Novel treatment method for anti-oxidation of carbon materials

A carbon material and treatment method technology, applied in the preparation/purification of carbon, graphite, etc., can solve the problems of unsatisfactory anti-oxidation performance, long impregnation time, low impregnation efficiency, etc., achieve good anti-oxidation effect, low cost, The effect of high impregnation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

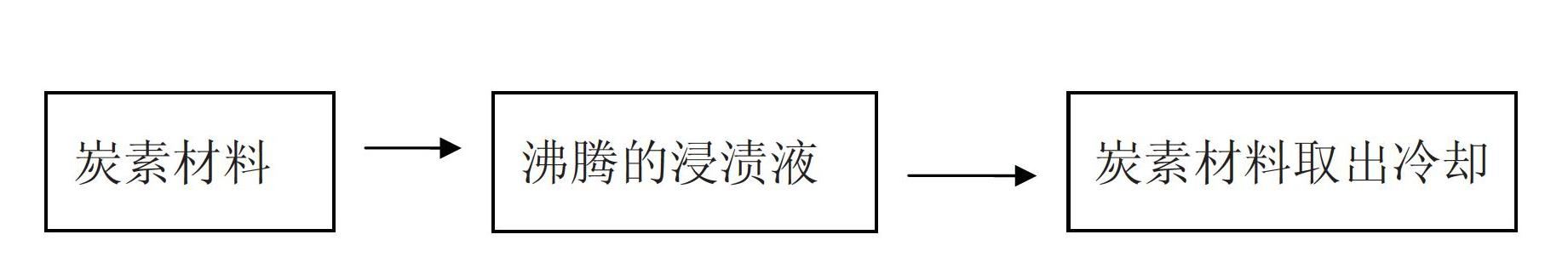

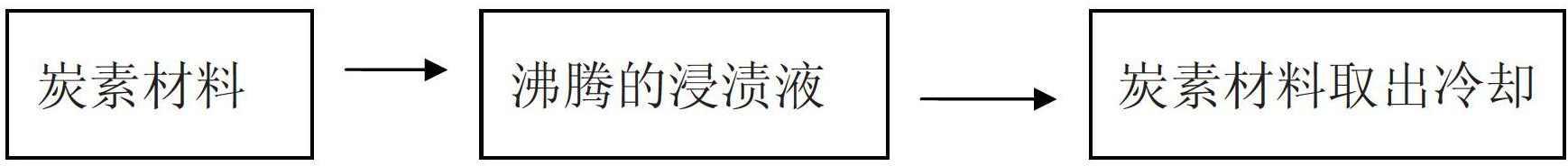

Image

Examples

Embodiment 1

[0028] Boric acid (30%) is put into container, and vacuum heating boils, and vacuum degree is 0.9atm. After boiling, put the graphite anode with the size of 2000mm×150mm×2500mm into the impregnating melt, boil and impregnate for 30min, take out the carbon material and cool it down. The 750°C oxidation resistance of graphite anode after boiling impregnation is 100 times higher than that of unimpregnated graphite anode.

Embodiment 2

[0030] Boric acid (30wt%) is put into container, and concentration is that 20g / l sodium borate is put into boric acid, after stirring evenly, vacuum heating boils, and vacuum degree is 0.9atm. Put the carbon fiber into the impregnating melt, boil and impregnate for 30 minutes, take out the carbon fiber and cool it down. The 700°C oxidation resistance of impregnated carbon fiber is 120 times higher than that without impregnation.

Embodiment 3

[0032] Phosphoric acid (85wt%) was put into the container and heated to boil. After boiling, put the aluminum electrolytic carbon anode with a size of 2000mm×1000mm×2500mm into the impregnation solution, boil and impregnate for 60min, and then take out the carbon anode material and cool it down. The 900°C oxidation resistance of the impregnated carbon anode is 20 times higher than that of the unimpregnated carbon anode.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com