Preparation method of water-soluble CdTe quantum dot

A quantum dot, water-soluble technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of cumbersome operation, limited greening and flexibility, harsh organic phase synthesis conditions, etc., to achieve high quantum yield, easy to implement , a small number of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Dilute 1.24 ml of 80.7 mmol / L cadmium dichloride to 88.76 ml with distilled water at room temperature, and add 21.34 ul of MPA;

[0040] (2) Add 8.0 mg TeO to the solution in step (1) 2 , and then use sodium hydroxide to adjust the pH of the solution to 11.5;

[0041] (3) Nitrogen was passed to the solution of step (2) for 5 to 30 minutes, under stirring, 5.8 mg of sodium borohydride was added, and then 5 milliliters of distilled water was added to make sodium borohydride completely enter the solution;

[0042] (4) Heating the solution in step 3 to 100° C.; taking samples at regular intervals to monitor the progress of the reaction;

[0043] (5) Centrifuge the solution obtained in step (4) at a speed of 8000 rpm, remove the supernatant and disperse the precipitate in the acetone solution, centrifuge for 2 to 4 times, and finally dissolve the precipitate in water. Water-soluble CdTe quantum dots were obtained.

[0044] The molar ratio of raw materials in this exam...

Embodiment 2

[0047] The consumption of preparation step and cadmium dichloride is identical with embodiment 1, and raw material molar ratio is CdCl 2 :MPA:TeO 2 =1:1.3:0.5.

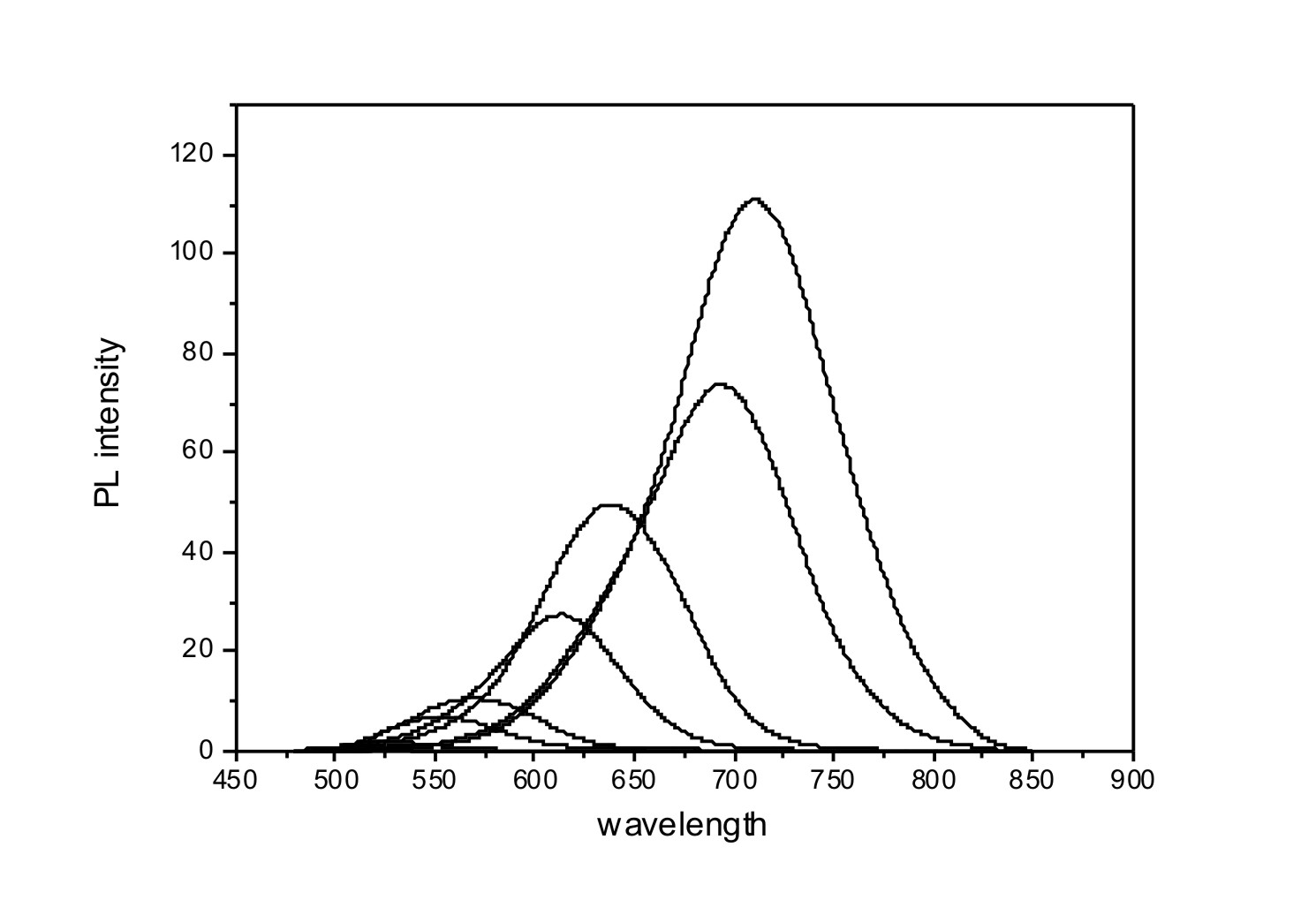

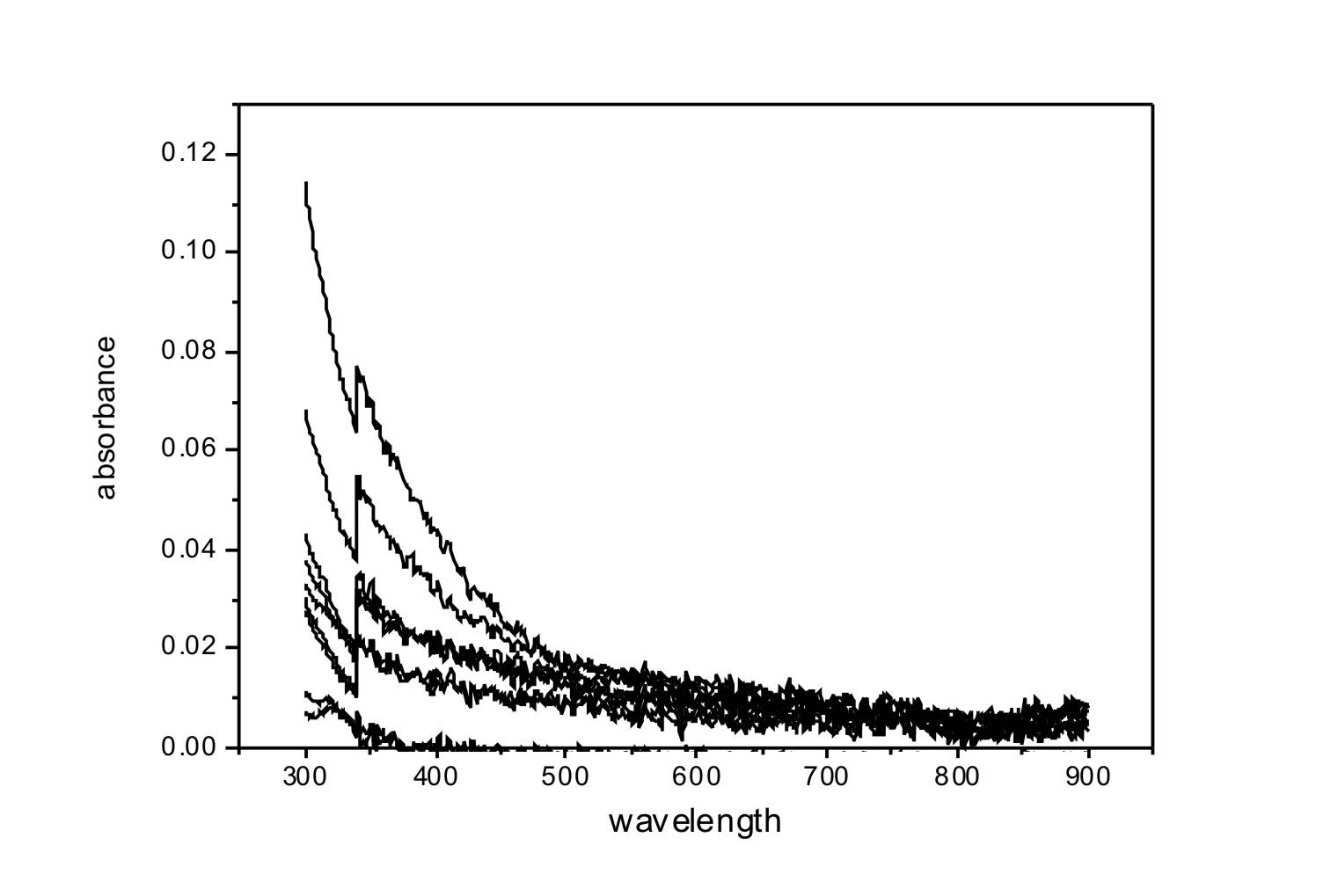

[0048] image 3 , Figure 4It is the fluorescence spectrogram and the ultraviolet-visible light absorption spectrogram of the water-soluble CdTe quantum dot obtained in Example 2.

Embodiment 3

[0050] The consumption of preparation steps and cadmium dichloride is identical with embodiment 1, and raw material molar ratio is CdCl 2 :MPA:TeO 2 =1:1.3:0.2.

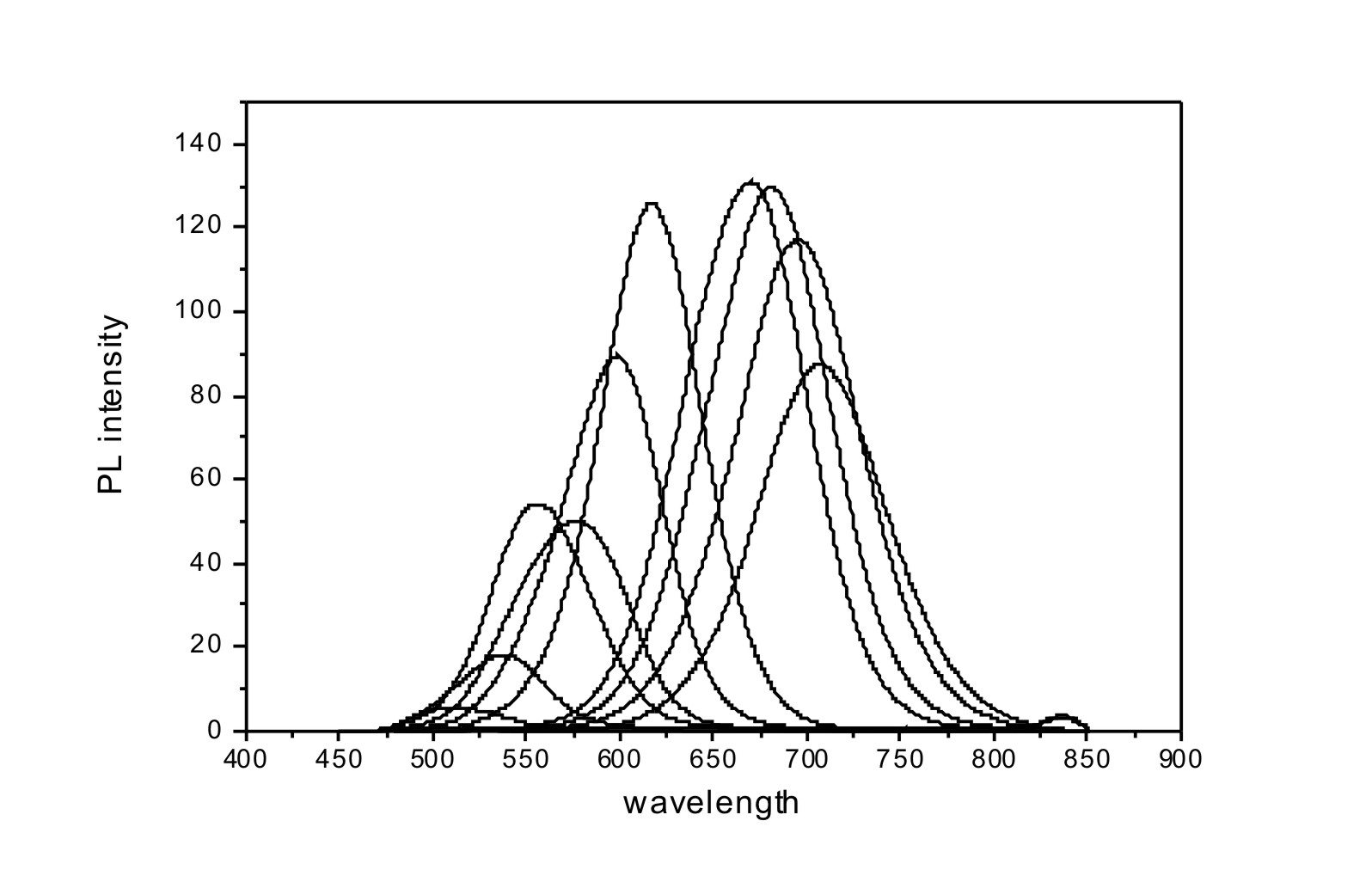

[0051] Figure 5 , Image 6 It is the fluorescence spectrogram and the ultraviolet-visible light absorption spectrogram of the water-soluble CdTe quantum dot obtained in Example 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com