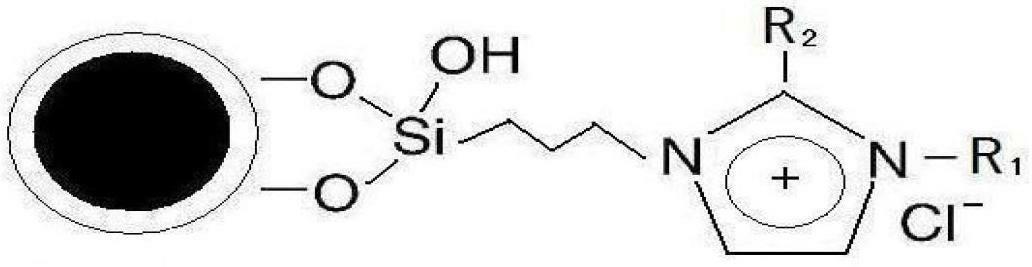

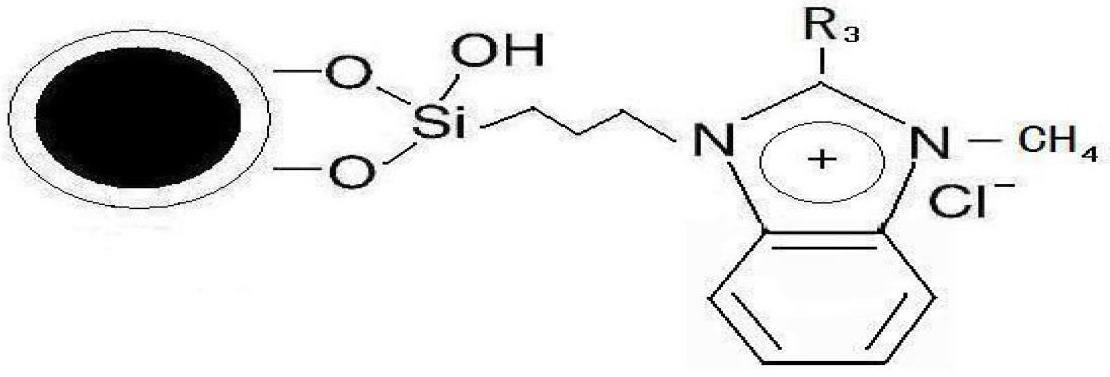

Ionic liquid functionalized magnetic nanoparticle and preparation method and application thereof

A technology of magnetic nanoparticles and ionic liquids, which is applied in peptide preparation methods, chemical instruments and methods, microsphere preparation, etc., to achieve good separation effect, simple and convenient operation, and short separation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

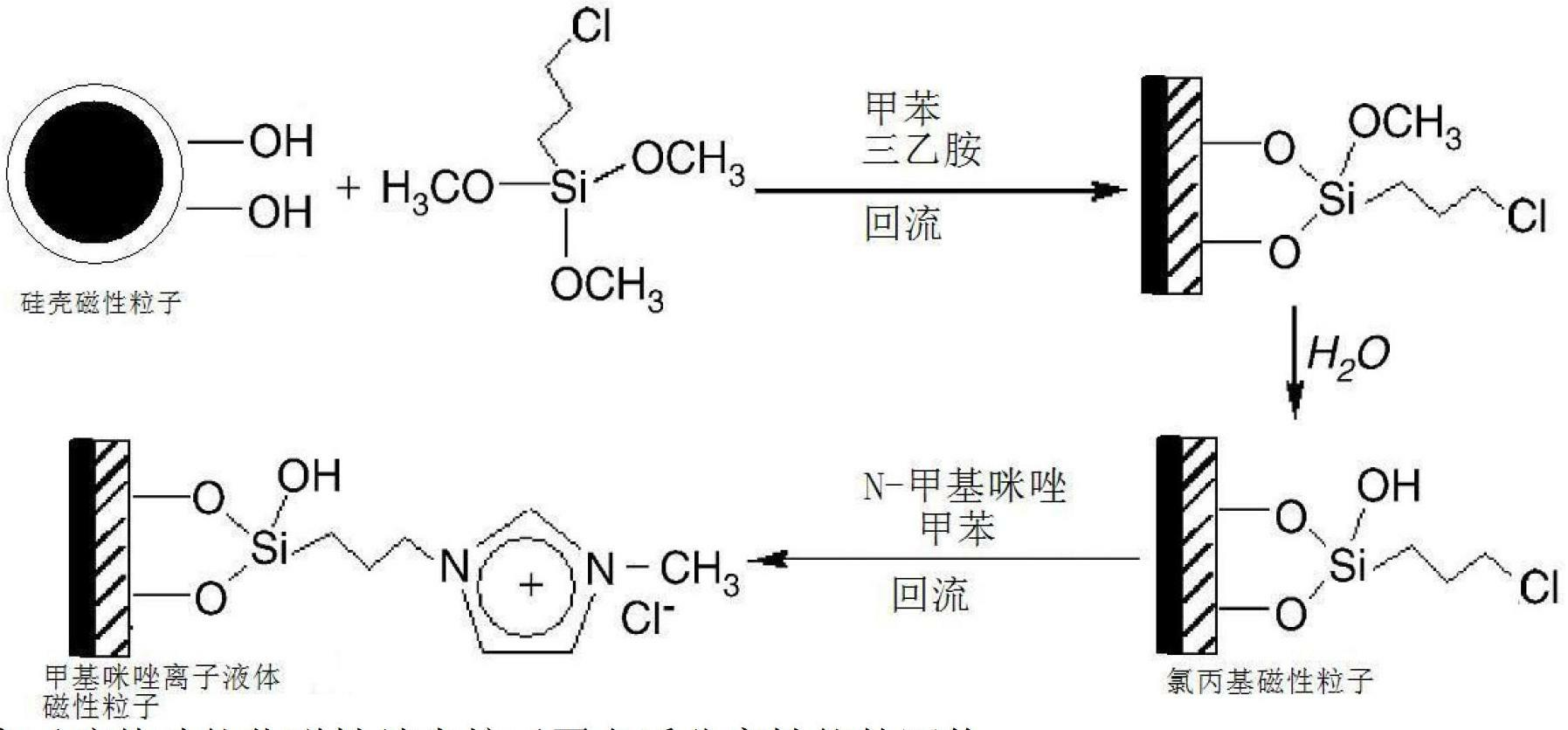

Method used

Image

Examples

Embodiment 1

[0032] (1) Fe 3 o 4 Preparation of Magnetic Nanoparticles

[0033] FeCl 3 .6H 2O1g, 2g of anhydrous sodium acetate dissolved in 40mL of ethylene glycol, put into a 50mL reactor and react at 200°C for 6h, after cooling, wash with ethanol and deionized water ultrasonically three times respectively, use an external magnetic field to separate, and finally use ethanol ultrasonically Preserve after dispersion to get Fe 3 o 4 magnetic nanoparticles.

[0034] (2) Fe 3 o 4 / SiO 2 Preparation of core-shell magnetic nanoparticles: weighing (1) product Fe 3 o 4 0.1g, add H 2 O and ethanol (EtOH), mixed at a volume ratio of 1 / 4, ultrasonically dispersed for 10 minutes, passed through N 2 , add NH under stirring 3 .H 2 O to adjust the pH to 9, add 0.1mL tetraethyl orthosilicate (TEOS) to the solution after heating up, and react at constant temperature for 1h, transfer the reaction mixture to a centrifuge tube for centrifugation, wash with deionized water and EtOH, and vacuum d...

Embodiment 2

[0041] (1) Fe 3 o 4 Preparation of Magnetic Nanoparticles: FeCl 3 .6H 2 O1g, 2g of anhydrous sodium acetate was dissolved in 40mL of ethylene glycol, put into a 50mL reactor and reacted at 200°C for 6h, after cooling, ultrasonically washed three times with ethanol and deionized water respectively, separated by an external magnetic field, and finally dispersed with ethanol ultrasonically After saving to get Fe 3 o 4 magnetic nanoparticles.

[0042] (2) Fe 3 o 4 / SiO 2 Preparation of core-shell magnetic nanoparticles: weighing (1) product Fe 3 o 4 0.1g, add H 2 O and ethanol (EtOH), mixed at a volume ratio of 1 / 4, ultrasonically dispersed for 10 minutes, passed through N 2 , add NH under stirring 3 .H 2 O to adjust the pH to 9, add 0.1mL tetraethyl orthosilicate (TEOS) to the solution after heating up, and react at constant temperature for 1h, transfer the reaction mixture to a centrifuge tube for centrifugation, wash with deionized water and EtOH, and vacuum dry at...

Embodiment 3

[0047] (1) Fe 3 o 4 Preparation of Magnetic Nanoparticles: FeCl 3 .6H 2 O1g, 2g of anhydrous sodium acetate was dissolved in 40mL of ethylene glycol, put into a 50mL reactor and reacted at 200°C for 6h, after cooling, ultrasonically washed three times with ethanol and deionized water respectively, separated by an external magnetic field, and finally dispersed with ethanol ultrasonically After saving to get Fe 3 o 4 magnetic nanoparticles.

[0048] (2) Fe 3 o 4 / SiO 2 Preparation of core-shell magnetic nanoparticles: weighing (1) product Fe 3 o 4 0.1g, add H 2 O and ethanol (EtOH), mixed at a volume ratio of 1 / 4, ultrasonically dispersed for 10 minutes, passed through N 2 , add NH under stirring 3 .H 2 O to adjust the pH to 9, add 0.1mL tetraethyl orthosilicate (TEOS) to the solution after heating up, and react at constant temperature for 1h, transfer the reaction mixture to a centrifuge tube for centrifugation, wash with deionized water and EtOH, and vacuum dry at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com