Stack type battery and method of manufacturing the same

A stacked, stacked electrode technology, which is applied in secondary battery manufacturing, secondary batteries, lithium batteries, etc., can solve problems such as damage to composite exterior bodies, small holes, and easy short circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0107] [production of positive electrode]

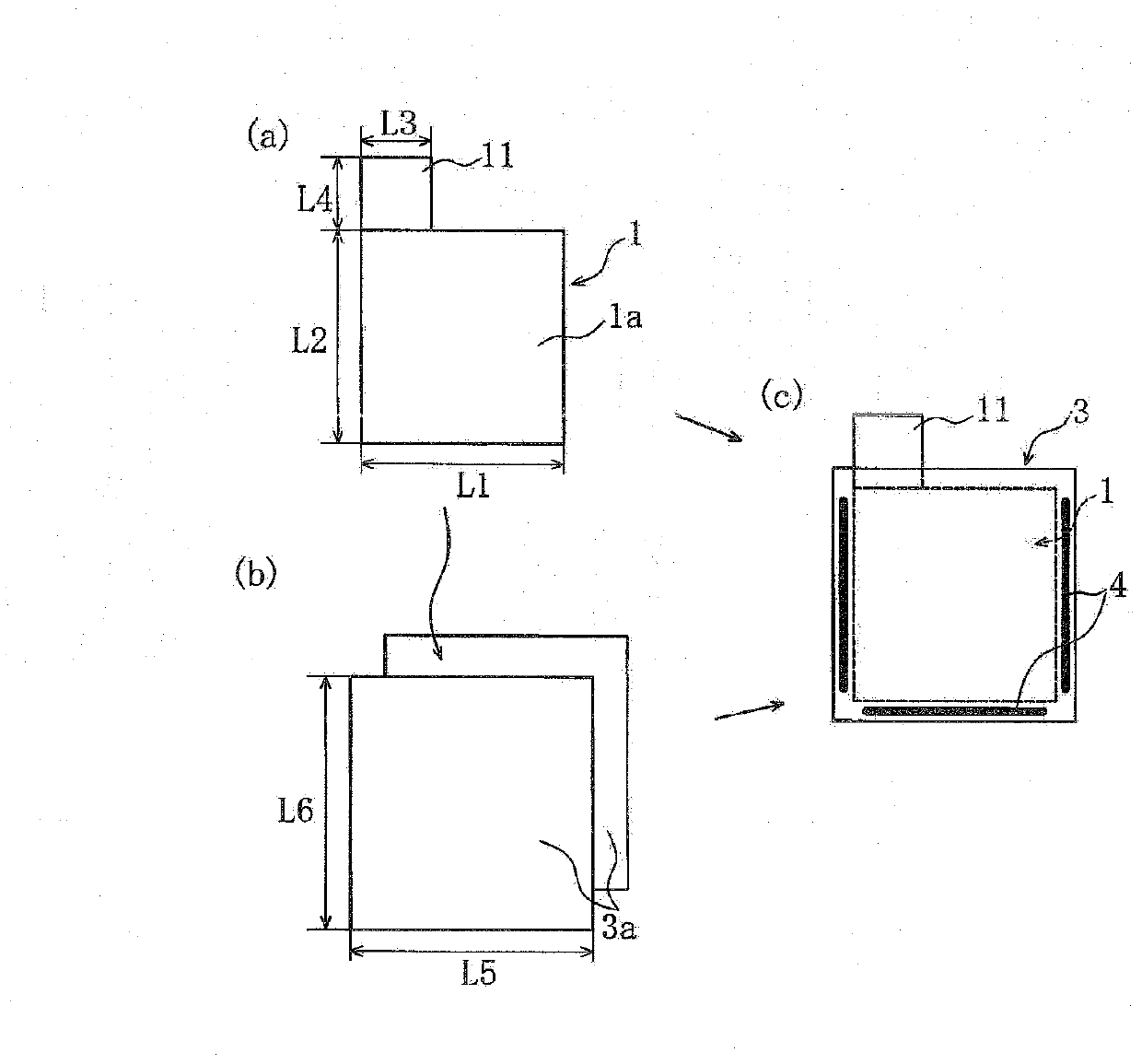

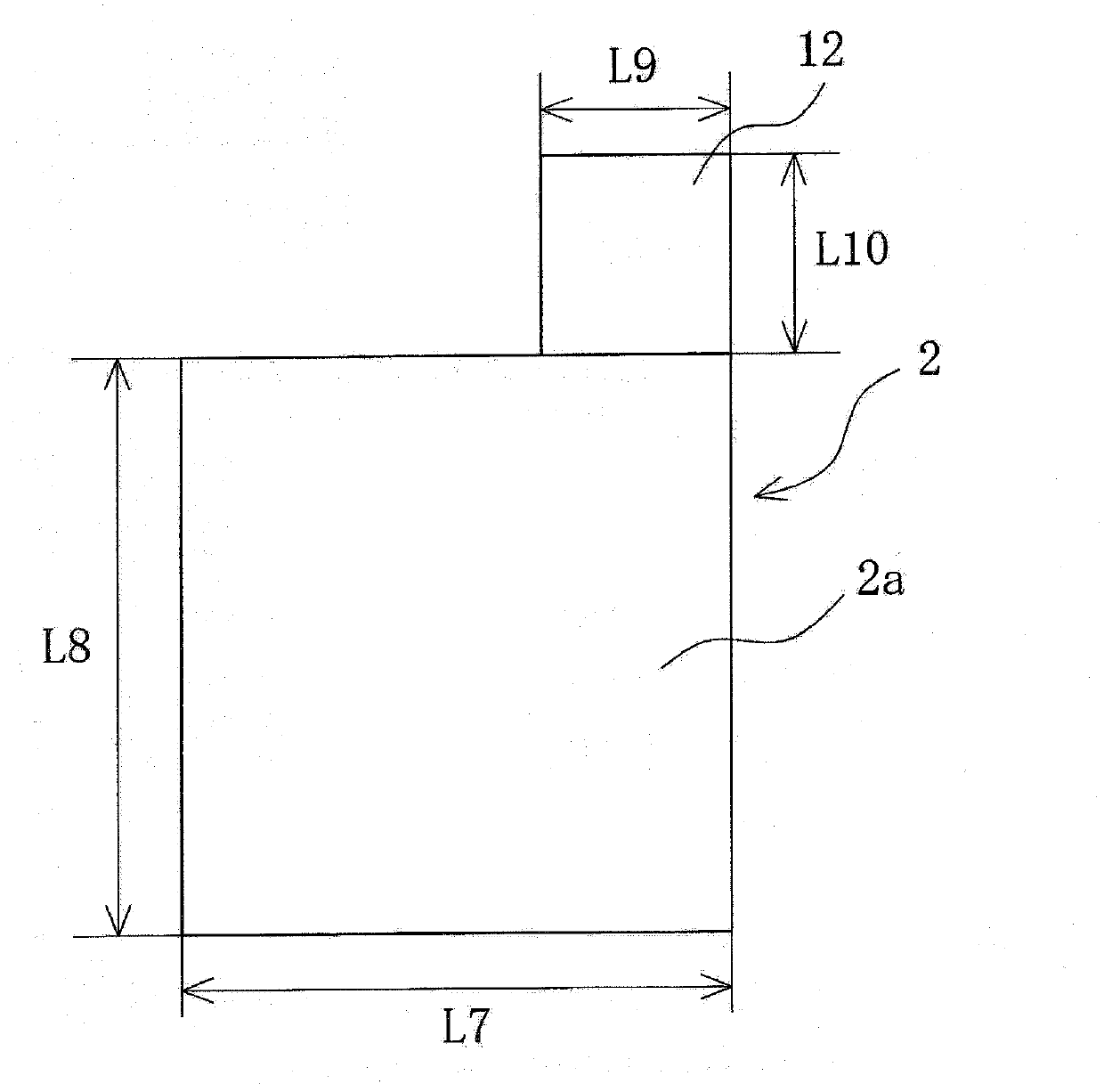

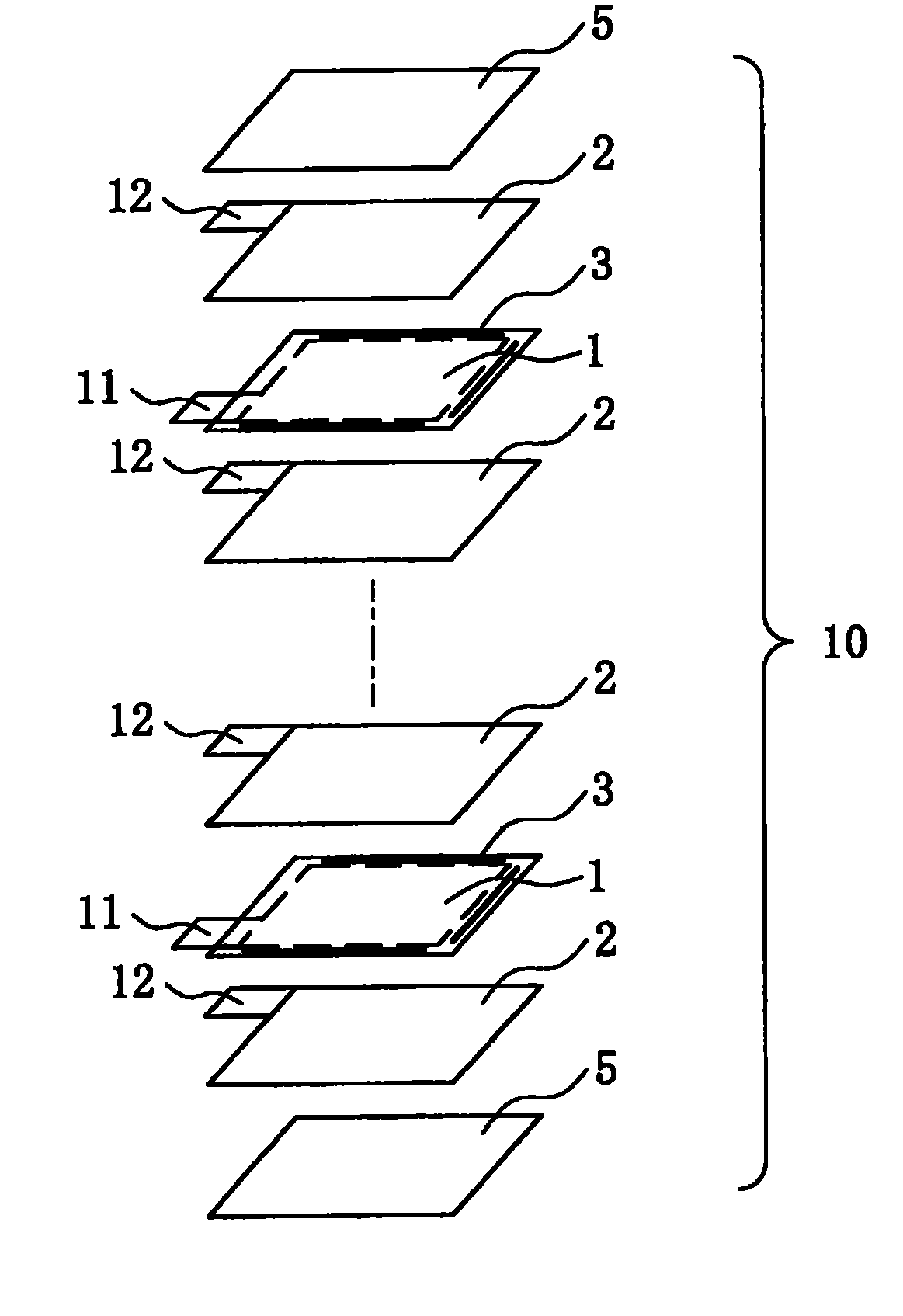

[0108] 90% by mass of LiCoO as the positive electrode active material 2 , 5% by mass of carbon black as a conductive agent, 5% by mass of polyvinylidene fluoride as a binder, and N-methyl-2-pyrrolidone (NMP) solution as a solvent were mixed to prepare a positive electrode slurry. This positive electrode slurry was applied to both surfaces of an aluminum foil (thickness: 15 μm) as a positive electrode current collector. Then, after drying the solvent by heating and compressing it to a thickness of 0.1mm by rollers, as figure 1 As shown in (a), the positive electrode plate 1 having the positive electrode active material layer 1 a on both surfaces was produced by cutting into a width L1 = 85 mm and a height L2 = 85 mm. At this time, make the active material uncoated part of width L3=30mm, height L4=20mm from one end of one side extending along the width L1 direction of the positive electrode plate 1 ( figure 1 In (a), the left end ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com