Production method of n-butyl acetate

A technology of n-butyl acetate and its production method, which is applied to the preparation of carboxylic acid esters, chemical instruments and methods, and the preparation of organic compounds, and can solve the problems of wasting energy and water resources, high energy consumption, etc., and achieve the reduction of steam consumption and saving Water resources and the effect of reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

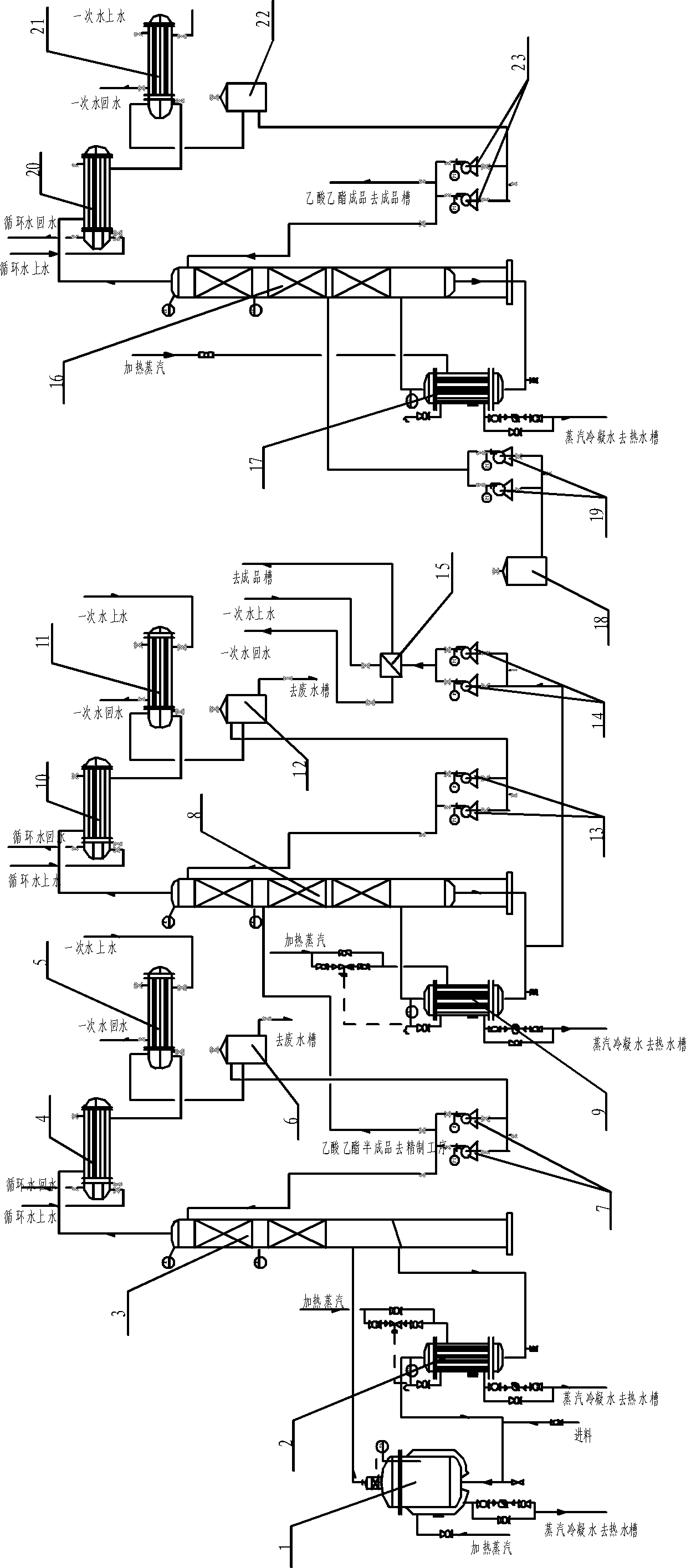

Image

Examples

Embodiment 1

[0033] The production method of n-butyl acetate of the present invention comprises following operation steps:

[0034] ①Esterification

[0035] The raw material butanol and acetic acid react in the esterification kettle 1, and the generated n-butyl acetate and water, after vaporization, carry part of the raw materials into the esterification distillation tower 3, and continue the esterification reaction in the esterification distillation tower 3 and undergo distillation. Separation, the ternary azeotrope of n-butyl acetate, butanol and water distilled from the top of the tower is cooled and condensed by the esterification condenser A 4 and the esterification condenser B 5, and then enters the esterification phase separator 6, and the upper layer of crude ester Through the esterification reflux pump 7, part of it is pumped into the esterification distillation tower 3 as a top reflux; the other part is pumped into the dehydration refining tower 8;

[0036] ②.Dehydration and ref...

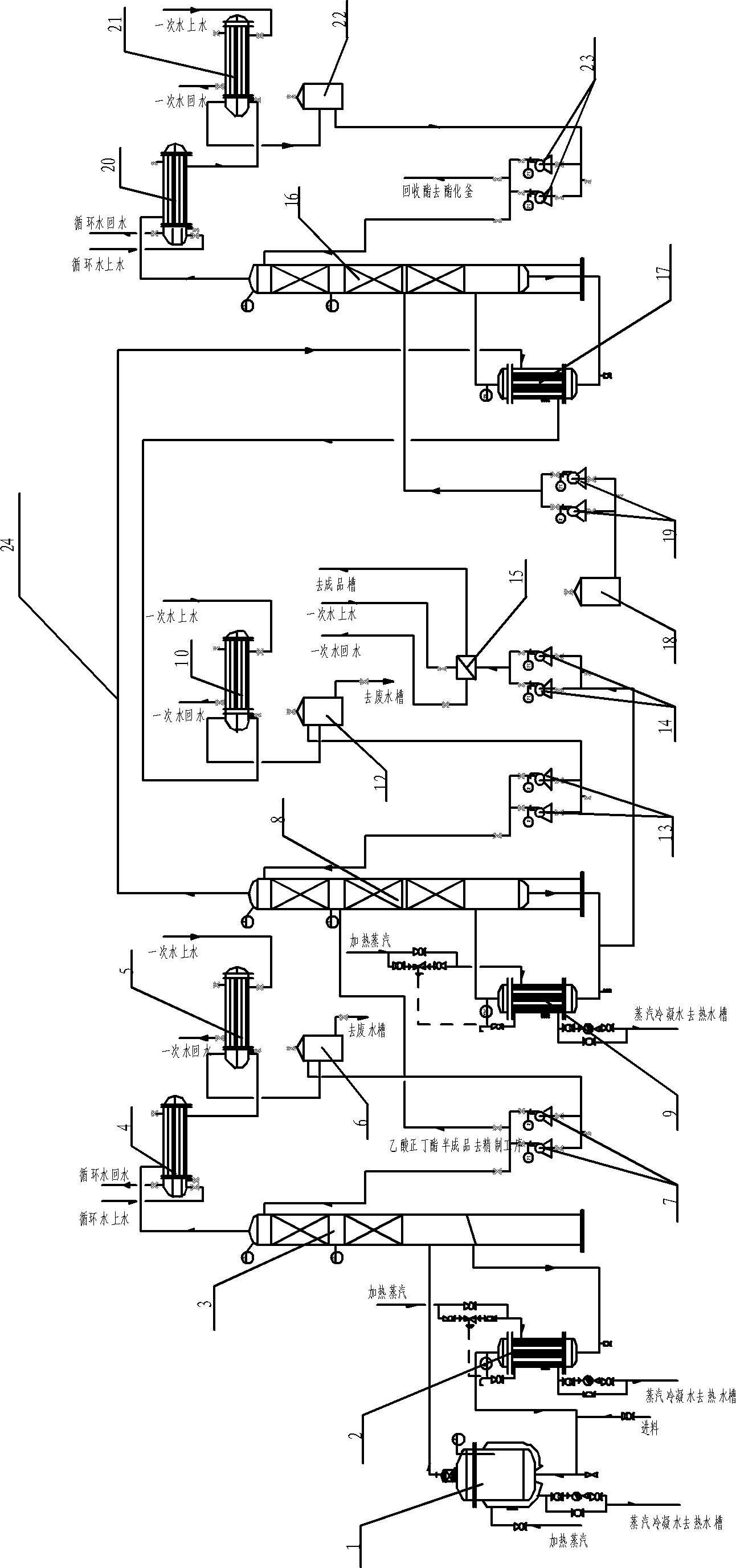

Embodiment 2

[0044] According to the method and steps of embodiment 1, the difference is:

[0045]①. The gas distilled from the top of the dehydration and refining tower 8 enters the reboiler 17 tube of the recovery tower, exchanges heat with the material in the tube, and then enters the auxiliary heat exchanger 25, exchanges heat with the feed of the dehydration and refining tower 8, and condenses The liquid enters the dehydration and refining tower condenser A (10, and then enters the dehydration and refining tower phase separator 12 for stratification, the upper layer of material is sent to the dehydration and refining tower 8 by the reflux pump 13, and the lower layer of material is sent to the waste water tank for collection ; Dehydration refining tower 8 tower kettle material is pumped into n-butyl acetate finished product condenser 15 by n-butyl acetate finished product pump 14, after cooling, obtains ethyl acetate finished product.

[0046] ②. The operating conditions of the dehydr...

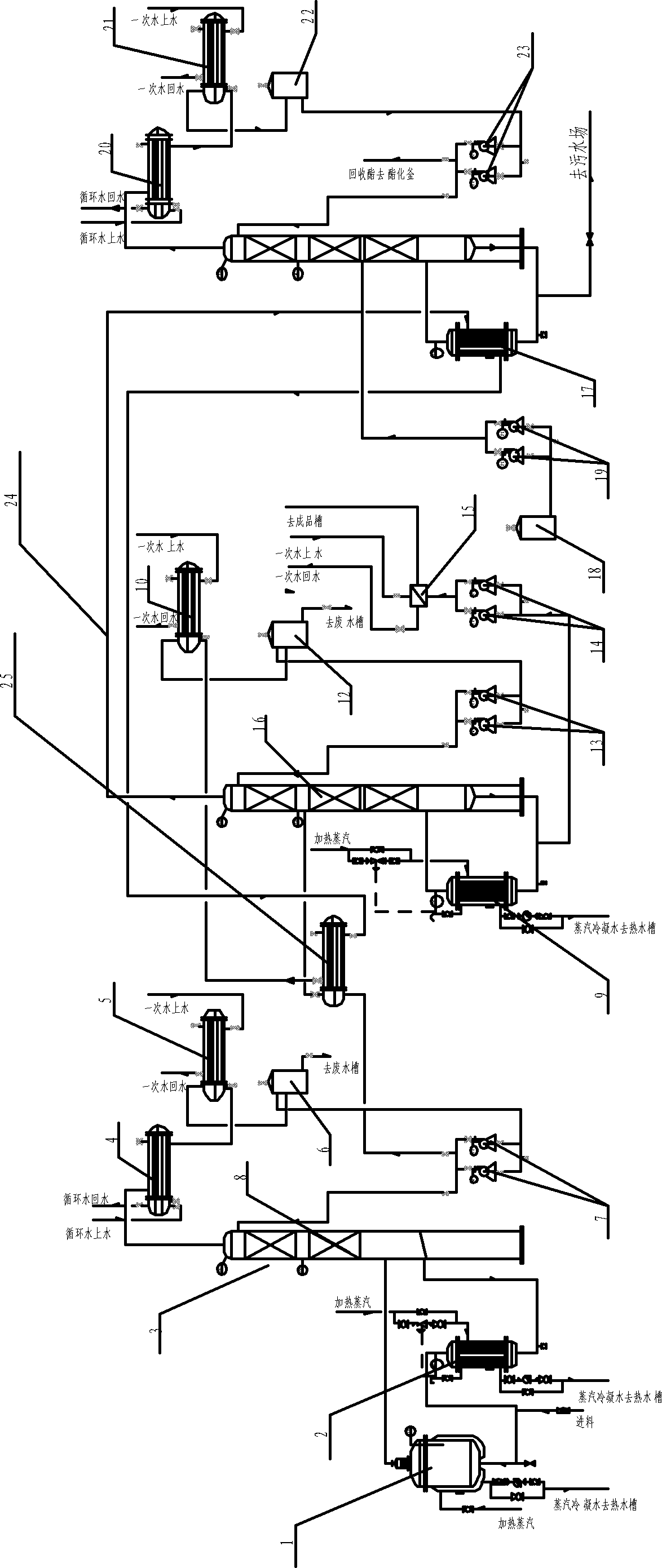

Embodiment 3

[0050] According to the method and steps of embodiment 1, the difference is:

[0051] ①. The gas distilled from the top of the dehydration and refining tower 8 enters the reboiler 17 tube of the recovery tower, and after exchanging heat with the material in the tube, it enters the auxiliary heat exchanger 25, and after exchanging heat with the feed of the dehydration and refining tower 8, no further After being further cooled and condensed by the top condenser of the dehydration refining tower, it directly enters the phase separator 12 of the dehydration refining tower for stratification.

[0052] ②. The operating conditions of the dehydration refining tower 8 are as follows:

[0053]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com