Automobile exhaust gas emission and collection system of automobile assembly workshop

A technology for automobile assembly and automobile exhaust, applied in the direction of smoke and dust removal, cleaning methods and appliances, chemical instruments and methods, etc., can solve the problems of difficult maintenance, easy wear and tear of exhaust hose, heavy use, etc., to achieve flexible operation and solve problems The effects of automobile exhaust pollution and simple and convenient maneuvering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

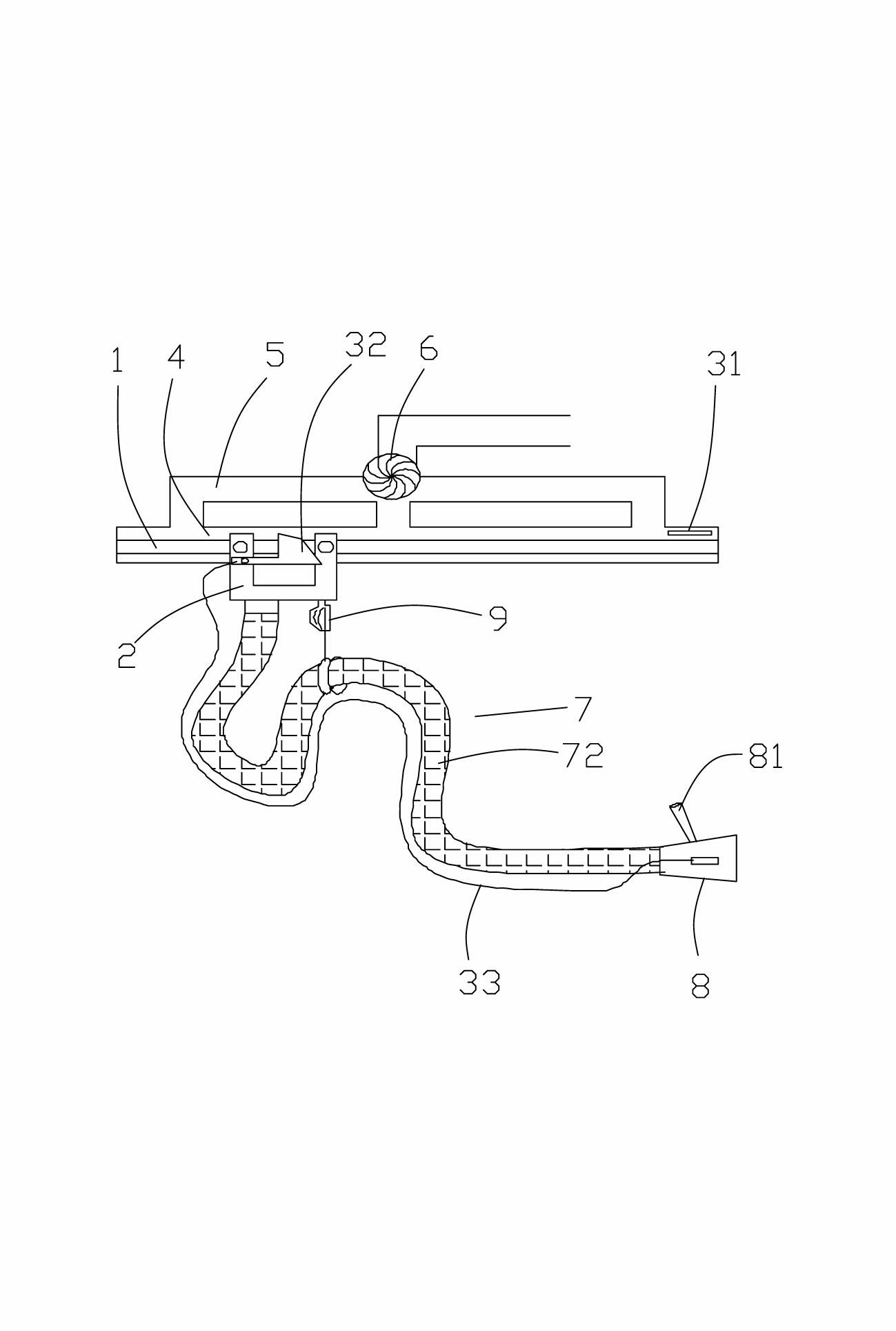

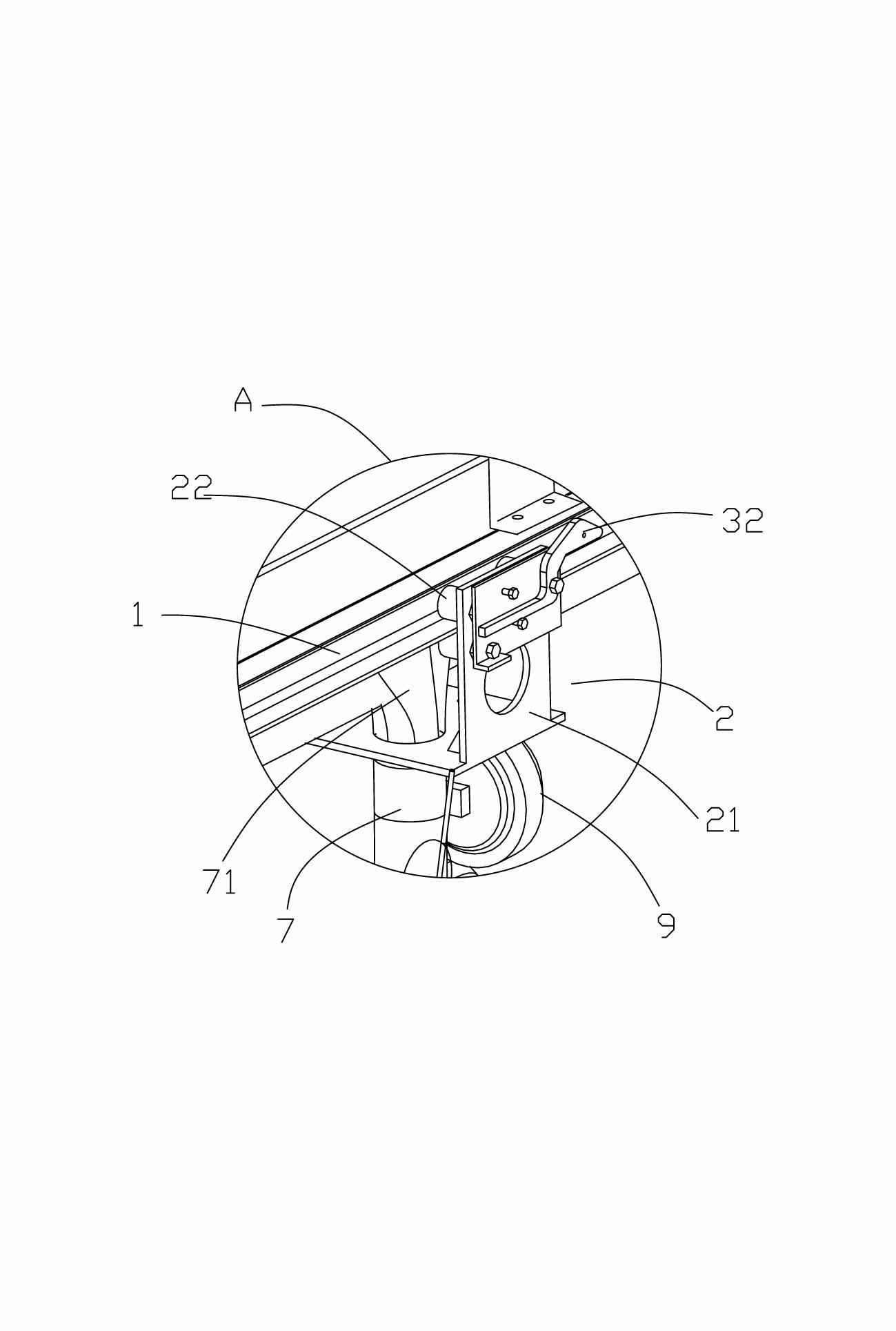

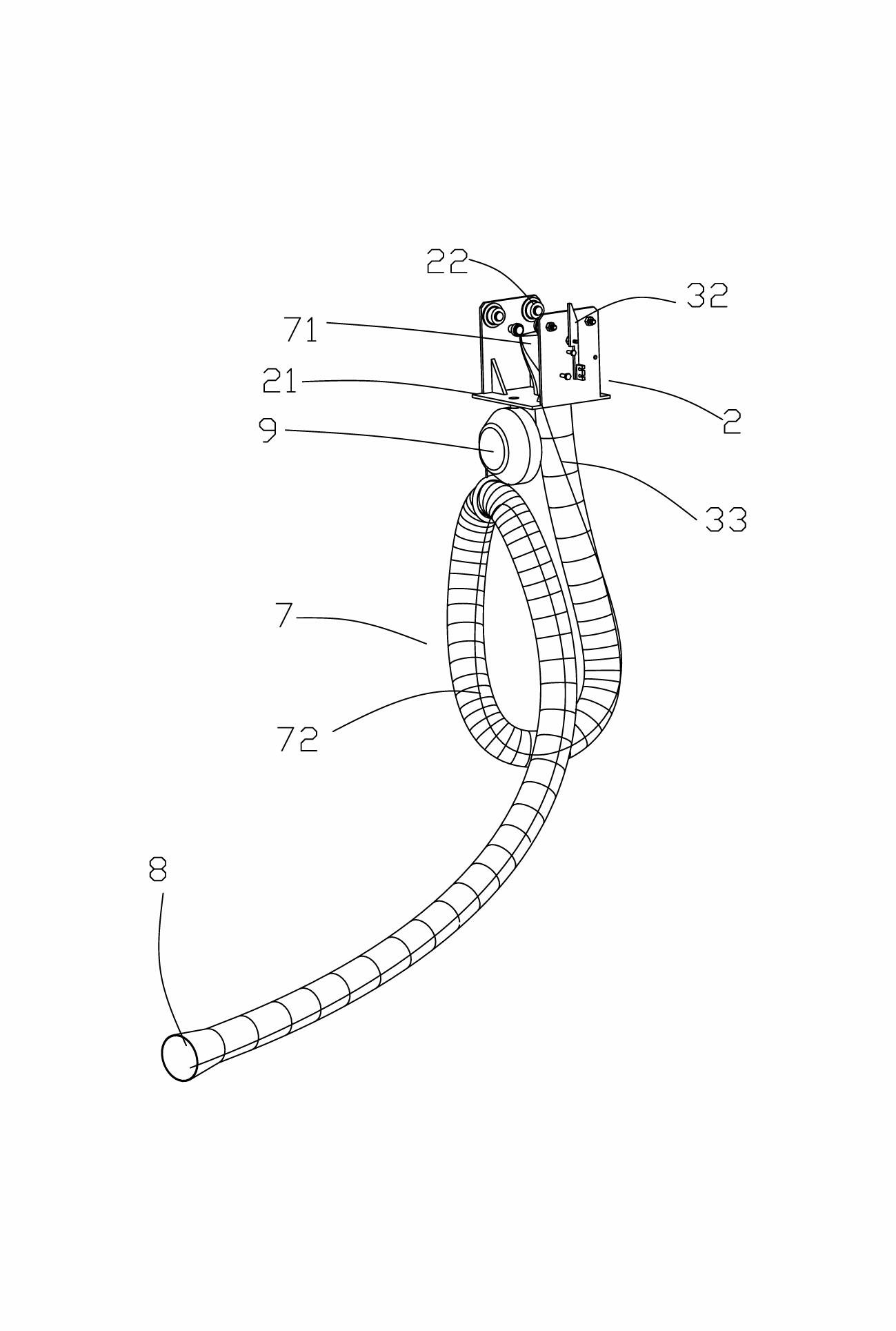

[0023] refer to Figure 1 to Figure 6 , an automobile exhaust emission collection system in an automobile assembly workshop provided by the present invention includes a circular track 1 and a slidable trolley 2 installed on the track 1, the track 1 is divided into a working area 11 and a non-working area 12, The working area 11 of the track 1 is provided with an exhaust duct 4, and the exhaust duct 4 is connected with the exhaust fan 6 through a pipeline 5. An exhaust hose 7 is arranged on the sliding trolley 2, and one end of the exhaust hose 7 is connected to the exhaust duct. 4 connection, the other end is connected with the automobile exhaust pipe through the exhaust joint 8.

[0024] As a preferred embodiment, the track 1 is composed of two guide rails 13 forming a "] [" shape, and the sliding trolley 2 is composed of a trolley frame 21 and rollers 22 and rolling elements installed on both sides of the trolley frame 21, The rollers 22 are hooked on the guide rail 13 . I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com