Preparation method of decolorized squid skin collagen

A technology for skin collagen and squid skin, which is applied in the field of protein materials in biotechnology, can solve the problems of difficult removal of activated carbon, limited application of collagen peptides, and influence on collagen processing, etc., and achieves improved processing and utilization level, good decolorization effect, and collagen loss rate. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0011] The present invention is the preparation method of decolorized squid skin collagen, and its steps are:

[0012] (1) Take relatively complete frozen squid skin, wash it with deionized water, and dry it naturally;

[0013] (2) Get dried squid skin, be placed in the container, add the potassium permanganate solution that concentration is 1%, be 1: 20~30 ratio g / ml by the quality of squid skin and the volume ratio g / ml of potassium permanganate solution Determine the volume of the potassium permanganate solution added, stir evenly, and the stirring time lasts 60 minutes;

[0014] (3) remove the potassium permanganate solution in the container, clean the squid skin 3 times, then put the squid skin in the container, add the oxalic acid solution that the concentration is 8%, press the quality of the squid skin and the volume ratio of the oxalic acid solution The ratio of g / ml is 1:20-30 to determine the volume of the added oxalic acid solution, stir evenly, and the stirring t...

Embodiment 1

[0018] Take 50 g of dried squid skin, place it in a container, add 1 L of 1% potassium permanganate solution, and stir evenly for 60 minutes with an electric stirrer at a speed of 50 to 60 rpm. Remove the potassium permanganate solution in the container, wash the squid skin with 250ml of distilled water for 3 times, then place it in the container, add 1L of oxalic acid solution with a concentration of 8%, and stir evenly with an electric stirrer at a speed of 50-60 rpm 6 hours. Remove the oxalic acid solution in the container, and squid skin is cleaned 3 times with 250ml distilled water. Homogenize the squid skin, place it in a container, add 1L of distilled water, and then add 0.25g trypsin, then place the container where the squid skin is placed in a water bath with a constant temperature of 45°C, and hydrolyze it for 2 hours to obtain a decolorized collagen solution. The decolorized collagen solution was freeze-dried in a vacuum freeze dryer.

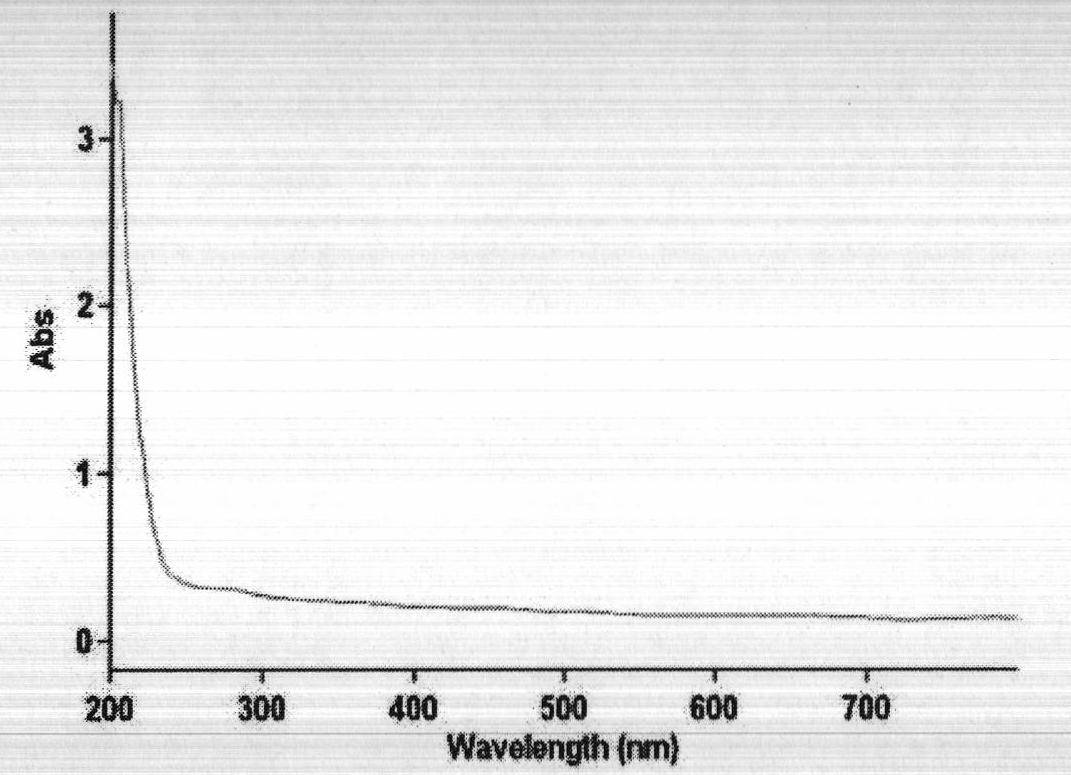

[0019] (1) if figure 1 , ...

Embodiment 2

[0031] Take 500 g of dried squid skin, place it in a container, add 10 L of 1% potassium permanganate solution, and stir evenly for 60 minutes with an electric stirrer at a speed of 50 to 60 rpm. Remove the potassium permanganate solution in the container, wash the squid skin with 2500ml of distilled water for 3 times, then place it in the container, add 10L of oxalic acid solution with a concentration of 8%, and stir evenly with an electric stirrer at a speed of 50-60 rpm 6 hours. Remove the oxalic acid solution in the container, and squid skin is cleaned 3 times with 2500ml distilled water. Homogenize the squid skin, place it in a container, add 1L of distilled water, and then add 2.5g of trypsin, place the container containing the squid skin in a water bath at a constant temperature of 45°C, and hydrolyze it for 2 hours to obtain the final decolorizing solution. The collagen solution was freeze-dried in a vacuum freeze dryer.

[0032] (1) if Figure 5 , Figure 6 As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com