Novel total-synthesis water-soluble magnesium alloy cutting solution and preparation method thereof

A water-soluble magnesium, fully synthetic technology, used in lubricating compositions, petroleum industry, etc., can solve the problems of threatening the personal safety of operators, shortening the service life of cutting fluids, increasing production costs, etc., to improve safety and reduce overall costs. , the effect of improving lubricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

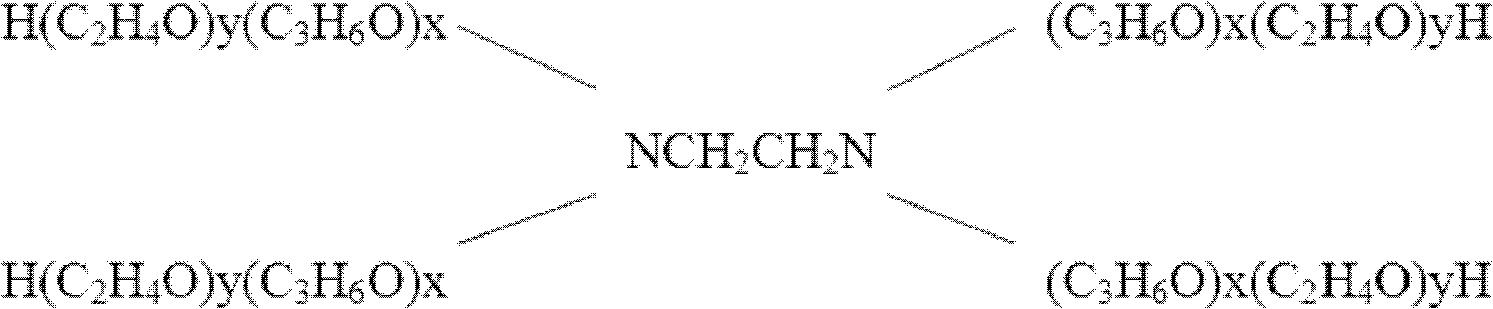

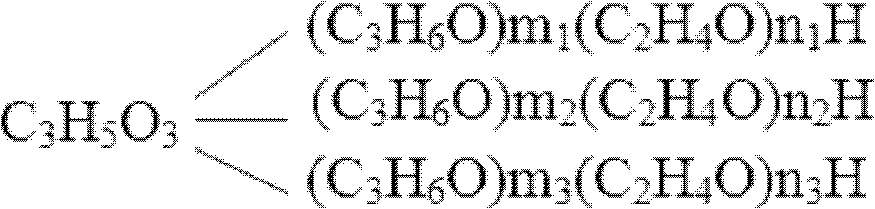

Method used

Image

Examples

preparation example Construction

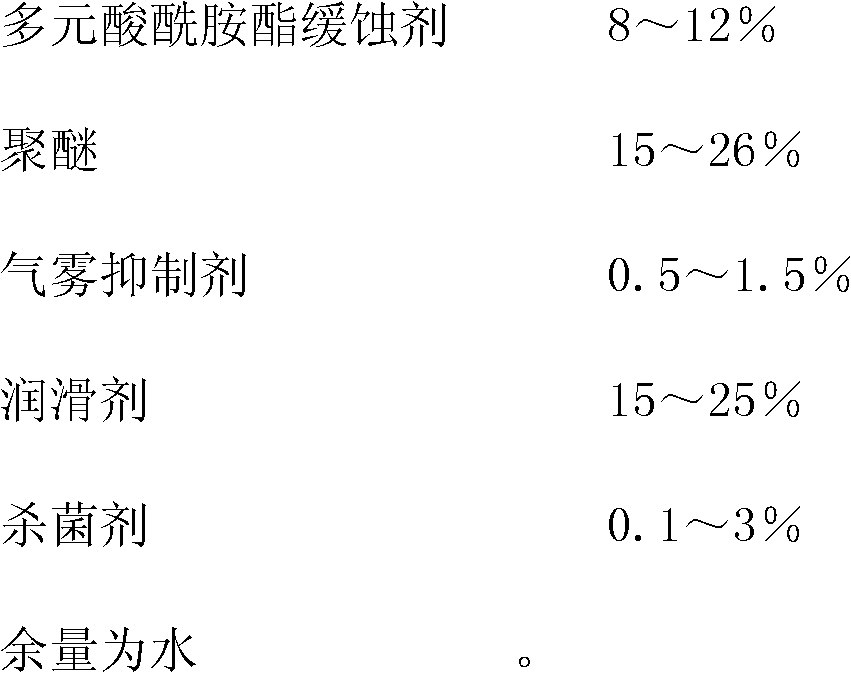

[0081] The preparation method of above-mentioned novel fully synthetic water-soluble magnesium alloy cutting fluid comprises the following steps:

[0082] (1) Warm up the water to 40-50°C, add polybasic acid amide ester corrosion inhibitor, polyether and lubricant while stirring;

[0083] (2) While stirring, add an aerosol inhibitor and a bactericide to the liquid obtained in step (1), and keep warm during the addition;

[0084] (3) cooling the liquid obtained in step (2) to room temperature to obtain the finished product.

Embodiment 1

[0086]

[0087]

[0088] The above components are mixed according to the following steps:

[0089] (1) Deionized water is heated up to 40°C, and polybasic acid amide ester corrosion inhibitor, polyether and lubricant are added while stirring;

[0090] (2) While stirring, add an aerosol inhibitor and a bactericide to the liquid obtained in step (1), and keep warm during the addition;

[0091] (3) cooling the liquid obtained in step (2) to room temperature to obtain the finished product.

Embodiment 2

[0093]

[0094]

[0095] The above components are mixed according to the following steps:

[0096] (1) Deionized water is heated up to 50°C, and polybasic acid amide ester corrosion inhibitor, polyether and lubricant are added while stirring;

[0097] (2) While stirring, add an aerosol inhibitor and a bactericide to the liquid obtained in step (1), and keep warm during the addition;

[0098] (3) cooling the liquid obtained in step (2) to room temperature to obtain the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com