Pneumatic conveying and blast furnace injecting device for coke oven dust-removing ash and using method thereof

A coke oven dust removal and pneumatic conveying technology, applied in the metallurgical field, can solve the problems of consuming new water for humidity adjustment and high transportation costs, and achieve the effect of reducing the labor intensity of employees and realizing the concept of production and operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

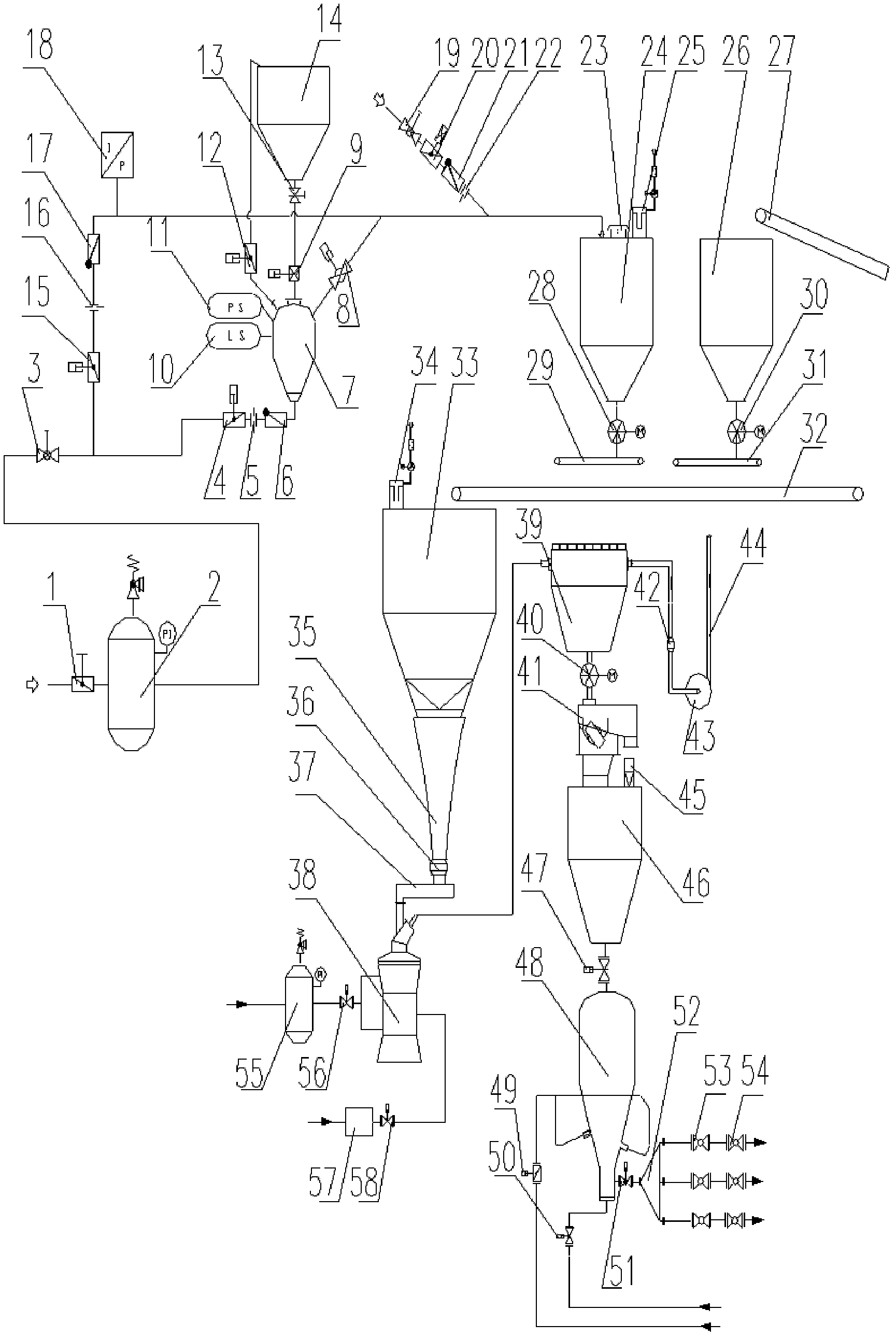

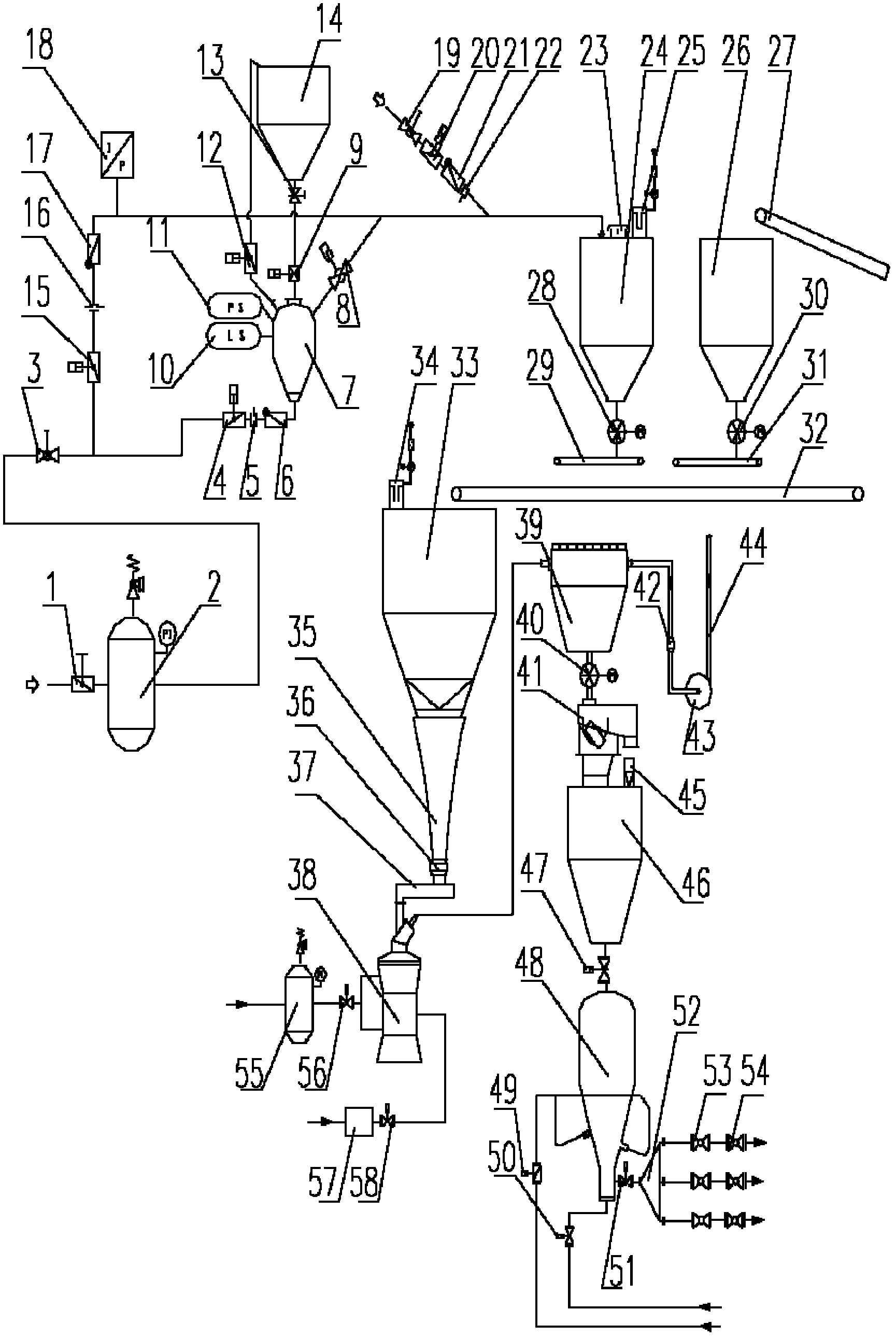

[0036] Depend on figure 1 As can be seen from the structure shown, this kind of pneumatic conveying and blast furnace injection device for coke oven dedusting includes coke oven dedusting pneumatic conveying air source unit, coke oven dedusting main unit, air pressure balance unit, ash conveying pipeline along the Blockage cleaning unit, coke oven dust removal and washed coal distribution unit, coke oven dust removal and washed coal grinding unit, coke oven dust removal and washed coal grinding material collection unit, pulverized coal drying unit, coke oven dust removal Ash and washed coal grinding process safety fire extinguishing unit and blast furnace injection unit, the above units are connected through the corresponding pipeline system; coke oven dust removal ash pneumatic conveying gas source unit is connected in turn through the corresponding pipeline system first manual valve 1, Composed of compressed air drum 2 and second manual valve 3; the pipeline coming out of se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com