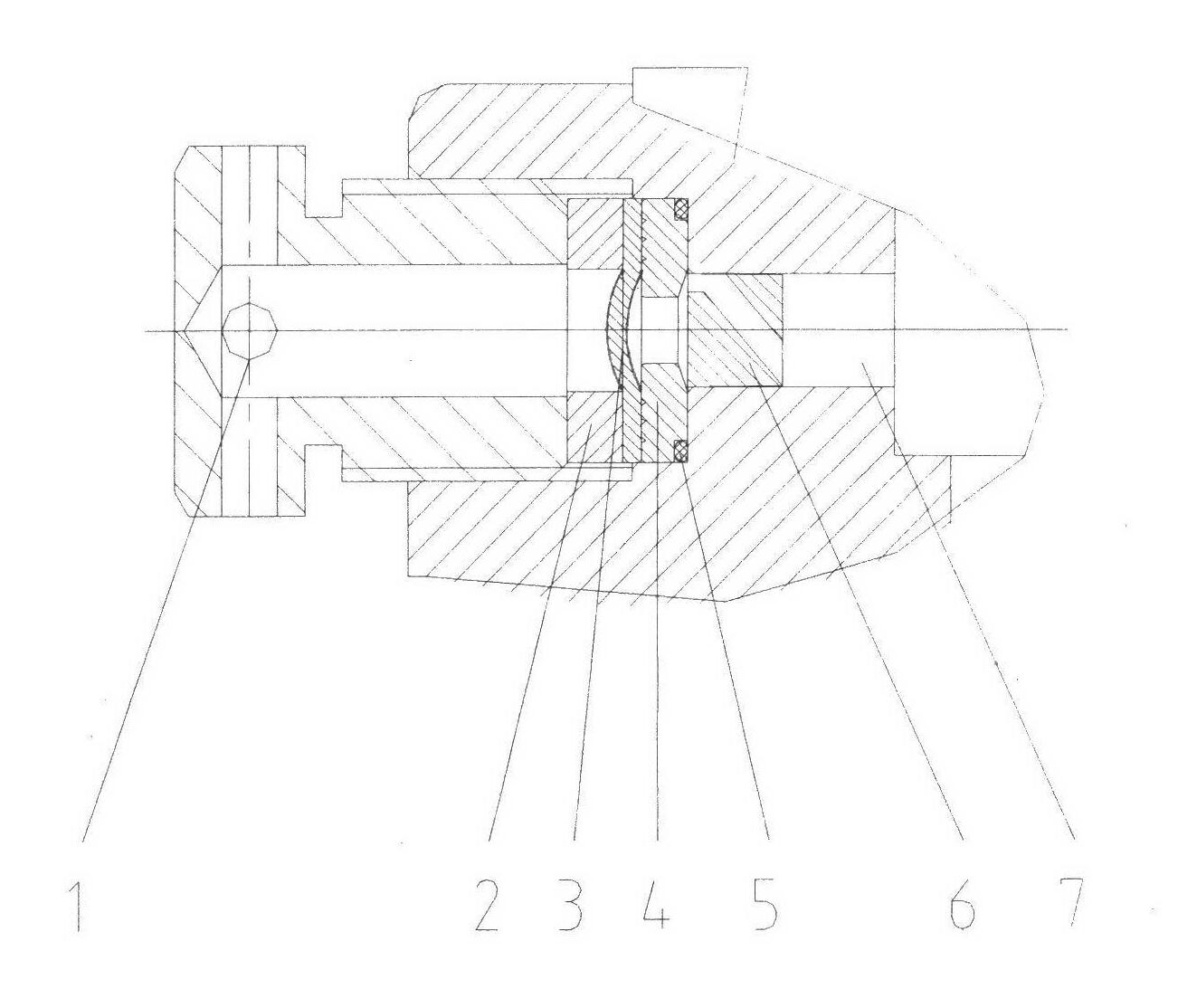

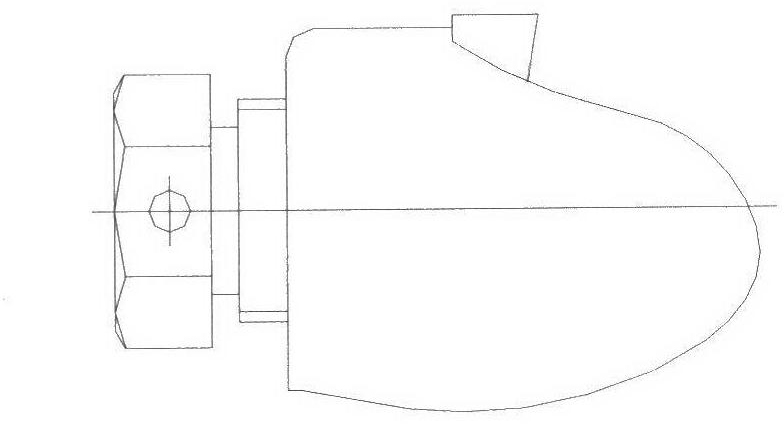

Safe discharging mechanism

A safe venting and venting technology, used in the field of fire fighting and fire control, can solve the problems of assembly and rotation wrinkle leakage, poor corrosion resistance, blasting and venting, etc., to avoid wrinkling and enhance environmental adaptability. , The effect of improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

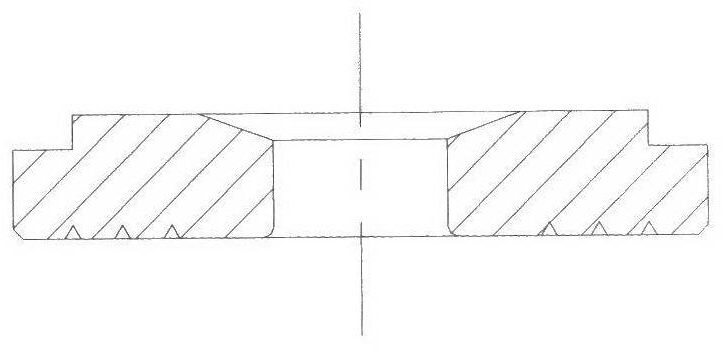

[0020] The safety relief mechanism is composed of: body, diaphragm, relief screw plug, pressure ring, gasket, O-ring, and damping plug. The diaphragm is sandwiched between the pressure ring and the gasket, and the contact surface is lubricated with Vaseline. The discharge screw plug is fastened to the pressure relief port of the body through a constant torque wrench. The damping plug is fitted in the pressure relief port of the body with an O-shaped seal. The ring is embedded in the gasket groove; it is usually in a pressure-sealed state. The gasket inlet adopts O-shaped sealing rings and several grooves are processed on the outlet plane. Under the long-term storage servo working state, it maintains a reliable seal when it experiences temperature cycles and vibrations; When the pressure is released, the overpressure pressure source forms a narrow oblique flow and direct flow through the damping plug, and turns to the tapered surface of the gasket and enters the cylindrical hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com