Composite material with formaldehyde purification function and production method thereof

A composite material and functional technology, applied in the fields of building materials, chemical industry, and light industry, can solve the problems of long absorption and conversion cycle, discontinuous degradation, inconvenient use, etc., and achieve a significant purification effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

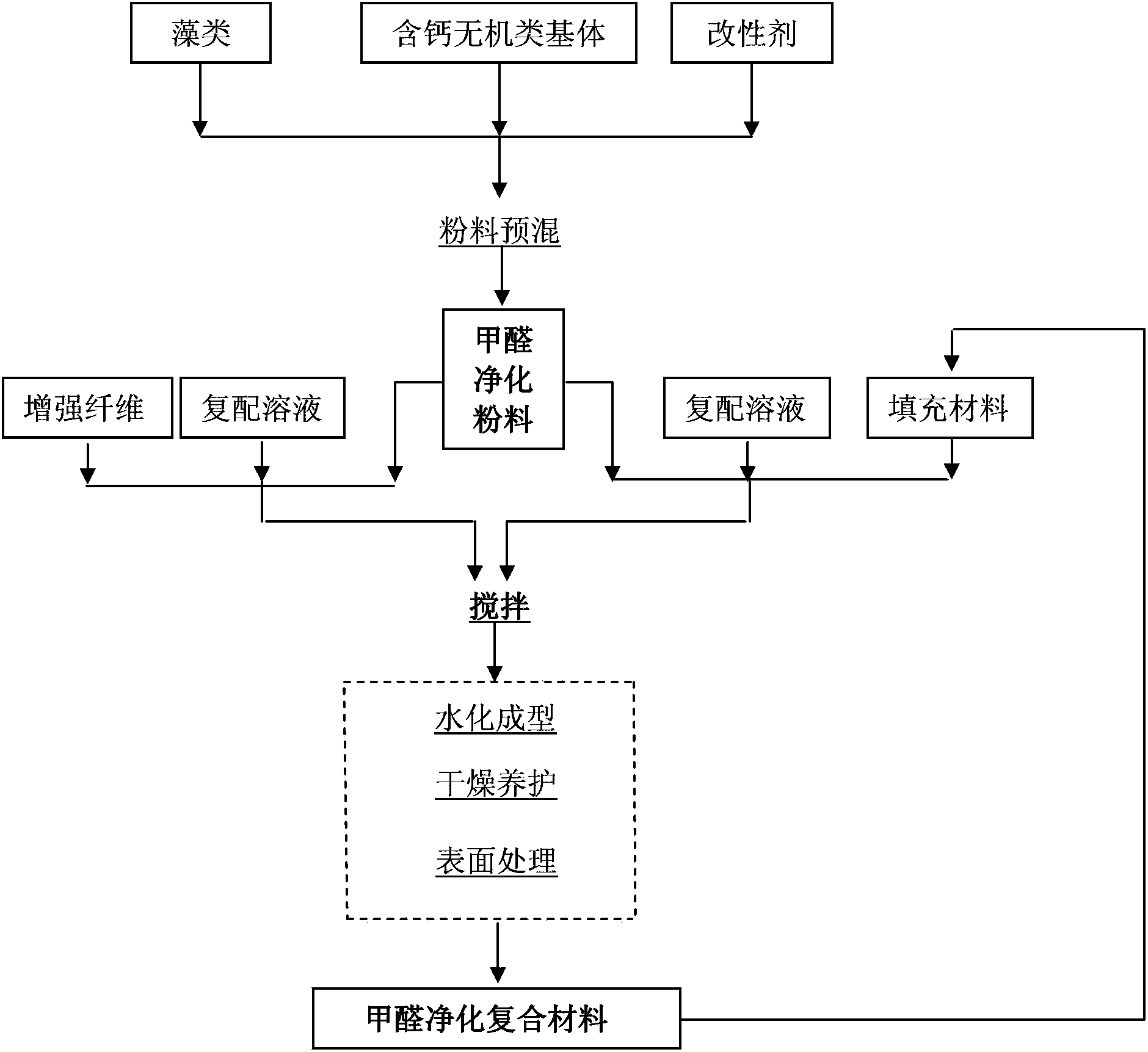

Method used

Image

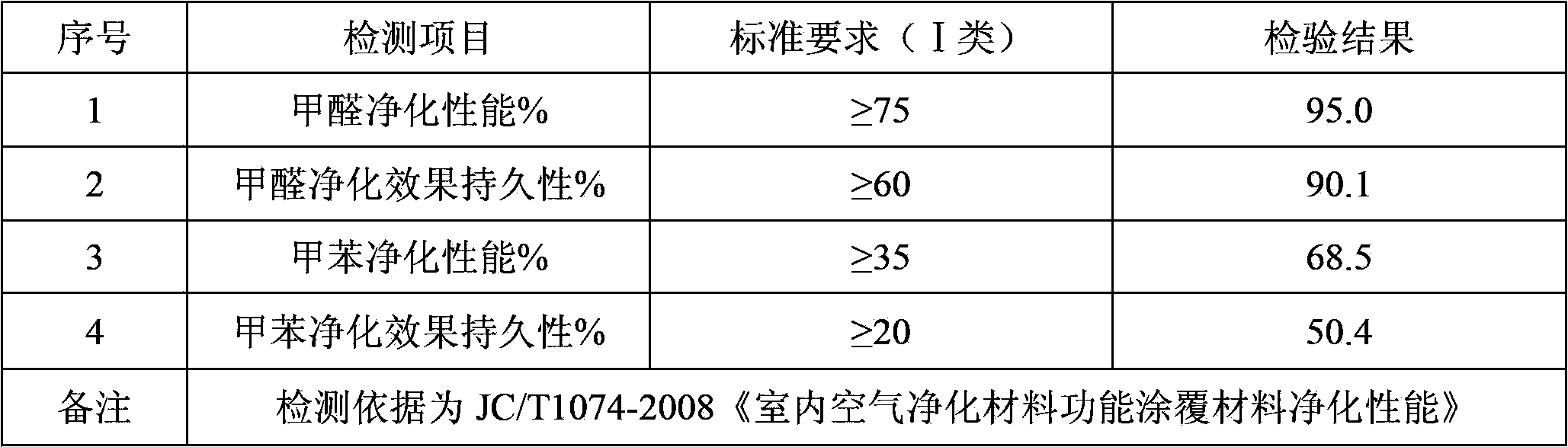

Examples

Embodiment 1

[0046] 实施例1:一种具有甲醛净化功能的粉料

[0047] 1、配方组成(物质计量单位均为重量份):

[0048] (1)天然β-半水硫酸钙48.8份;

[0049] (2)硅藻土:粒度400~800目经粉磨的硅藻土粉体10份;

[0050] (3)改性剂:由54%氧化钙、36%氧化硅、10%聚乙烯醇混合均匀复配粉体6份;

[0051] 2、生产制备工艺:

[0052] (1)原材料预处理:β-半水硫酸钙、硅藻土、改性剂按41份、12份、4份、2份分别精确计量;

[0053] (2)预混合后在陈化仓中陈化3~15天制备即得。

Embodiment 2

[0054] 实施例2:一种具有甲醛净化功能的仿木板

[0055] 1、配方组成(物质计量单位均为重量份):

[0056] (1)天然磷酸钙54.8份;

[0057] (2)硅藻土:粒度400~800目经粉磨的硅藻土粉体16份;

[0058] (3)改性剂:由54%氧化钙、36%氧化硅、10%聚乙烯醇混合均匀复配粉体6份;

[0059] (4)增强纤维短切丝:长度在15~18mm植物纤维1.20份;

[0060] (5)复配溶液:清水、转晶剂、防水剂、消泡剂按其质量比为100∶1.8∶0.4∶0.5复配搅拌形成均匀的复配溶液22份。所述的转晶剂为柠檬酸钠;所述的防水剂是甲基硅醇钠;所述的消泡剂是磷酸三丁酯。

[0061] 2、生产制备工艺:

[0062] (1)原材料预处理:磷酸钙、硅藻土、改性剂按54.8份、16份、6份分别精确计量、预混合后在陈化仓中陈化3~15天制备混合粉体;

[0063] (2)混合料搅拌:22份复配溶液单独准确计量后,再将其计量准确的混合粉体和1.2份植物纤维缓慢加入,待其液相介质充分浸润粉料后强制搅拌,搅拌转速为280~400转 / 分,搅拌时间为15~32秒;

[0064] (3)压制成型:将半湿半干状混合料借助压力设备及成型模具压制成型;

[0065] (4)养护干燥:脱模后自然放置2小时定型养护后采用自然干燥或者干燥窑烘干方式中的一种或两种,自然干燥3~5天,干燥窑干燥温度为50~65℃,干燥10~12小时,当含水重量小于3.5%时成为半成品;

[0066] (5)后处理:将干燥后的成型板材过干燥后打磨平整,采用涂料、烤漆、UV镀膜、丝印、烫金或其他材质贴面中的一种或多种表面处理方式,待其表面固化后形成一种具有甲醛净化功能仿木板材。

Embodiment 3

[0067] 实施例3:一种具有甲醛净化功能的颗粒状复合材料

[0068] 1、配方组成(物质计量单位均为重量份):

[0069] (1)天然铝酸钙54.8份;

[0070] (2)海藻土:粒度400~800目经粉磨的海藻土粉体10份;

[0071] (3)改性剂:由54%氧化钙、36%氧化硅、10%聚乙烯醇混合均匀复配粉体3份;

[0072] (4)增强纤维短切丝:长度在15~18mm植物纤维0.8份。

[0073] 2、生产制备工艺:

[0074] (1)原材料预处理:按上述重量份将铝酸钙、海藻土、改性剂分别精确计量、预混合后在陈化仓中陈化3~15天制备混合粉体;

[0075] (2)混合料搅拌:按上述重量份将其计量准确的混合粉体和植物纤维混合均匀;

[0076] (3)压制成型:将步骤(2)搅拌均匀的混合料通过定型颗粒挤出机挤出成型获得不同形状的颗粒状;再经过常规后处理得到颗粒状材料。

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com