N-doped nano-TiO2 and shock wave preparation method thereof

A shock wave and nanotechnology, which is applied in the field of N-doped nano-TiO2 and its shock wave preparation, can solve the problems of high-efficiency absorption of difficult visible light and low element doping, and achieve the effect of simple process, low cost and good visible light catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A kind of N-doped nano-TiO 2 The shock wave preparation method, described method process is as follows:

[0030] Step 1, metatitanic acid (H 2 TiO 3 ) and dicyandiamide (C 2 N 4 h 4 ) after uniform mixing, mechanical ball milling for 10 min to obtain mixed powder;

[0031] Wherein, the quality of metatitanic acid: the quality=4:1 of dicyandiamide;

[0032] Step 2, pressing the mixed powder into a blank, the density of the blank is 55%;

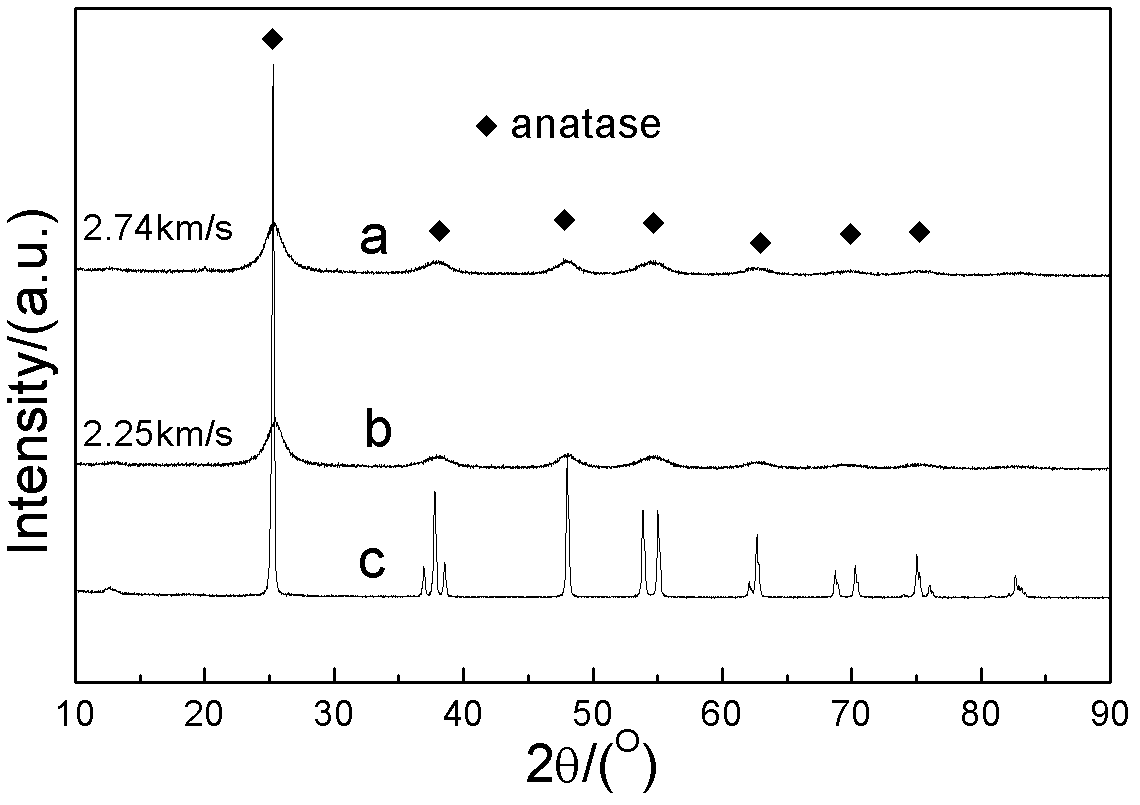

[0033] Step 3. Hit the preform with flying pieces driven by explosive detonation, and use the instantaneous high temperature and high pressure induced by the impact to obtain N-doped nano-TiO 2 ;

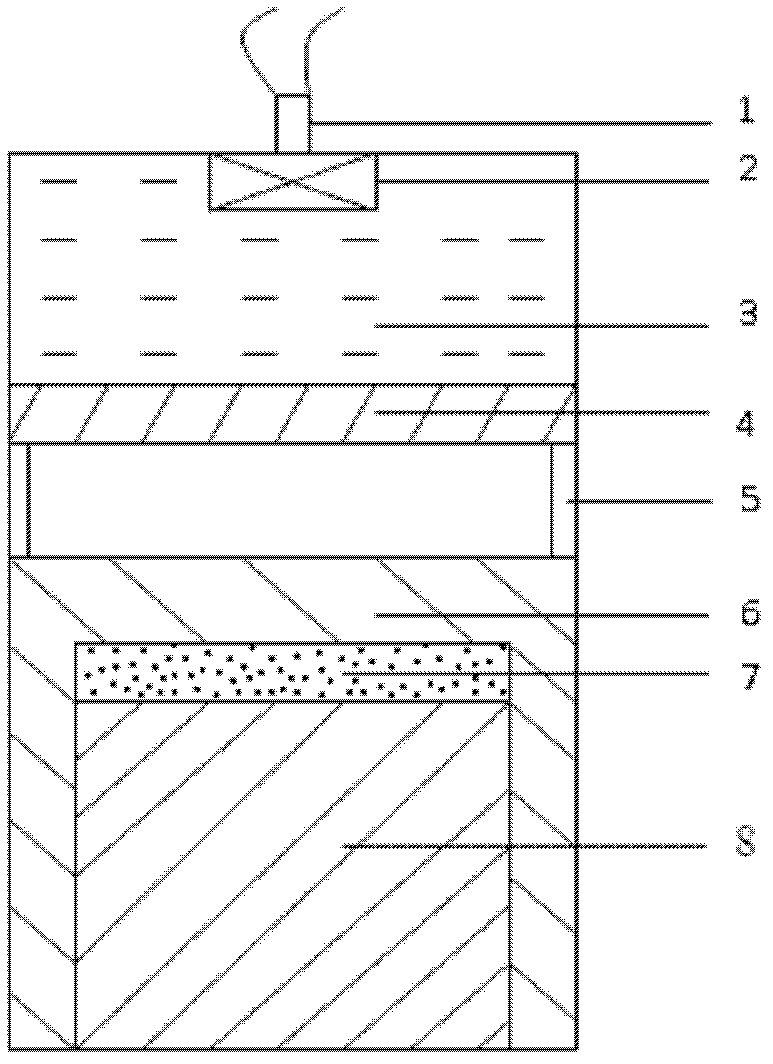

[0034] Among them, such as figure 1 As shown, N-doped nano-TiO was prepared by shock wave 2 The device comprises: flyer drive unit, sample box unit and support 5; Wherein the flyer drive unit includes detonator 1, booster charge 2, explosive 3 and flyer 4; Sample box unit includes sample box 6 and stopper 7; In the flyer drive unit...

Embodiment 2

[0042] A kind of N-doped nano-TiO 2 The shock wave preparation method, described method process is as follows:

[0043] Step 1, metatitanic acid (H 2 TiO 3 ) and dicyandiamide (C 2 N 4 h 4 ) after uniform mixing, mechanical ball milling for 10 min to obtain mixed powder;

[0044] Wherein, the quality of metatitanic acid: the quality=7:3 of dicyandiamide;

[0045] Step 2, pressing the mixed powder into a blank, the density of which is 45%;

[0046] Step 3. Hit the preform with flying pieces driven by explosive detonation, and use the instantaneous high temperature and high pressure induced by the impact to obtain N-doped nano-TiO 2 ;

[0047] Preparation of N-doped Nano TiO by Shock Wave 2 The device is the same as in Example 1; the specific process is: the compacted blank 7 is packed into the sample box 6, and the blank 7 is fixed with a plug, and the sample box 6 and the plug 8 are in close contact with the blank 7; The flyer drive unit is installed on the support 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com