Polymethylene-based star polymer, preparation method and application of polymethylene-based star polymer

A star-shaped polymer, polymethylene technology, applied in the field of polyolefin functionalization, can solve the problem of not much research on synthesis and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 19

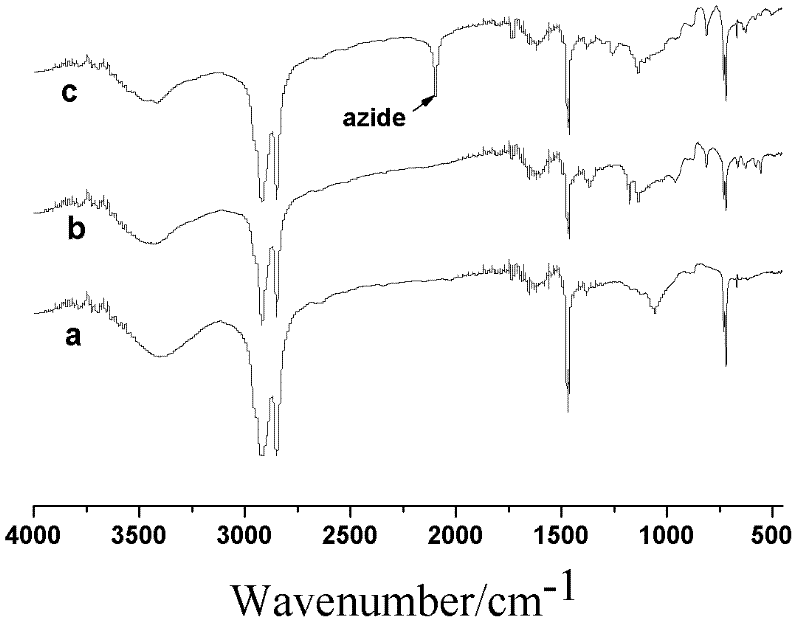

[0098] The specimens in Example 19 were prepared with a micro injection molding machine (ISO527-2-A5a tensile test mold). Scanning electron microscope pictures were observed and measured on a scanning electron microscope (JSM-6390LV). The infrared spectrograms of the samples in the examples were obtained by testing on Nicolet AVATAR-360 using potassium bromide pellets.

[0099] The bromine content of the polymer was tested by ion chromatography.

Embodiment 1

[0101] The preparation of star polymethylene of the present invention:

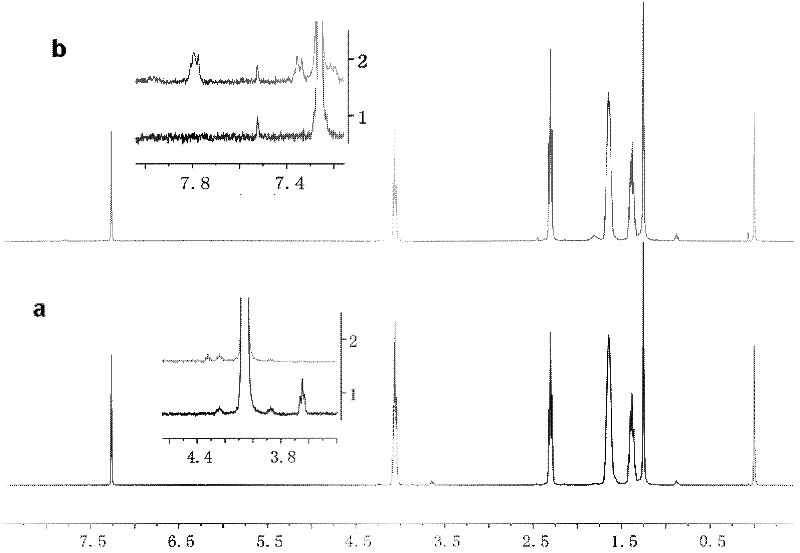

[0102] In a dry 150mL round bottom flask with a magnetic stir bar, add 0.50g (0.25mmol) PM under nitrogen protection 2K -OH (K=1000g / mol, the same below. 1 H NMR (500MHz, D 4 -o-dichlorobenzene, 80°C, δppm): 3.60 (t, 2H), 1.55 (t, 2H), 1.20-1.46 (m, 280H), 0.91-0.94 (m, 12H). m n =1800g / mol, PDI=1.09), after vacuuming for 10min, fill with nitrogen. Add 75mL of dry toluene (refluxing with sodium metal), stir at 90°C for 0.5h to dissolve completely, and quickly add 2.5mol / L n-butyllithium n-hexane solution (0.11mL, 0.27mmol) after cooling down to room temperature, and stir After 30min, a toluene solution of p-toluenesulfonyl chloride (0.60mmol, 0.114mg, 10mL) was added, and refluxed overnight. After the reaction, it was directly precipitated in methanol, and the filtered solid was dissolved in toluene and methanol precipitated twice to obtain 0.52g (97% )PM 2K -OTs.

[0103] 0.127g (1.95mmol) NaN 3 ...

Embodiment 2

[0110] The preparation of star polymethylene of the present invention:

[0111] In a dry 150mL round bottom flask with a magnetic stir bar, add the macroinitiator PM under nitrogen protection 2K COC(CH 3 ) 2 -Br 0.20g (0.11mmol Br, M n = 1860 g / mol, PDI = 1.23, bromine content = 0.54 μmol / g polymer. 1 H NMR (500MHz, δppm): 3.92(t, 2H), 1.69(s, 6H), 1.42(t, 2H), 1.10(m, 240H), 0.67(s, 12H)) and 0.072g (1.1mmol) NaN 3 , then add 50mL of toluene and 25mL of DMF, reflux for 24h, precipitate in a mixed solvent of methanol and water (90:10, v / v), filter and wash the filter cake with water and acetone three times, and vacuum dry at 50°C for 24h to obtain 0.18g (92% yield) PM 2K COC(CH 3 ) 2 -N 3 .

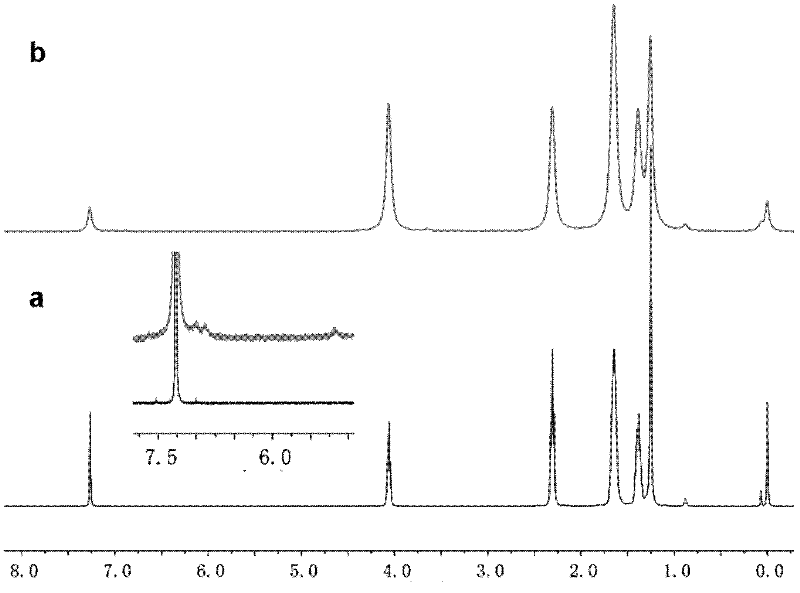

[0112] In another 10mL dry round bottom flask B with a magnetic stir bar, add 0.15g (0.108mmol) PM under nitrogen protection 2K COC(CH 3 ) 2 -N 3 , 7.7mg (0.054mmol) CuBr, 0.15g (0.108mmol) T' 2 , 22.5μL (0.108mmol) PMDETA (N, N, N', N', N"-pentamethyldivinyltriamine) and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com