Carbon nanotube supported catalyst and preparation method thereof as well as application of carbon nanotube supported catalyst in low-temperature catalytic oxidation of CO

A supported catalyst, carbon nanotube technology, applied in the field of environment and public safety, can solve the problems of limited material adsorption capacity and rate, unsuitable closed space CO removal, complicated operation and system, etc., to achieve high catalytic activity and stability. performance, low cost and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035]Correspondingly, the present invention provides a method for preparing a carbon nanotube-supported catalyst, comprising the following steps: mixing the carbon nanotubes with an impregnation solution containing copper salt and manganese salt to obtain a mixture; drying the mixture and then roasting , to obtain carbon nanotube-supported catalysts.

[0036] The method for preparing the carbon nanotube-loaded catalyst of the invention is a simple impregnation method, is easy to operate, and is suitable for industrial popularization and application.

[0037] In the embodiment of the present invention, the impregnating liquid can be prepared first: according to the molar ratio of the active components, a certain mass of copper salt and manganese salt are respectively weighed and dissolved in water to obtain a (mixed) impregnating liquid containing copper salt and manganese salt. Specifically, copper and manganese salts can be dissolved in 200mL of deionized water, and the cons...

Embodiment 1

[0050] The catalyst of this embodiment uses carbon nanotube material (MWCNTs) as the carrier, and the acetate of copper and manganese is the precursor of the active component. The corresponding copper-manganese composite oxide loading on the carrier is 8%, wherein copper, manganese The molar ratio of manganese acetate is 1:1.

[0051] The concrete preparation method that this embodiment relates to catalyst is:

[0052] Step 1: Weigh 96.0g of carbon nanotubes, place them in a constant temperature drying oven, and dry them at 85°C for 4 hours;

[0053] Step 2: take by weighing 10.0g copper acetate (C 4 h 6 CuO 4 ·H 2 O) and 12.3g manganese acetate (C 4 h 6 MnO 4 4H 2 (2) was dissolved in 200mL deionized water, and was continuously stirred in a constant temperature water bath for 2h to prepare a mixed impregnation solution with a concentration of 0.5mol / L;

[0054] Step 3: adding the dried and pretreated carbon nanotubes in step 1 to the mixed impregnating solution prepa...

Embodiment 2

[0064] The catalyst in this embodiment uses carbon nanotube material as the carrier, copper and manganese acetate as the active component precursor, and the corresponding copper-manganese composite oxide loading on the carrier is 8%, wherein copper and manganese acetate The molar ratio of acid salt is 1:8.

[0065] The concrete preparation method that this embodiment relates to catalyst is:

[0066] Step 1: Weigh 99.1g of carbon nanotube carrier and place it in a constant temperature drying oven, and dry it at 105°C for 4 hours;

[0067] Step 2: take by weighing 2.2g copper acetate (C 4 h 6 CuO 4 ·H 2 O) and 21.8g manganese acetate (C 4 h 6 MnO 4 4H 2 (2) was dissolved in 200mL deionized water, and was continuously stirred in a constant temperature water bath for 2h to prepare a mixed impregnation solution with a concentration of 0.5mol / L;

[0068] Step 3: adding the dry and pretreated carbon nanotube carrier in step 1 to the mixed impregnation solution prepared in step...

PUM

| Property | Measurement | Unit |

|---|---|---|

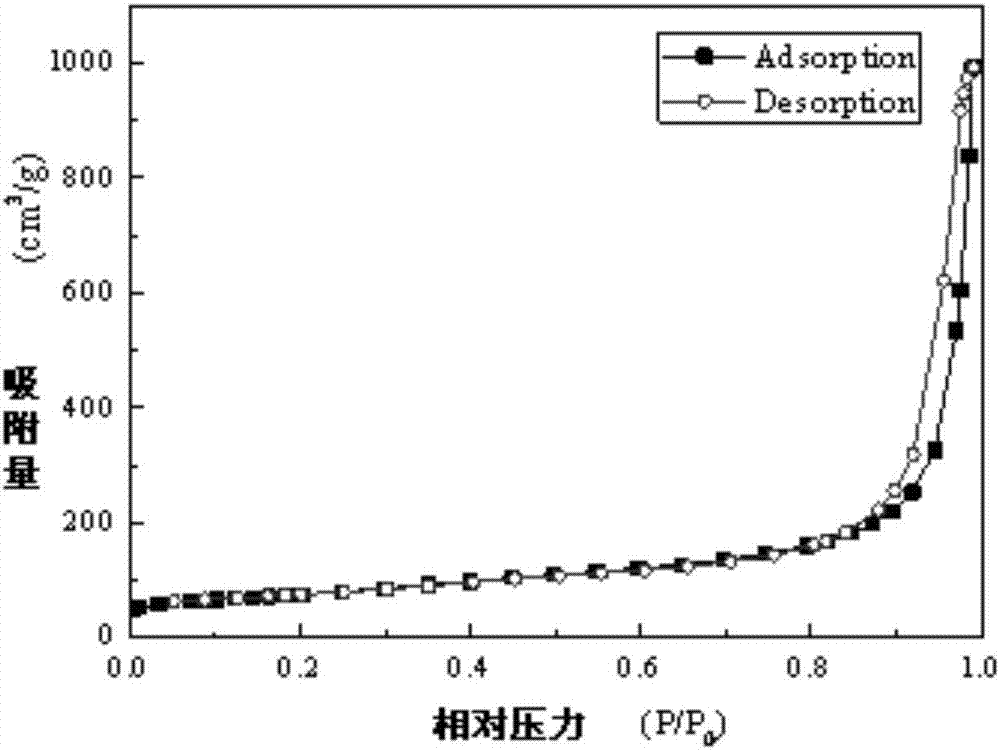

| specific surface area | aaaaa | aaaaa |

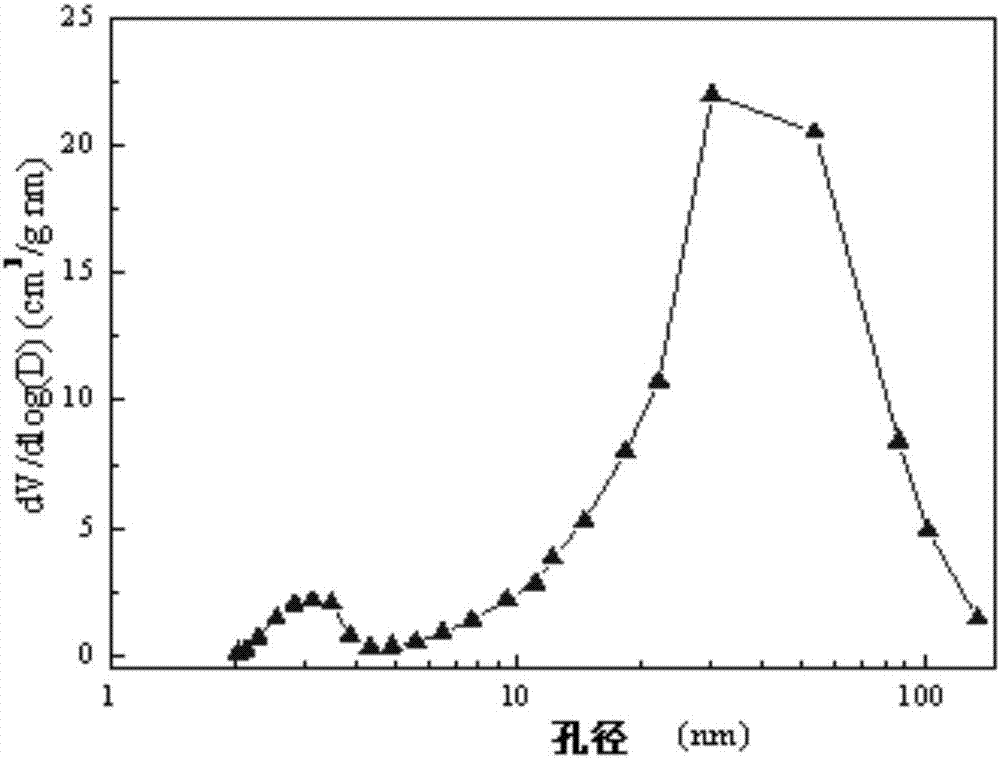

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com