Dry-method anaerobic fermentation device

A fermentation device, dry anaerobic technology, applied in biochemical cleaning devices, enzymology/microbiology devices, solid-phase fermentation bioreactors, etc. Problems such as poor heat transfer effect, to achieve the effect of solving upper scum, preventing crusting, and avoiding poor heating heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions of the present invention will be described in detail below with reference to the accompanying drawings and preferred embodiments.

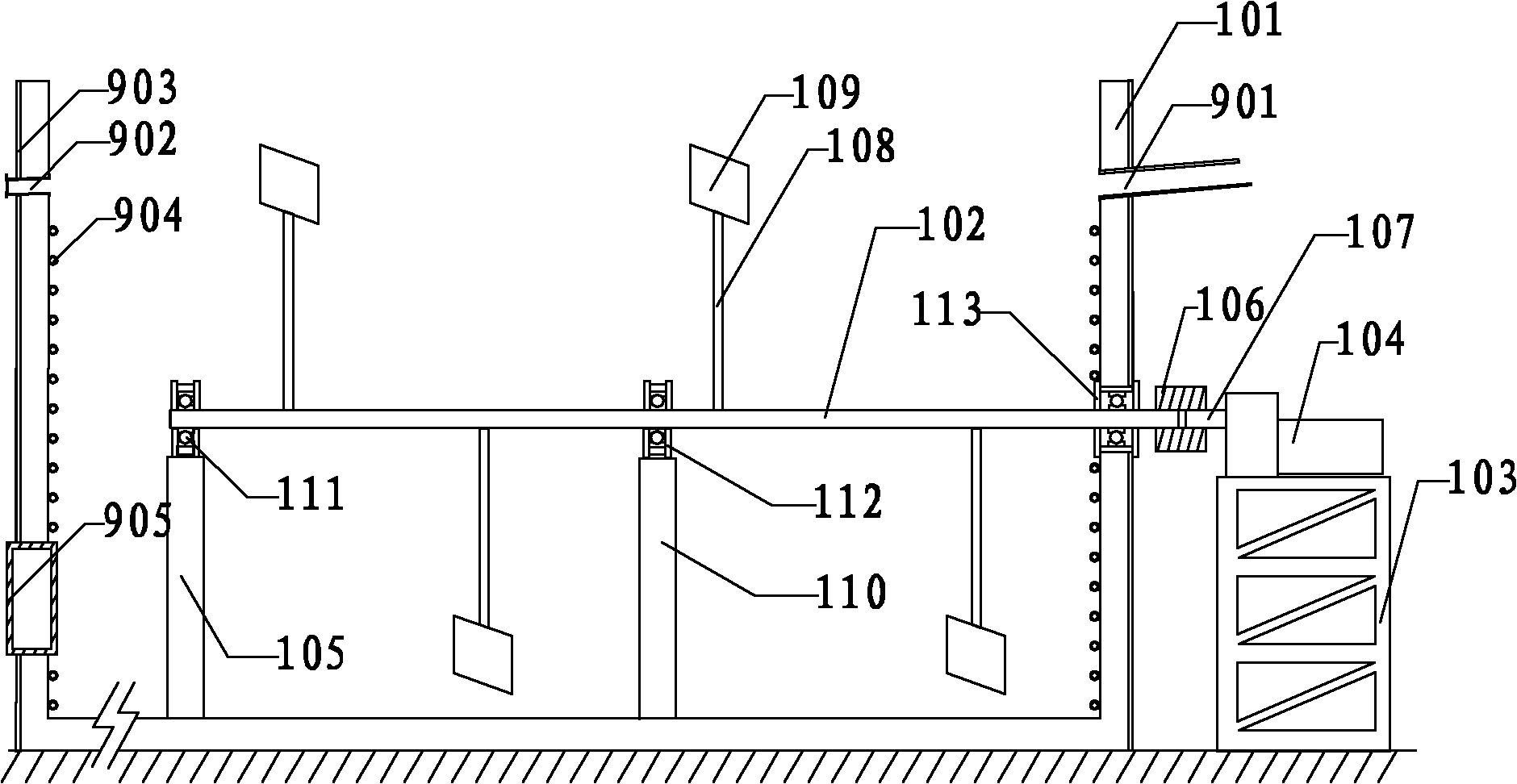

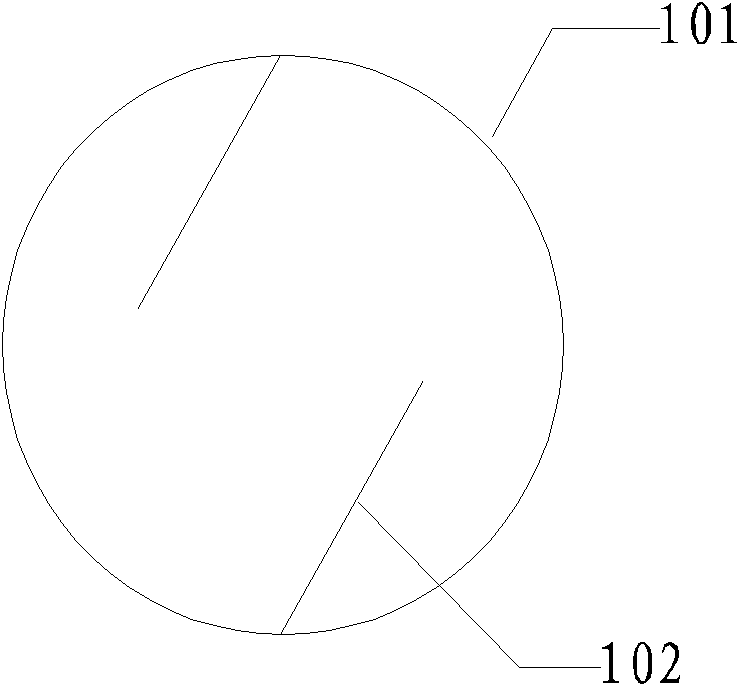

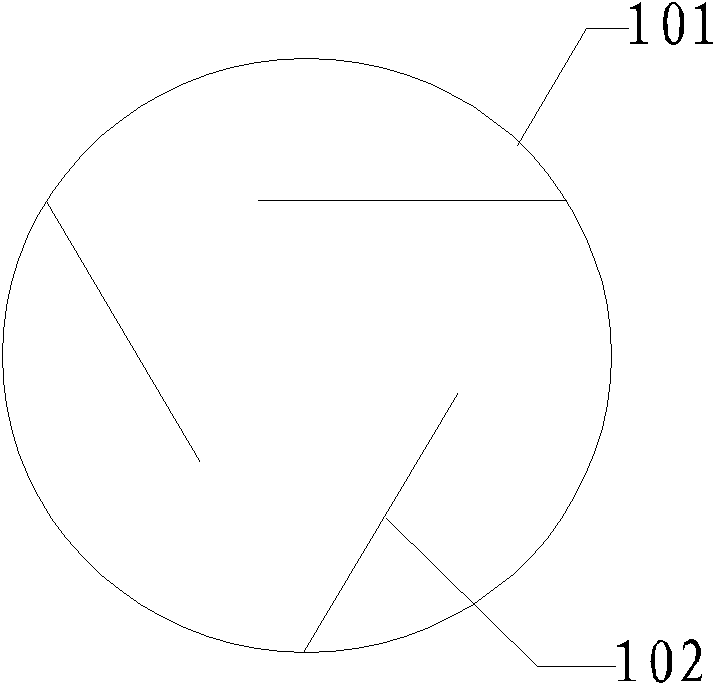

[0034] Such as figure 1 Shown is a schematic cross-sectional structure diagram of a dry anaerobic fermentation device in the present invention. The present invention includes: a fermentation tank 101 , a stirring shaft 102 , a first support 103 and a motor 104 . The structure of the fermenter 101 is a cylindrical tank, the fermenter 101 has a stirring shaft hole, and the upper surface of the bottom of the fermenter 101 is provided with a second bracket 105 . One end of the stirring shaft 102 is arranged on the upper part of the second bracket 105, and the other end passes through the hole of the stirring shaft. A shaft coupling 106 is provided on one end of the stirring shaft 102 exposed outside the fermenter 101 . A first bracket 103 is also installed on the outside of the fermenter 101 , the motor 104 is placed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com