Optical mirror ion beam nano-precision machining method based on combination of material addition and removal

A material addition, optical mirror technology, applied in the field of ion beam polishing, can solve the problems of increased processing time, inability to guarantee, difficult to remove low points of error, etc., to improve surface accuracy and surface roughness, improve surface shape Precision, the effect of maintaining optical surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

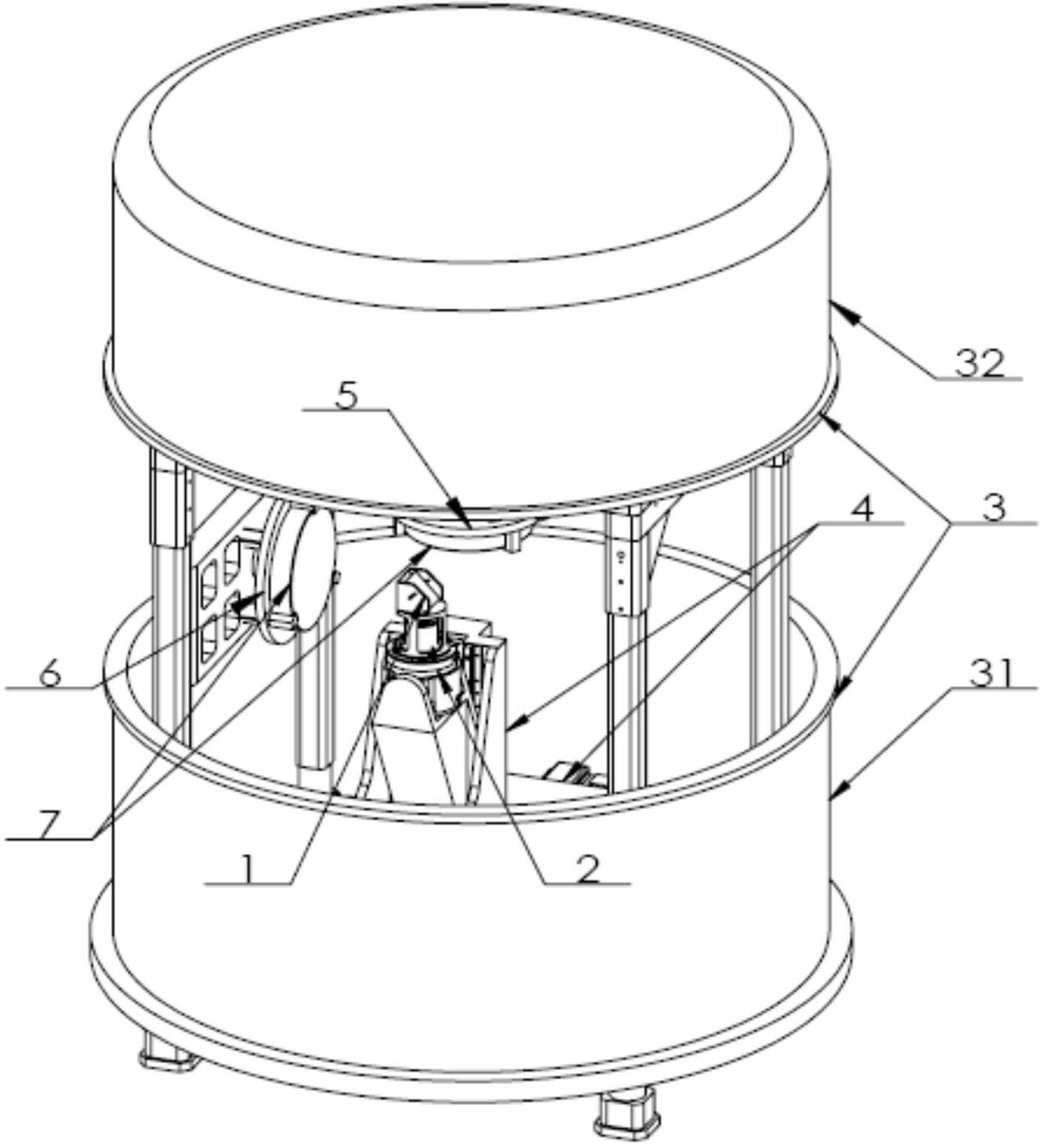

[0047] An ion beam nanometer-precision machining method based on the combination of material addition and removal according to the present invention. In this embodiment, the workpiece to be processed is a Φ100mm quartz plane (effective aperture is Φ90mm), and the initial surface shape error RMS value of the mirror surface is 110.2nm PV, 23.0nm RMS (see Figure 9 ), the process specifically includes the following steps.

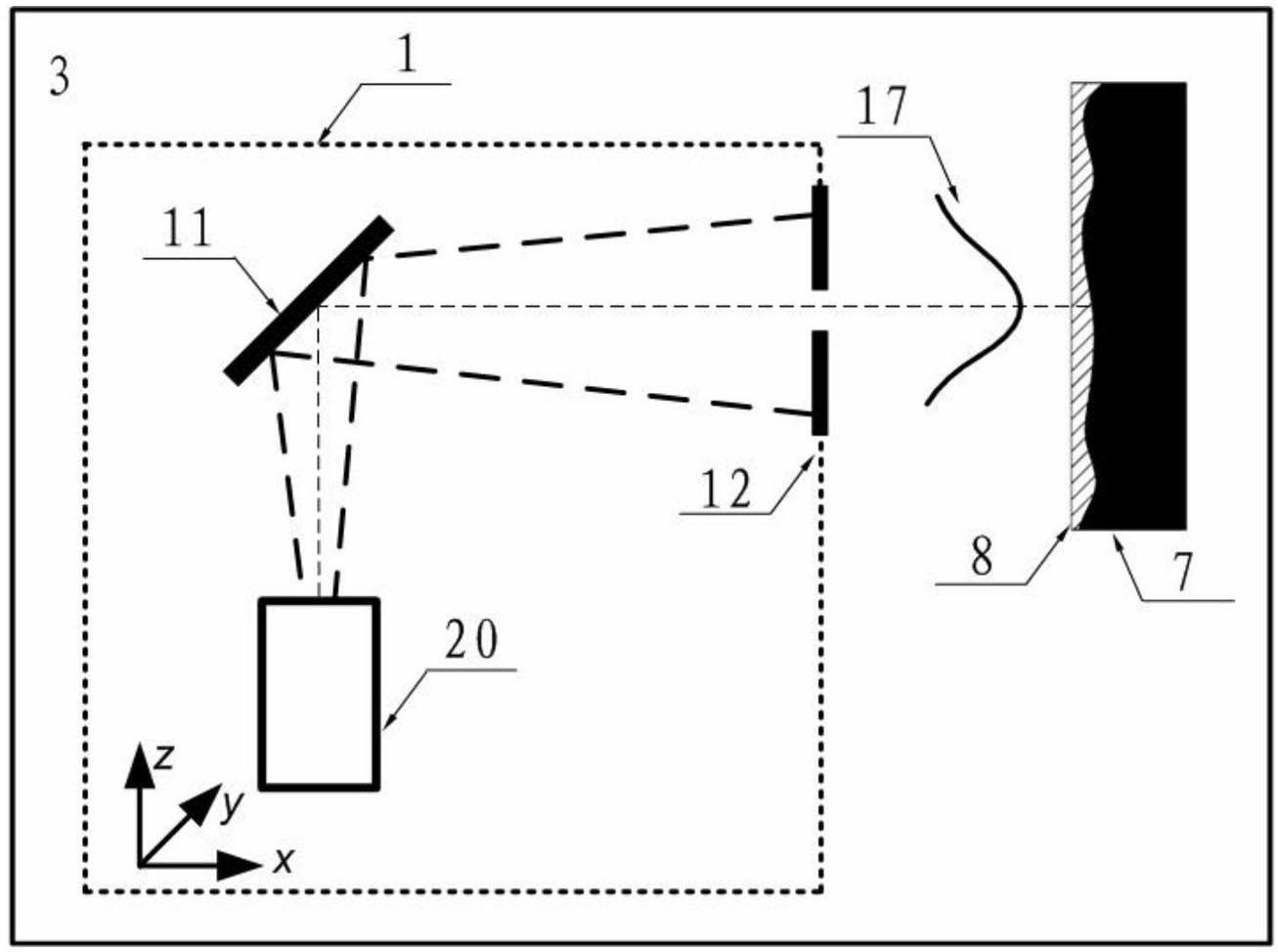

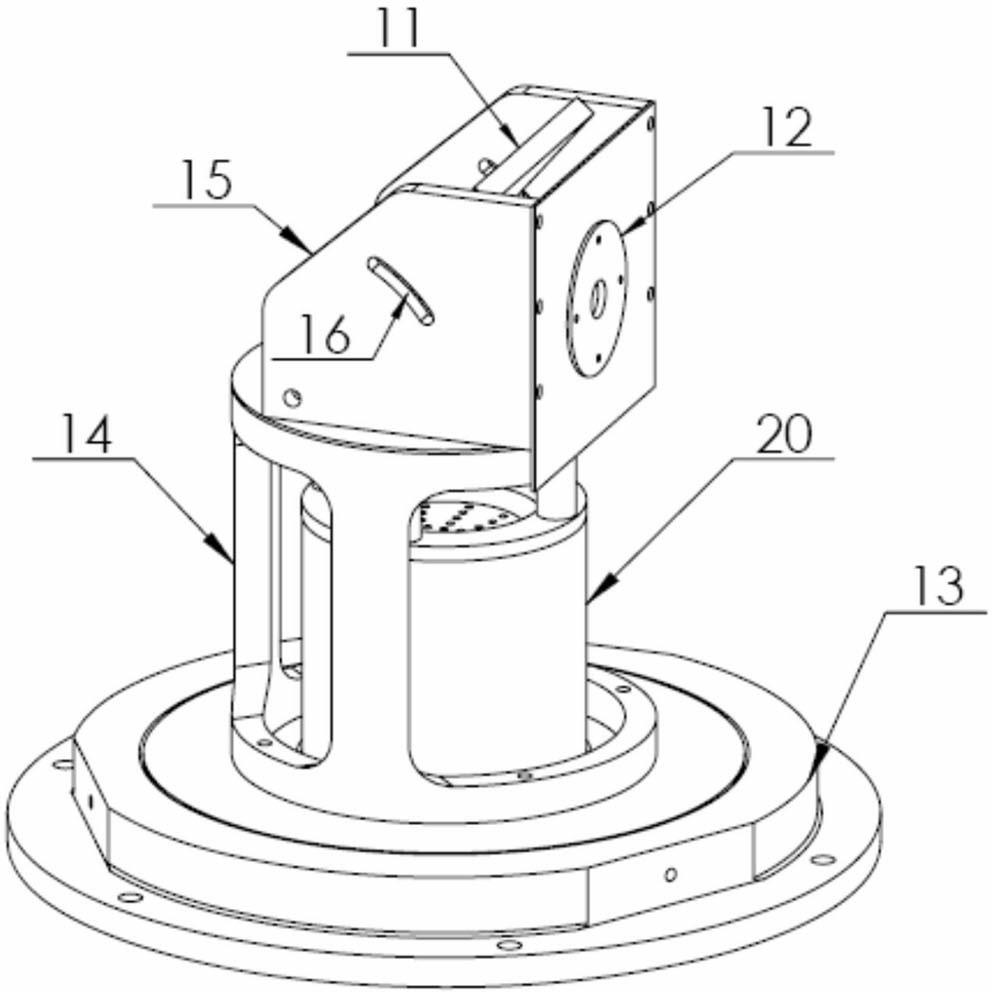

[0048] (1) Obtain the additive function: take an experimental sample of the same material as the workpiece to be processed, and use the wave surface interferometer to measure the initial surface shape error distribution of the experimental sample as follows: Figure 4 As shown; the material addition time is set to 5min, and the ion beam polishing system equipped with an ion beam deterministic addition device is used to add material to a given point of the experimental sample; Measurements are carried out, and the measurement results are as Figure 5 Shown; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com