyltrimethylammonium bromide: 0.8%, styrene: 5%, vinyl acetate: 1.1%, methacrylic acid: 0.12%, The rest is chloroform, totaling 100%.

[0019] Scheme 4: liquid paraffin: 7.7%, sodium persulfate: 7.7%, cetyltrimethylammonium bromide: 0.8%, styrene: 5.5%, vinyl acetate: 1.25%, methacrylic acid: 0.14%, The rest is chloroform, totaling 100%.

[0020] Scheme 5: Liquid paraffin: 14.1%, sodium persulfate: 7%, cetyltrimethylammonium bromide: 0.7%, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com