Polyimide, as well as preparation method and application thereof

A technology of polyimide and general formula, applied in the direction of chemical instruments and methods, instruments, liquid crystal materials, etc., can solve the problems of poor friction effect, increase, unfavorable opening ratio, etc., and achieve the effect of improving friction effect and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

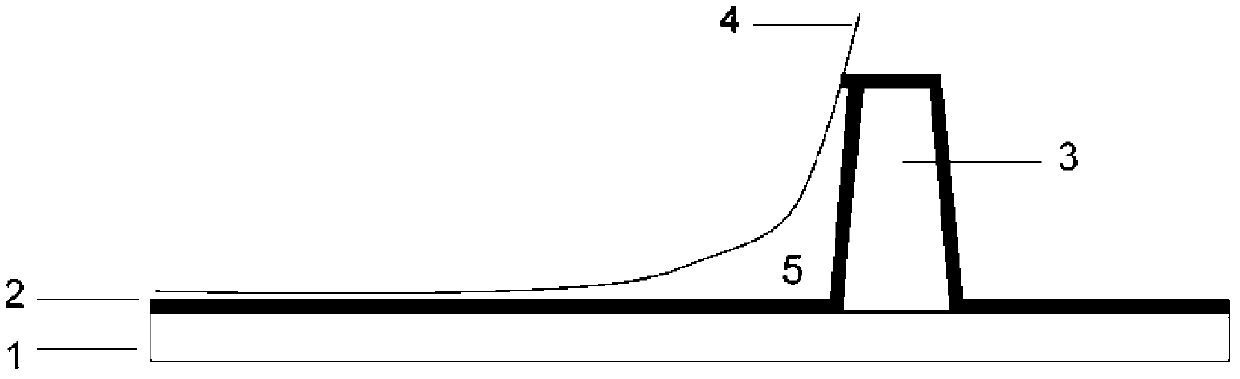

Image

Examples

Embodiment 1

[0032] At room temperature and under nitrogen protection, 20g of p-di-n-hexylcyanopyromellitic dianhydride and 7.8g of p-diaminobiphenyl were mixed and stirred in 200ml of dry NMP (N-methylpyrrolidone) for 24h to obtain the following repeat Unit of polyamic acid liquid.

[0033]

[0034] IR(KBr): 1660cm -1 , 3260-3270cm -1 , 1720cm -1

[0035] Then the polyamic acid liquid obtained above is coated on the surface of the substrate. First, the above-mentioned substrate coated with the polyamic acid liquid is heated at 100° C. for about 2 minutes for pre-curing, and then heated at 230° C. for about 1 h for main curing to obtain a polyimide alignment film.

[0036] IR(KBr): 3260-3270cm -1

[0037] In the infrared spectrum, the stretching vibration of the carbonyl group in the amide group is hardly observed (1660cm -1 ) And the vibration of the carbonyl group of the carboxyl group in the aromatic carboxylic acid (1720cm -1 ), which shows that the amide group and the carboxyl group of the p...

Embodiment 2

[0039] At room temperature, under nitrogen protection, 22.3g terebis(6,6,6-trifluorohexyl)pyromellitic dianhydride and 7.8g p-diaminobiphenyl were mixed and stirred in 200ml dry NMP for 24h to obtain The following repeating unit of polyamic acid liquid.

[0040]

[0041] IR(KBr): 1660cm -1 , 3260-3270cm -1 , 1720cm -1

[0042] Then the polyamic acid liquid obtained above is coated on the surface of the substrate. First, the above-mentioned substrate coated with the polyamic acid liquid is heated at 100° C. for about 2 minutes for pre-curing, and then heated at 230° C. for about 1 h for main curing to obtain a polyimide alignment film.

[0043] IR(KBr): 3260-3270cm -1

[0044] In the same way, it is known that the amide group and carboxyl group of polyamic acid undergo a cyclization reaction to form polyimide.

Embodiment 3

[0046] Under the protection of nitrogen at room temperature, 21g of p-bis(4-acetylbutyl)pyromellitic dianhydride and 7.8g of p-diaminobiphenyl were mixed and stirred for 24h in 200ml of dry NMP to obtain the following repeating unit Polyamic acid liquid.

[0047]

[0048] IR(KBr): 1660cm -1 , 3260-3270cm -1 , 1720cm -1

[0049] Then the polyamic acid liquid obtained above is coated on the surface of the substrate. First, the above-mentioned substrate coated with the polyamic acid liquid is heated at 100° C. for about 2 minutes for pre-curing, and then heated at 230° C. for about 1 h for main curing to obtain a polyimide alignment film.

[0050] IR(KBr): 3260-3270cm -1

[0051] In the same way, it is known that the amide group and carboxyl group of polyamic acid undergo a cyclization reaction to form polyimide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com