Rapid hydraulic press system used for hot-stamping forming of high-strength steel plate

A hot stamping forming, high-strength steel plate technology, applied in the field of hydraulic press system, can solve the problem that the main engine does not have fast clamping and punching, etc., and achieve the effect of shortening the pressing time, reducing the installed power and improving the work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

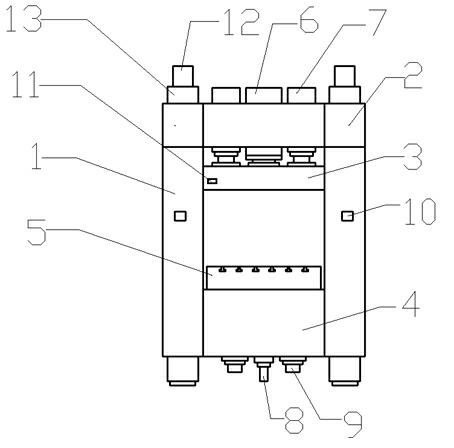

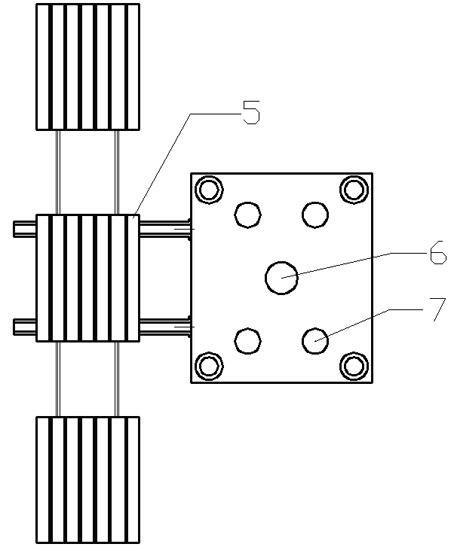

[0013] The fast hydraulic press system is mainly composed of main engine, lubrication system, hydraulic system, electrical control system and other auxiliary parts, protection system and so on. Wherein, the part other than the mainframe refers to and quotes the prior art, and will not be described in detail here. The main improvement part of the technology of the present invention revolves around the host part, and the following is combined with the attached figure 1 , 2 and the embodiment further illustrate the host part.

[0014] The main engine is a combined frame type tie rod pre-tightening structure, and the fuselage is a split frame structure, which is composed of an upper beam 2, a lower beam 4, a slider 3, a column 1, a tie rod 12, and a lock nut 13. The upper beam 2, the lower beam 4, and the column 1 of the main engine are tensioned by pull rods 12, and are pre-tightened and fixed with lock nuts 13 to form a closed force-bearing frame. The main oil cylinder 6 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com