Vertical interlayer cyclone support-combustion lime kiln

A lime kiln and interlayer technology, which is applied in the field of limestone calcination, can solve problems such as uneven calcination temperature, insufficient heat radiation, and material block extrusion, and achieve the effects of reducing heat energy consumption, stable equipment operation, and stable material level decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with drawings and embodiments.

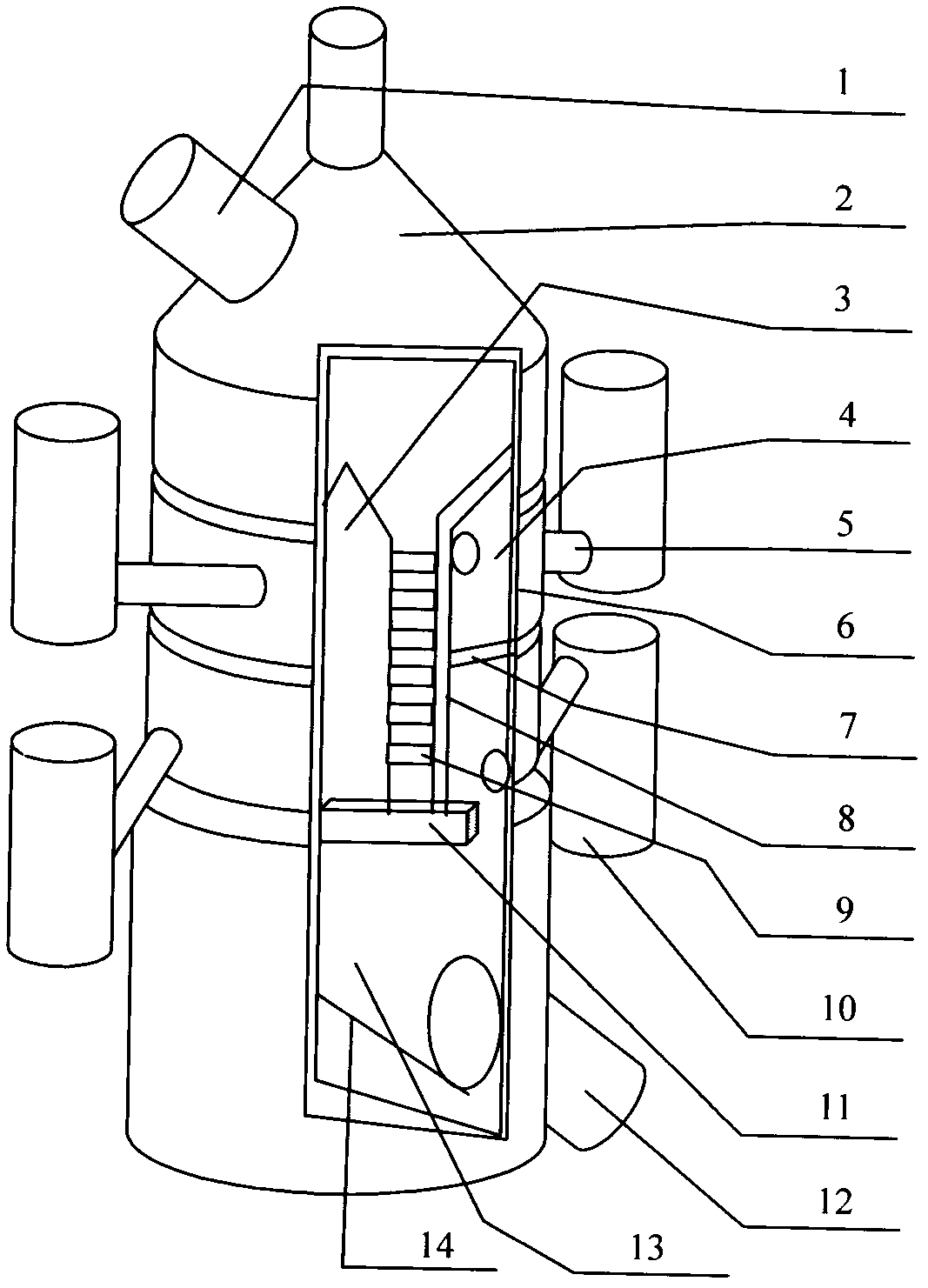

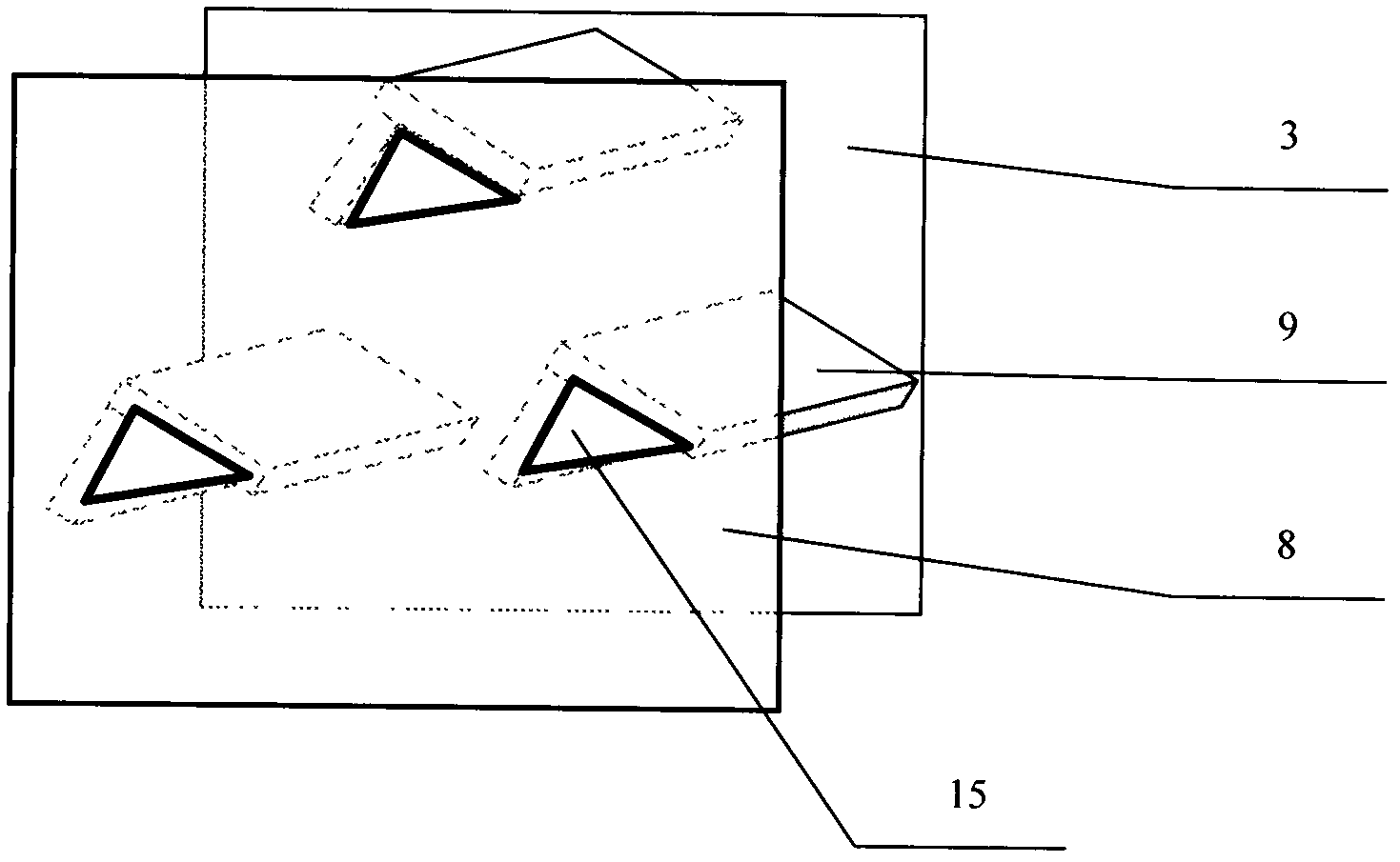

[0013] The top cover 2 at the top of the kiln body is equipped with a charging port 1, and a fixed decompression cone 3 is erected in the center of the kiln body. The fire channel 4 is formed between the kiln outer wall 6 and the inner wall 8, and the interlayer between the decompression cone 3 and the inner wall 8 forms a calcining area. On the inner wall 8 of the fire channel 4 surrounding the interlayer of the calcining area, a fire port 15 is opened into the calcining interlayer, and a supporting frame 9 is installed on the position corresponding to the fire port 15 in the calcining interlayer, and the high-temperature furnace 10 is installed beside the kiln body. The furnace 10 is tangentially connected to the fire channel 4 through the ignition port 5. There is a cooling bucket 13 under the pressure reducing cone 3 in the kiln body. The bottom of the cooling bucket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com