Method for uninterrupted growth of high-quality InGaN/GaN multi-quantum well (MQW)

A multi-quantum well, high-quality technology, applied in the field of quantum well growth, can solve the problems of low time utilization rate and intermittent growth of quantum wells, and achieve the effect of shortening time and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

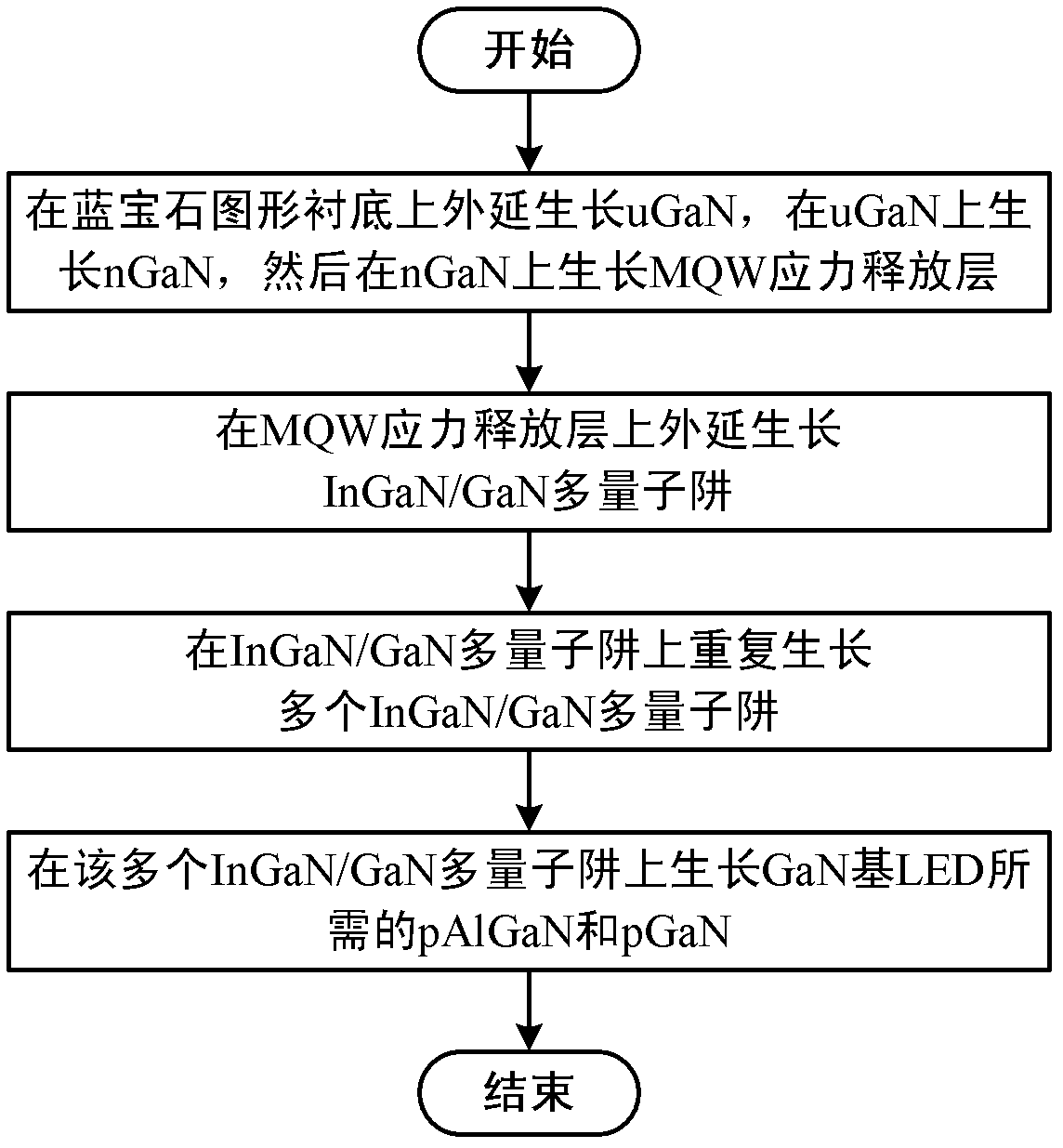

Method used

Image

Examples

Embodiment

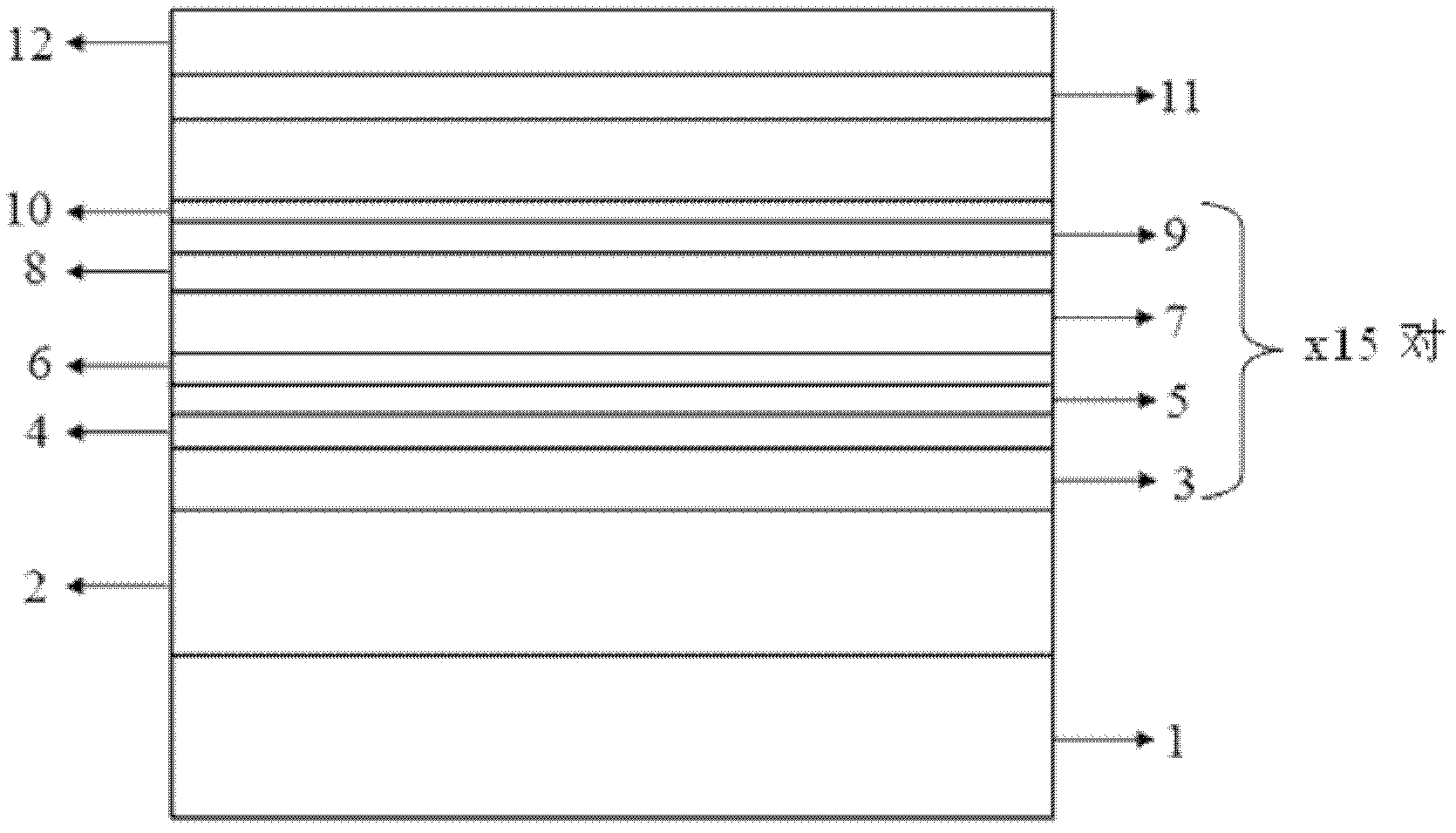

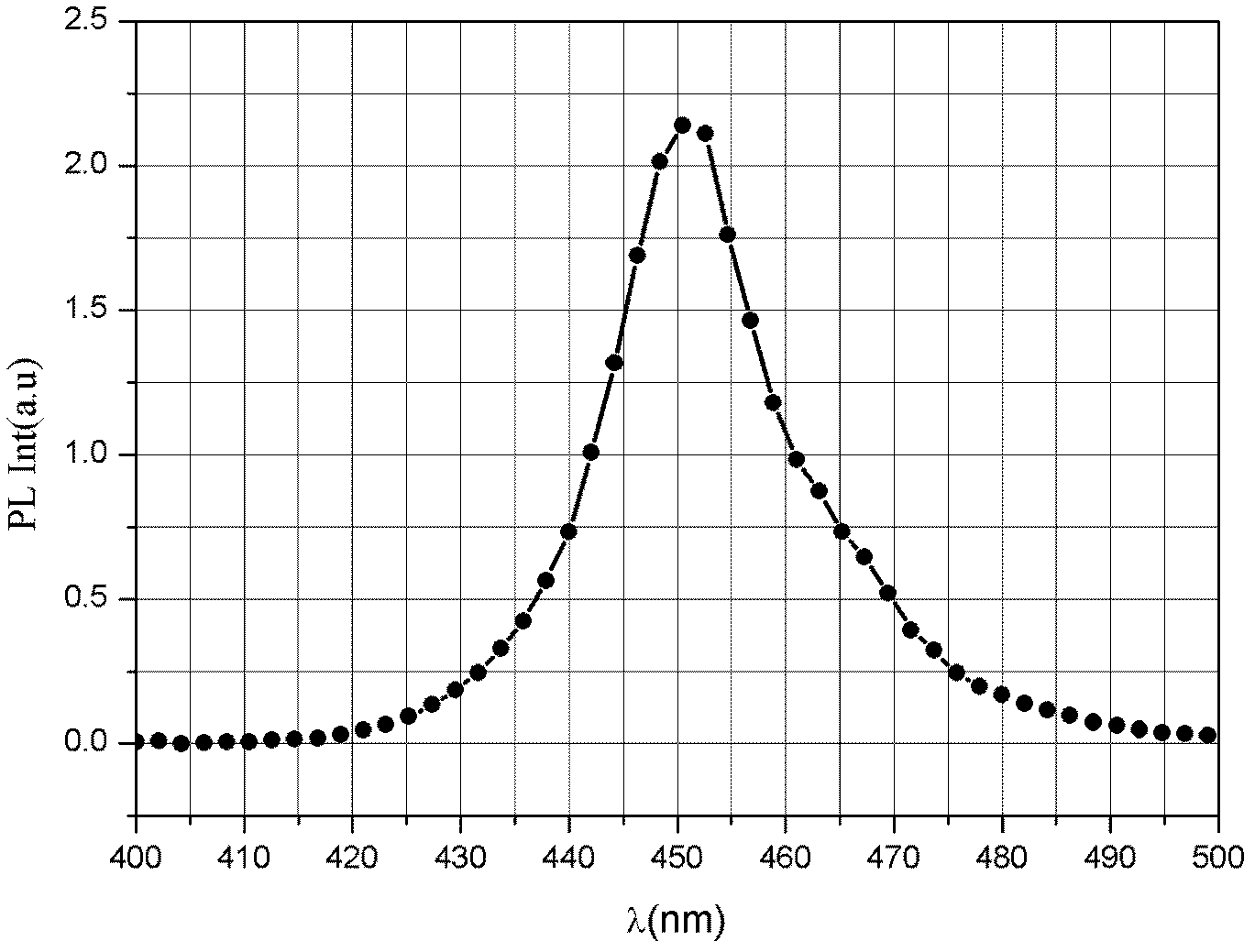

[0047] Utilize MOCVD equipment (Crius 31 commercial machine of Aixtron Company), select high-purity NH 3 As N source, high-purity N 2 and H 2 As carrier gas, trimethylindium (TMIn) and trimethylaluminum (TMAl) are used as indium source and aluminum source respectively, trimethylgallium (TMGa) is used as gallium source of GaN material, and triethylgallium (TEGa) is used as InGaN Ga source for GaN multiple quantum wells, silane (SiH 4 ) is an N-type dopant, and dicene Mg (Cp2Mg) is a P-type dopant. Epitaxially grow uGaN1 on the sapphire pattern substrate, then grow nGaN2 on uGaN1, and then grow MQW stress release layer 3 on nGaN2, the MQW stress release layer 3 adopts InGaN / GaN superlattice structure SLs, SLs logarithm is 4, the growth temperature is 900°C, and the thickness of InGaN in the InGaN / GaN superlattice structure SLs is The thickness of GaN is

[0048] Choose high-purity N 2 As the carrier gas, the InGaN quantum well 4 is epitaxially grown on the MQW stress re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com