Slow-rebound polyether polyurethane sponge

A technology of polyurethane sponge and slow rebound polyether, which is applied in the field of polyurethane sponge, can solve the problems of low production efficiency, complicated preparation method, softness and hardness and rebound time to be improved, and achieve slow rebound time, high-quality combination, Realize the effect of soft and hard performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

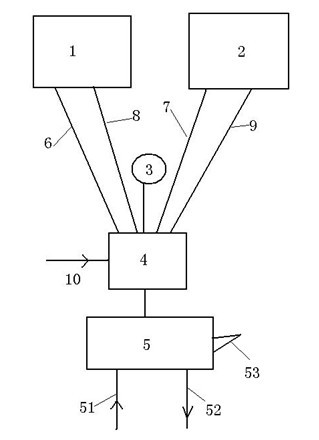

Method used

Image

Examples

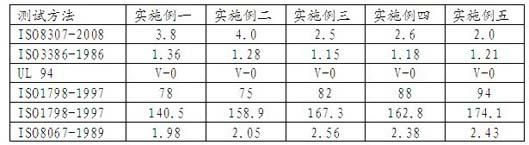

Embodiment 1

[0050] raw material:

[0051] The first polyol: 20 parts by weight; a polymer of ethylene glycol and propylene glycol, with a functionality of 3 and a hydroxyl value of 45 mgKOH / g; the second polyol: a copolymerized polyol of trimethylolpropane and butylene oxide 90 parts by weight, EO content greater than 60%, hydroxyl value 3mgKOH / g; 8 parts by weight of MDI isocyanate; 3 parts by weight of foaming agent formed by cyclopentane and n-butane; 2 parts of triethylenediamine; B8002 surfactant; 0.2 parts by weight of sulfonate flame retardant; 0.2 parts by weight of room temperature vulcanized silicone rubber toughening agent.

[0052] Preparation: Prepare the first polyol and the second polyol in the first raw material tank according to the above raw material ratio, prepare other raw materials in the second raw material tank; stir and mix the raw materials in the first raw material tank in the first mixer Obtain the first mixed liquid evenly, stir and mix the raw materials in th...

Embodiment 2

[0056] raw material:

[0057] The first polyol: a polymer of 85 parts by weight of ethylene glycol and propylene glycol, with a functionality of 3 and a hydroxyl value of 99 mgKOH / g; the second polyol: a copolymerized polyol of trimethylolpropane and butylene oxide 10 parts by weight, EO content 80%, hydroxyl value 22mgKOH / g; 30 parts by weight of MDI isocyanate; 6 parts by weight of foaming agent formed by cyclopentane, n-butane, 5-15% sodium bicarbonate solution; 6 parts of amine; 0.5 parts by weight of sulfonate flame retardant; 0.8 parts by weight of room temperature vulcanized silicone rubber toughening agent.

[0058]

[0059] preparation:

[0060] Prepare the first polyol and the second polyol in the first raw material tank according to the above raw material ratio, prepare other raw materials in the second raw material tank; stir and mix the raw materials in the first raw material tank in the first mixer to obtain For the first mixed liquid, the raw materials in the...

Embodiment 3

[0063] The first polyol: 30 parts by weight of a polymer of ethylene glycol and propylene glycol, with a functionality of 3 and a hydroxyl value of 50 mgKOH / g;

[0064] The second polyol: 60 parts by weight of copolyol with trimethylolpropane and butylene oxide formed by double metal cyanide complex catalyst, EO content 68%, hydroxyl value 8mgKOH / g; MDI isocyanate 15 Parts by weight; 5 parts by weight of cyclopentane foaming agent; 3 parts by weight of triethylenediamine sulfonate flame retardant; 0.5 parts by weight of room temperature vulcanized silicone rubber toughening agent.

[0065]

[0066] preparation:

[0067] Prepare the first polyol and the second polyol in the first raw material tank according to the above raw material ratio, prepare other raw materials in the second raw material tank; stir and mix the raw materials in the first raw material tank in the first mixer to obtain For the first mixed liquid, the raw materials in the second raw material tank are stirre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com