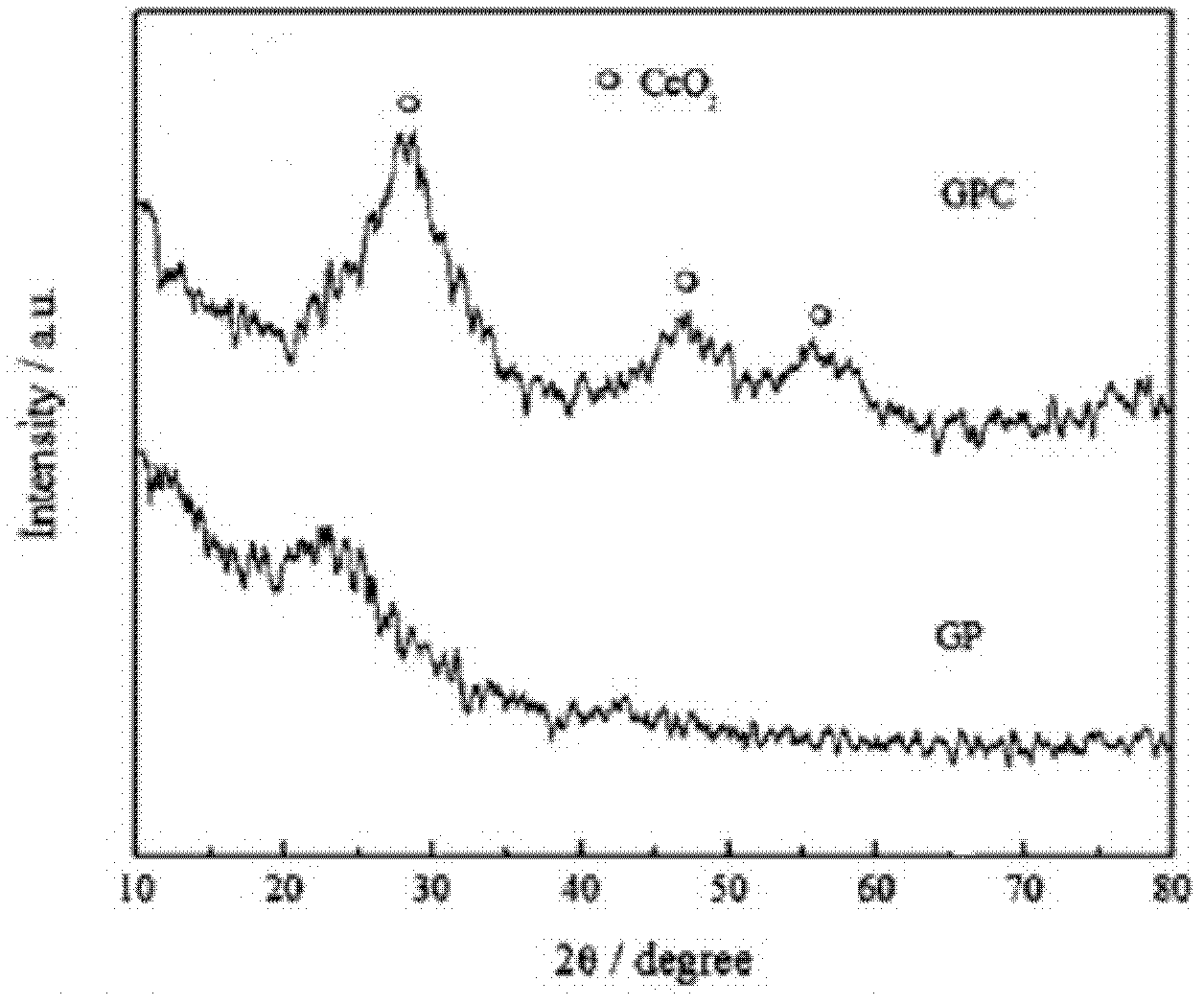

Preparation method of graphene supported cerium oxide nano cubit compound

A technology of ceria and nanocubic, which is applied in the field of preparation of ceria nanocubic composites, can solve the problems of different nanoparticle shapes, poor crystallinity, uneven particles, etc., and achieve the effect of simple and fast preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1. Dissolve 20mg of GO powder in 40mL of deionized water and ultrasonically disperse for 2h, the solution turns translucent bright brown and is evenly dispersed.

[0025] 2. Add 434.2mg Ce(NO 3 ) 3 ·6H 2 O crystals, stir well until there are no crystal particles in the solution.

[0026] 3. Then inject 1ml of NH into the above solution 3 ·H 2 O solution.

[0027] 4. Pour the stirred mixed solution into a reaction kettle, place it in a vacuum oven and heat at 220° C. for 24 hours.

[0028] 5. Repeatedly vacuum filter the reacted solution with deionized water until the solution becomes neutral.

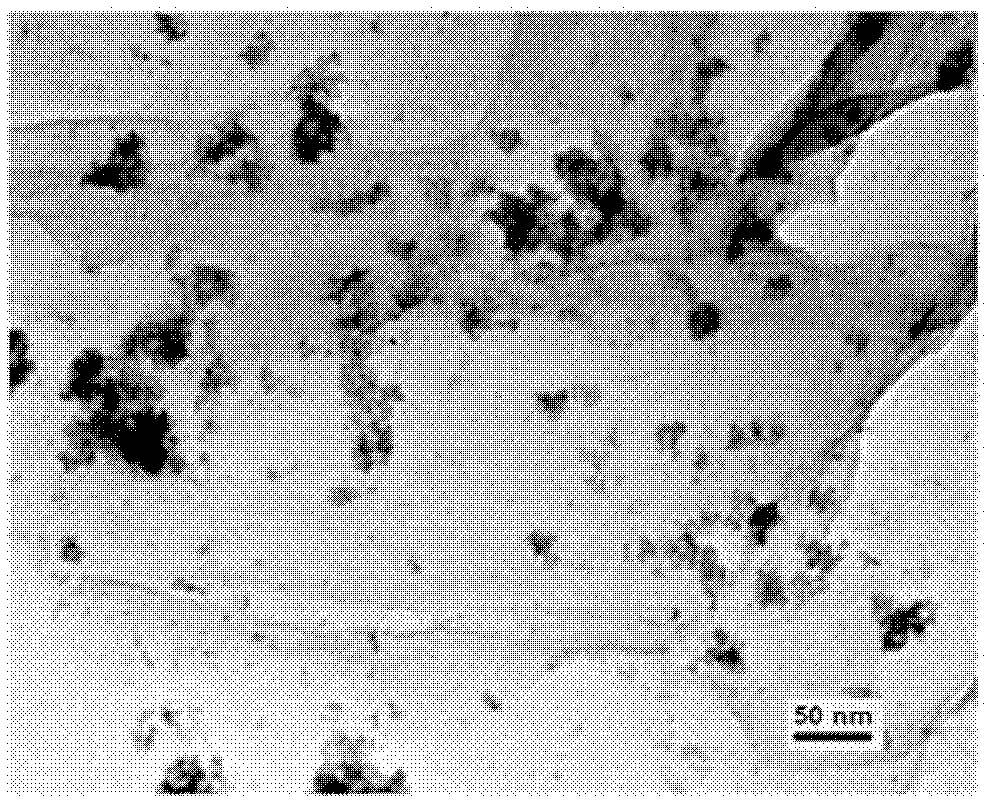

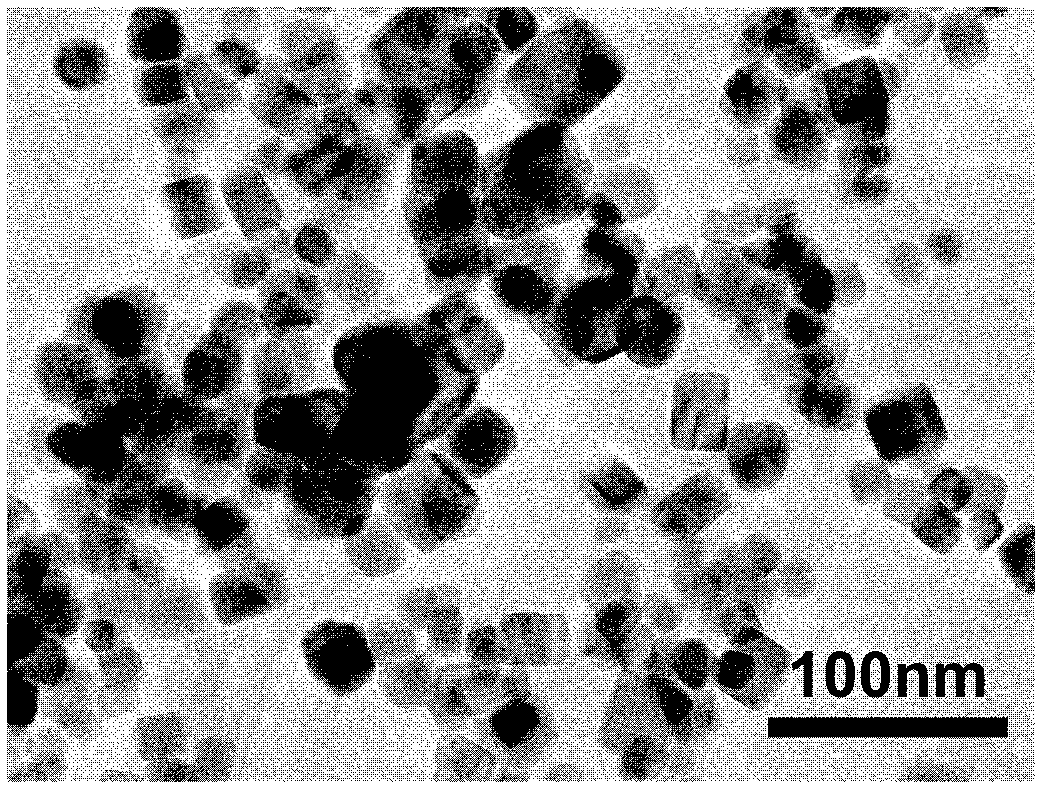

[0029] 6. Finally, dry the obtained powder in the air at 50° C. for 48 hours to obtain a graphene-supported ceria nanocubic composite with (200) exposed surfaces.

Embodiment 2

[0031] 1. Dissolve 20mg of GO powder in 40mL of deionized water and ultrasonically disperse for 2h, the solution turns translucent bright brown and is evenly dispersed.

[0032] 2. Add 217.1mg Ce(NO 3 ) 3 ·6H 2 O crystals, stir well until there are no crystal particles in the solution.

[0033] 3. Then inject 1ml of NH into the above solution 3 ·H 2 O solution.

[0034] 4. Pour the stirred mixed solution into a reaction kettle, place it in a vacuum oven and heat at 240° C. for 12 hours.

[0035] 5. Repeatedly vacuum filter the reacted solution with deionized water until the solution becomes neutral.

[0036] 6. Finally, dry the obtained powder in the air at 100°C for 6 hours to obtain a graphene-supported ceria nanocubic composite with (200) exposed surfaces

Embodiment 3

[0038] 1. Dissolve 20mg of GO powder in 60mL of deionized water and ultrasonically disperse for 2h, the solution becomes translucent bright brown and dispersed evenly.

[0039] 2. Add 868.4mg Ce(NO 3 ) 3 ·6H 2 O crystals, stir well until there are no crystal particles in the solution.

[0040] 3. Then inject 3ml of NH into the above solution 3 ·H 2 O solution.

[0041] 4. Pour the stirred mixed solution into a reaction kettle, place it in a vacuum oven and heat at 220° C. for 24 hours.

[0042] 5. Repeatedly vacuum filter the reacted solution with deionized water until the solution becomes neutral.

[0043] 6. Finally, dry the obtained powder in the air at 60° C. for 36 hours to obtain a graphene-supported ceria nanocubic composite with (200) exposed surfaces.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com