Heat pump regeneration rotating wheel type total heat recovery humidity-adjusting and temperature-controlling fresh air handling unit and control method thereof

A technology of total heat recovery and fresh air units, applied in heat recovery systems, heating and ventilation control systems, heating methods, etc., can solve the problems of irreversible loss, low heat energy utilization efficiency, etc., to reduce energy consumption and improve indoor air quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

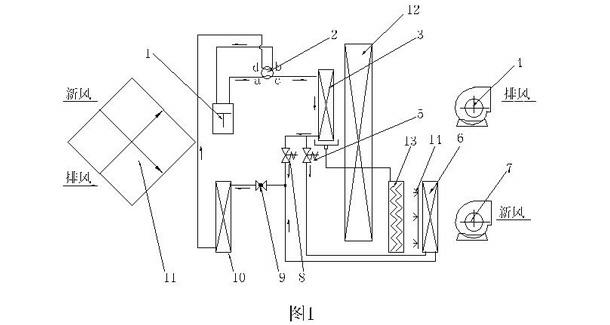

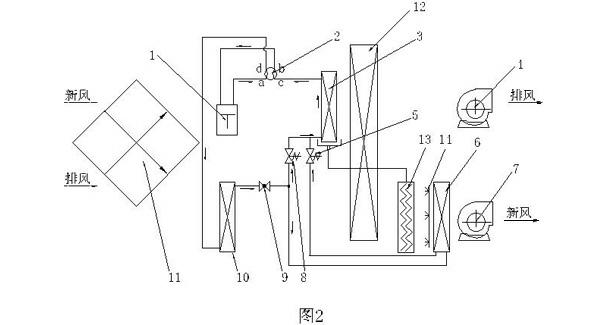

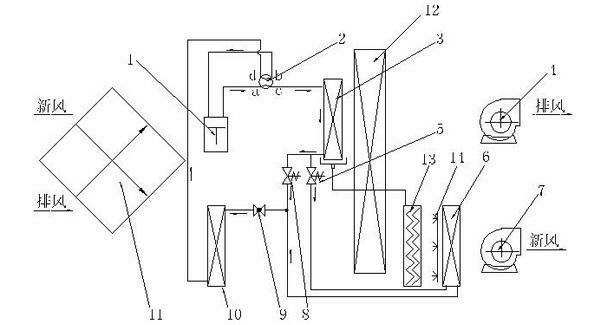

[0022] see figure 1 , The heat pump regenerative runner type total heat recovery humidity control temperature control fresh air unit and its control method are composed of an air-air heat recovery device, a dehumidification runner, an exhaust part, a fresh air processing part and a heat pump system. The number of dehumidification wheels is 12; the heat pump system includes a compressor 1, a four-way reversing valve 2, an evaporator 10, a condenser 3, a condensation heat recovery device 6 and a throttling component 9; the exhaust part is performed by the exhaust fan 4, and the fresh air is processed Partially performed by fresh air machine 7.

[0023] The dehumidification wheel 12 is at the next processing position where the air passes through the evaporator 10 and the condenser 3 of the heat pump system.

[0024] In the heat pump system, through the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com