Manufacturing method and manufacturing device of printing magnetic orientation mother set and magnetic pigment presswork

A manufacturing method and manufacturing device technology, applied in the field of magnetic orientation printing, can solve the problems of waste of permanent magnet rare earth materials, large processing loss, and high processing difficulty, and achieve the goals of saving permanent magnet rare earth materials, increasing service life, and simplifying the manufacturing process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

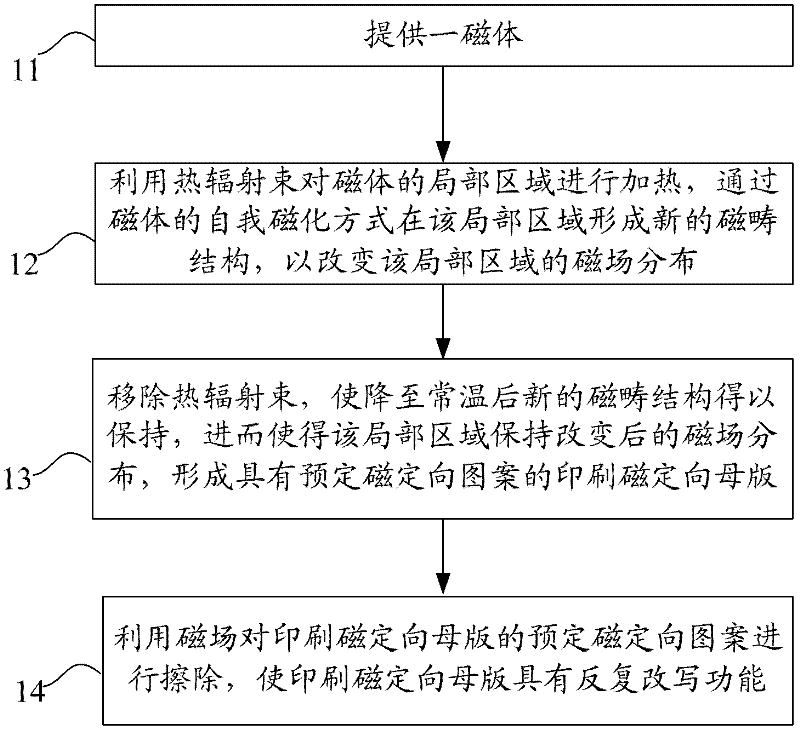

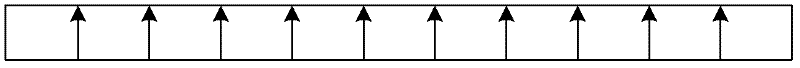

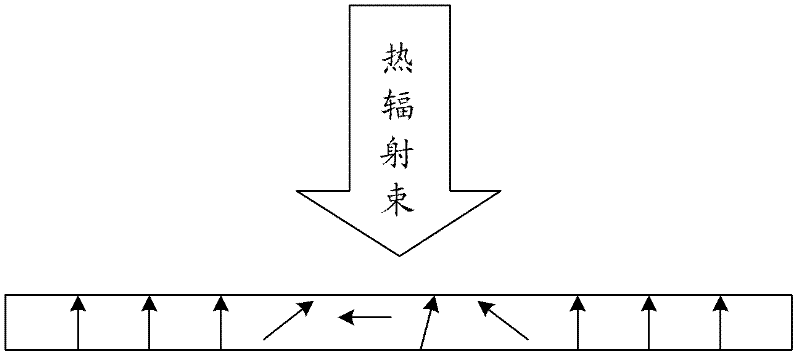

[0024] See Figure 1-Figure 4 , figure 1 It is a flowchart of an embodiment of the manufacturing method of the printed magnetic orientation master of the present invention, Figure 2-Figure 4 yes figure 1 A schematic diagram showing the different steps of the method of manufacturing a printed magnetic orientation master of the present invention.

[0025] In step 11, a magnet is provided.

[0026] The magnet in this step has a specific magnetic field direction, for details, please refer to figure 2 shown. The step may include: magnetizing the layer of magnetizable material along a magnetization direction with a magnetic field to form a magnet. Wherein, the magnet may be a permanent magnet, its surface may be a smooth surface, and its surface shape may be a plane or a curved surface. The magnetic field for magnetizing the layer of magnetizable material can be generated by electromagnetic induction or by permanent magnets.

[0027] In step 12, the local area of the magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com