Production method of Tibetan mushroom yogurt

A production method, the technology of mushroom acid, applied in the field of bioengineering, can solve the problems of large number of mushrooms in Tibet, large amount of inoculation, and difficulty in large-scale production, and achieve fine and uniform texture, shortened fermentation cycle, and good solidification state Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

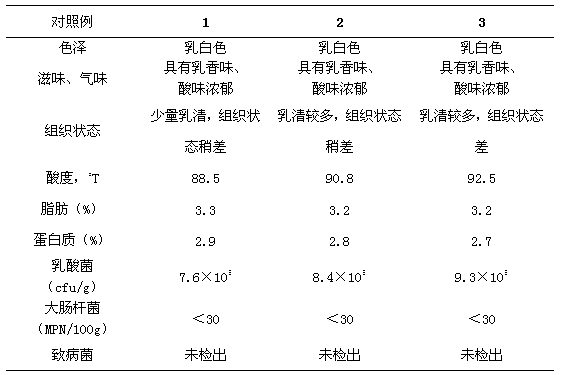

Examples

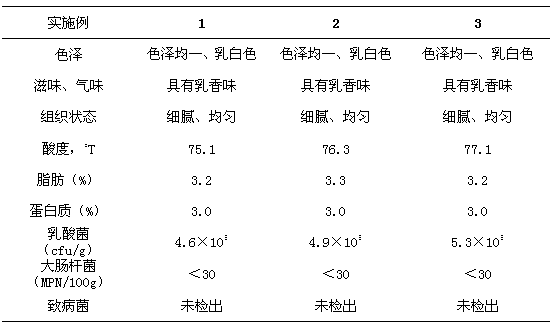

Embodiment 1

[0025] Filter the milk that has passed the inspection through a tubular filter, raise the temperature to 60°C, add 0.5% yogurt stabilizer (ZG-20 type, Changsha Richengsheng Food Additives Factory) and the mass percent The 7% sucrose is mixed and added through a mixer, and then passed through a colloid mill with a cycle time of 15 minutes to ensure that the excipients are fully dissolved. Homogenization is carried out in a homogenizer at a temperature of 60° C. and a pressure of 18 MPa. Sterilize the homogenized milk at 95°C for 5 minutes, then cool it down to 37°C for later use. The sterilized milk is divided into three parts, one part is used to make starter, one part is used to make expanded starter, and one part is used for inoculation fermentation.

[0026] Inoculate Tibetan Linggu with 3% inoculation amount into cooled pasteurized milk, stir for 10 minutes every hour, cultivate at 37°C for 8 hours, and filter the mushroom body to obtain a starter. The starter was inocul...

Embodiment 2

[0031] Filter the milk that has passed the inspection through a tubular filter, raise the temperature to 65°C, add 0.5% yogurt stabilizer (ZG-20 type, Changsha Richengsheng Food Additives Factory) and the mass percent The 7% sucrose is mixed and added through a mixer, and then passed through a colloid mill with a cycle time of 20 minutes to ensure that the excipients are fully dissolved. Homogenization is carried out in a homogenizer at a temperature of 65° C. and a pressure of 20 MPa. Sterilize the homogenized milk at 98°C for 10 minutes, then cool it down to 37°C for later use. The sterilized milk is divided into three parts, one part is used to make starter, one part is used to make expanded starter, and one part is used for inoculation fermentation.

[0032] Inoculate Tibetan Linggu with 4% inoculum amount into cooled pasteurized milk, stir for 15 minutes every hour, incubate at 37°C for 9 hours, and filter the mushroom body to obtain a starter. The starter was inoculate...

Embodiment 3

[0037] Filter the milk that has passed the inspection through a tubular filter, raise the temperature to 62°C, add a yogurt stabilizer (ZG-20 type, Changsha Richengsheng Food Additives Factory) with a mass percentage of 0.5% and the mass percentage The 7% sucrose is mixed and added through a mixer, and then passed through a colloid mill with a cycle time of 18 minutes to ensure that the excipients are fully dissolved. Homogenization is carried out in a homogenizer at a temperature of 62° C. and a pressure of 19 MPa. Sterilize the homogenized milk at 96°C for 8 minutes, then cool it down to 37°C for later use. The sterilized milk is divided into three parts, one part is used to make starter, one part is used to make expanded starter, and one part is used for inoculation fermentation.

[0038]Inoculate Tibetan Linggu with 5% inoculum amount into cooled pasteurized milk, stir for 12 minutes every hour, incubate at 37°C for 9 hours, and filter the mushroom body to obtain a starte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com