Mild safe liquid laundry detergent and preparing method thereof

A laundry detergent, a safe technology, applied in the field of laundry detergent, to achieve mildness guarantee, safety guarantee, and increase the effect of moisturizing and skin care

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

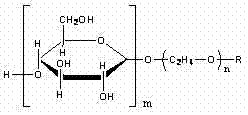

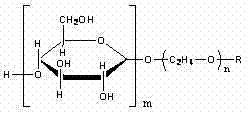

Image

Examples

Embodiment 1

[0031] A kind of washing liquid, its weight percentage composition:

[0032] C 1214 Fatty alcohol polyoxyethylene ether (EO=9): 5.0%

[0033] C 1214 Fatty alcohol polyoxyethylene ether (EO=3) glycoside: 5.0%

[0034] Alcohol ether carboxylate C 1214 -(EO) 9 -COONa: 5.0%

[0035] Sodium carboxymethylcellulose: 0.5%

[0036] Fragrance 0.1%

[0037] Pigment 0.001%

[0038] CMIT / MIT 0.2%

[0039] Deionized water: balance

[0040] The preparation process is:

[0041] Preparation of liquid A: add 40% of the total weight of deionized water into the chemical tank and heat to 80°C, add fatty alcohol polyoxyethylene ether, fatty alcohol polyoxyethylene ether glycoside, and alcohol ether carboxylate while stirring according to the above raw material ratio , the amount added is based on the total content of the finished laundry detergent, and stirred for 0.5 hours after dissolving to make it uniform.

[0042] Preparation of liquid B: add 40% of the total weight of deionized wa...

Embodiment 2

[0045] A kind of washing liquid, its weight percentage composition:

[0046] C 1618 Fatty alcohol polyoxyethylene ether (EO=13): 4.0%

[0047] C 1214 Fatty alcohol polyoxyethylene ether (EO=2) glycoside: 7.0%

[0048] Alcohol ether carboxylate C 1214 -(EO) 10 -COONa 4.5%

[0049] Sodium alginate: 0.25%

[0050] Fragrance 0.2%

[0051] Pigment 0.001%

[0052] CBS 0.1%

[0053] Deionized water: balance

[0054] The preparation process is:

[0055] Preparation of liquid A: add 30% of the total weight of deionized water into the chemical tank and heat to 70°C, add fatty alcohol polyoxyethylene ether, fatty alcohol polyoxyethylene ether glycoside, and alcohol ether carboxylate while stirring according to the above raw material ratio , the amount added is based on the total content of the finished laundry detergent, and stirred for 1 hour after dissolving to make it uniform.

[0056] Preparation of liquid B: add 30% of the total weight of deionized water into the chemica...

Embodiment 3

[0059] A kind of washing liquid, its weight percentage composition:

[0060] C 1214 Fatty alcohol polyoxyethylene ether (EO=15): 2.0%

[0061] C 1214 Fatty alcohol polyoxyethylene ether (EO=1) glycoside: 9.0%

[0062] Alcohol ether carboxylate C 1618 -(EO)15 -COONa: 4.0%

[0063] Sodium alginate: 0.25%

[0064] Sodium carboxymethylcellulose: 0.25%

[0065] Fragrance 0.4%

[0066] Pigment 0.002%

[0067] CMIT / MIT 0.2%

[0068] Deionized water: balance

[0069] The preparation process is:

[0070] Preparation of liquid A: Add 35% of the total weight of deionized water into the chemical tank and heat to 75°C, add fatty alcohol polyoxyethylene ether, fatty alcohol polyoxyethylene ether glycoside, and alcohol ether carboxylate while stirring according to the above raw material ratio , the amount added is based on the total content of the finished laundry detergent, and stirred for 0.75 hours after dissolving to make it uniform.

[0071] Preparation of liquid B: add 35% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com