Compound liquid dairy product with function of assisting in reducing blood fat and preparation method thereof

A dairy product and liquid technology, which is applied in the field of compound liquid dairy products and its preparation, can solve the problems of unfavorable realization and high cost of raw materials, and achieve the effect of synergistic function and blood fat lowering function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0074] In one embodiment, the present invention provides a method for preparing a compound liquid dairy product. Through appropriate chemical process, phytosterol esters are melted in a water bath at 50°C-80°C and then added to hot milk. Add it to cold milk at ≤ 15°C, and further go through rapid homogenization, pasteurization, ultra-high temperature sterilization and other processes to achieve maximum protection for compound preparations of phytosterol esters and linolenic acid oil, ensuring good taste and shelf life of the product internal stability.

[0075] Preferably, the method of the invention is used to produce the product of the invention described above.

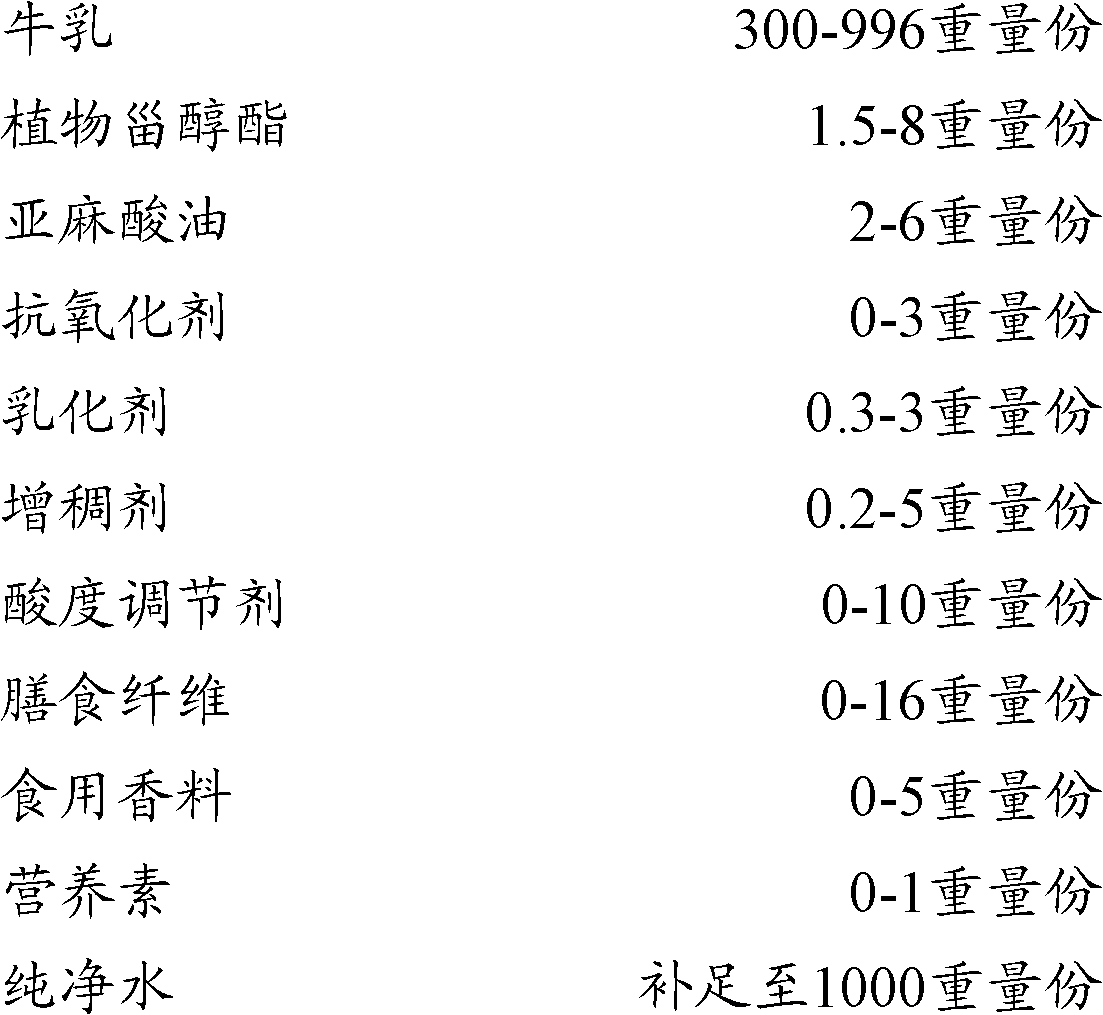

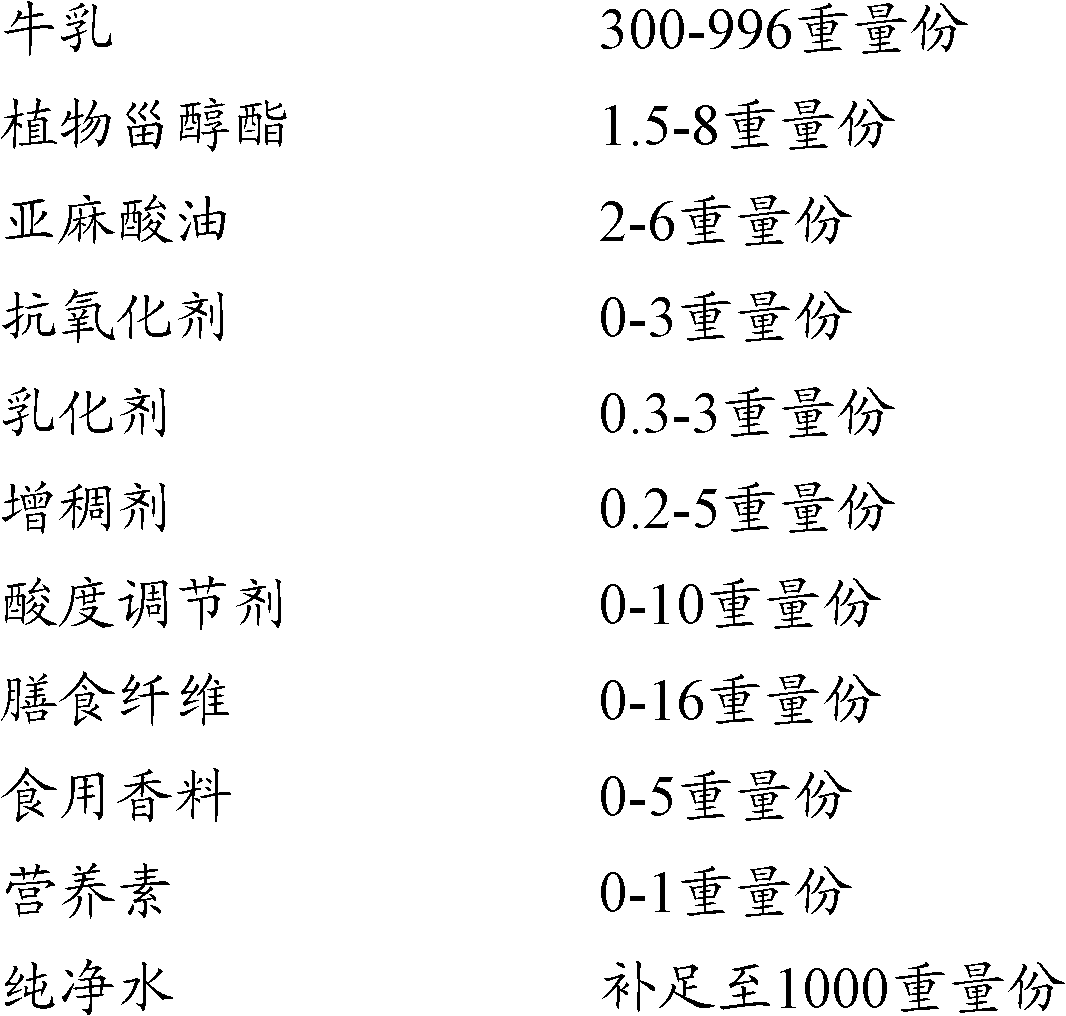

[0076] In the above-mentioned production process, the composition of the obtained compound liquid milk product is as follows:

[0077]

[0078]

[0079] Known technologies related to the present invention are described in, for example, "Milk and Dairy Products Technology", Luo Chengxiang, China Agricultural ...

Embodiment 1

[0215] Preparation of high-protein supplemented blood-fat-lowering milk

[0216] Recipe:

[0217]

[0218]

[0219] Concrete preparation process is as follows:

[0220] 1. Raw milk: sourced from self-owned pastures, in compliance with GB 19301 regulations.

[0221] 2. Ingredients:

[0222] 2.1. Phytosterol ester melting:

[0223] Place the sealed barreled raw materials in a constant temperature water bath at 50-60°C for soaking 2-4 hours before batching (the water level cannot exceed the upper edge of the raw material barrel). After soaking, open the lid to check that the raw material melts into a uniform and clear liquid before feeding. If it is not melted to the above state, close the lid tightly and continue soaking until it is completely melted.

[0224] 2.2. Chemical material 1

[0225] Slowly heat up to 35-40°C in the stirring state, turn on the high-speed mixer, add phytosterol esters, emulsifiers, thickeners, dietary fiber, food flavors, and antioxidants i...

Embodiment 2

[0286] Example 2: Preparation of Modified Milk with Auxiliary Lowering Blood Fat

[0287] Recipe:

[0288]

[0289] The specific operations of the preparation process are as follows:

[0290] 1. Raw milk: comply with the provisions of GB 19301.

[0291] 2. Ingredients:

[0292] 2.1. Phytosterol ester melting:

[0293] Place the sealed barreled raw materials in a constant temperature water bath at 50-60°C for soaking 2-4 hours before batching (the water level cannot exceed the upper edge of the raw material barrel). After soaking, open the lid to check that the raw material melts into a uniform and clear liquid before feeding. If it is not melted to the above state, close the lid tightly and continue soaking.

[0294] 2.2. Chemical material 1

[0295] The stirring state is heated to 45-50°C, and the molten state phytosterol ester, emulsifier, antioxidant, thickener, and acidity regulator are 85-90°C (heating rate≤2°C / min), and stirred for 3-15 minutes to make The raw m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com