Impeller-type energy feedback shock absorber

A shock absorber and impeller technology, which is applied in the field of devices in the field of vehicle technology, can solve the problems of increasing the difficulty of subsequent voltage and current processing circuits, frequent changes in the rotation direction of the generator rotor, and increasing the complexity of the system. Small size, good energy feeding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment example, the present invention will be further described:

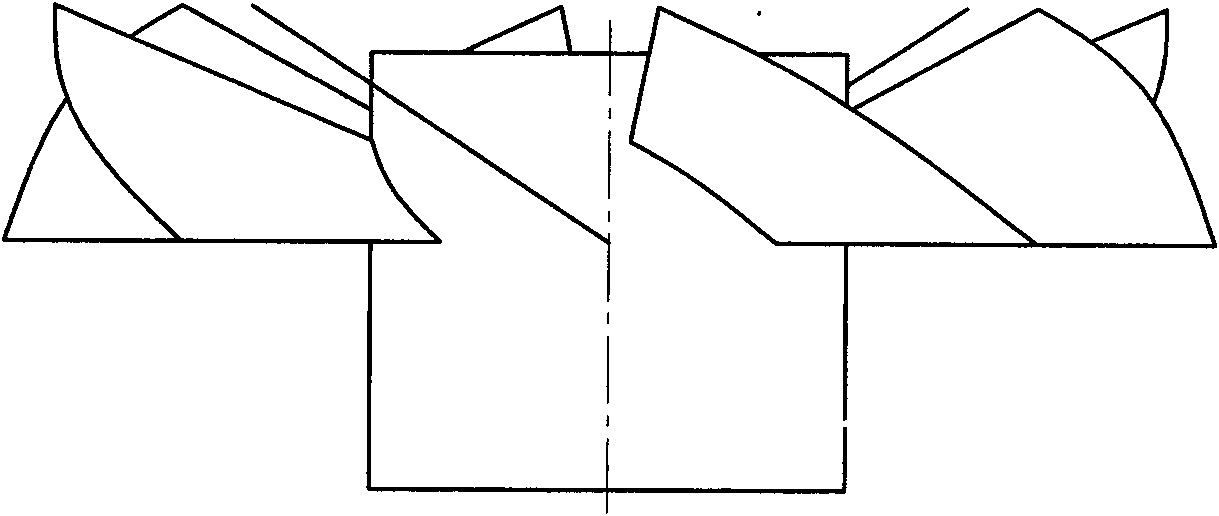

[0020] When the vehicle is running, the cylinder and the piston rod of the shock absorber will move relative to each other due to the unevenness of the road surface, which will stimulate the fluid in the cylinder to flow back and forth between the upper and lower chambers. The invention converts it into unidirectional rotation motion through a special impeller device, and then drives the generator rotor to run in one direction to generate electricity for use by electrical equipment on vehicles.

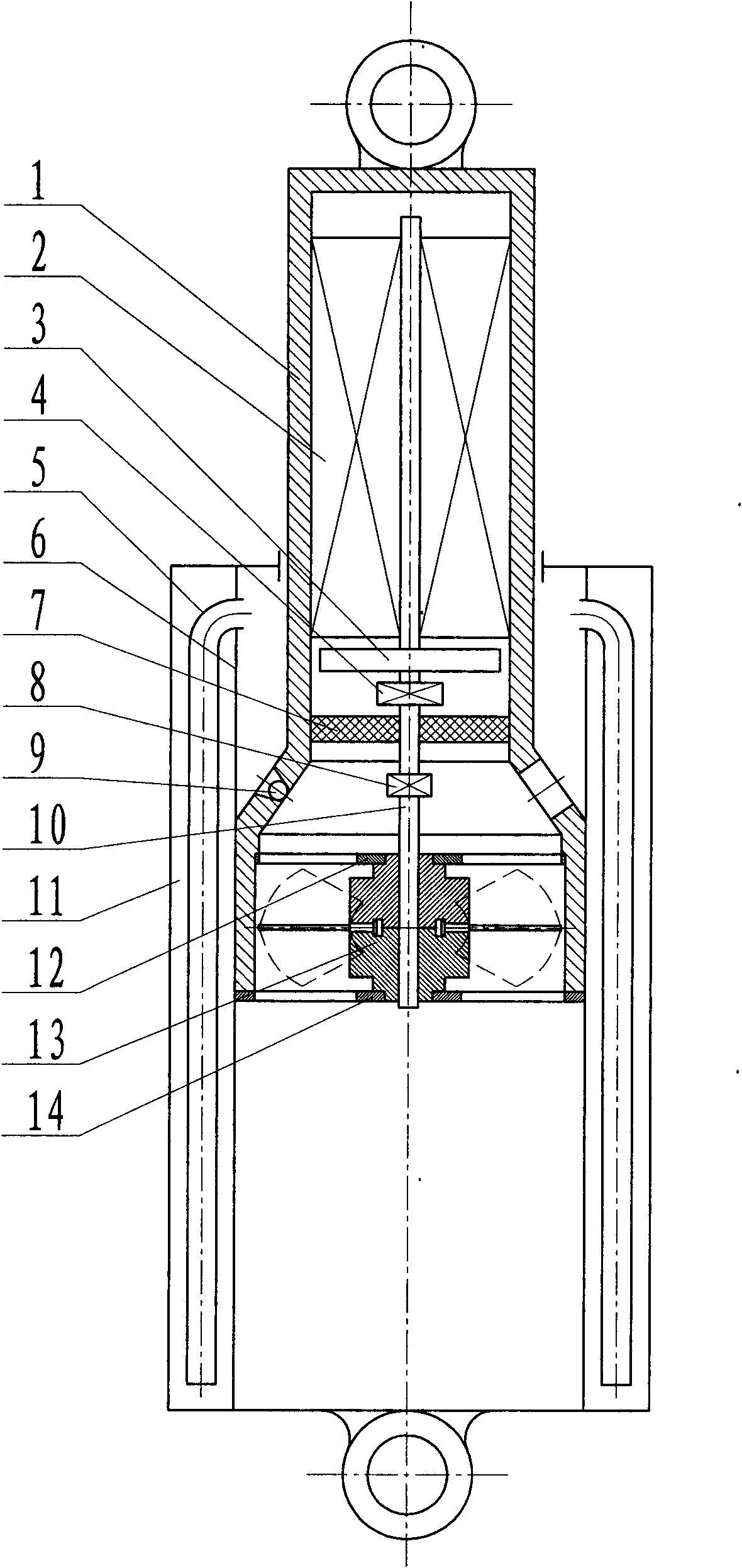

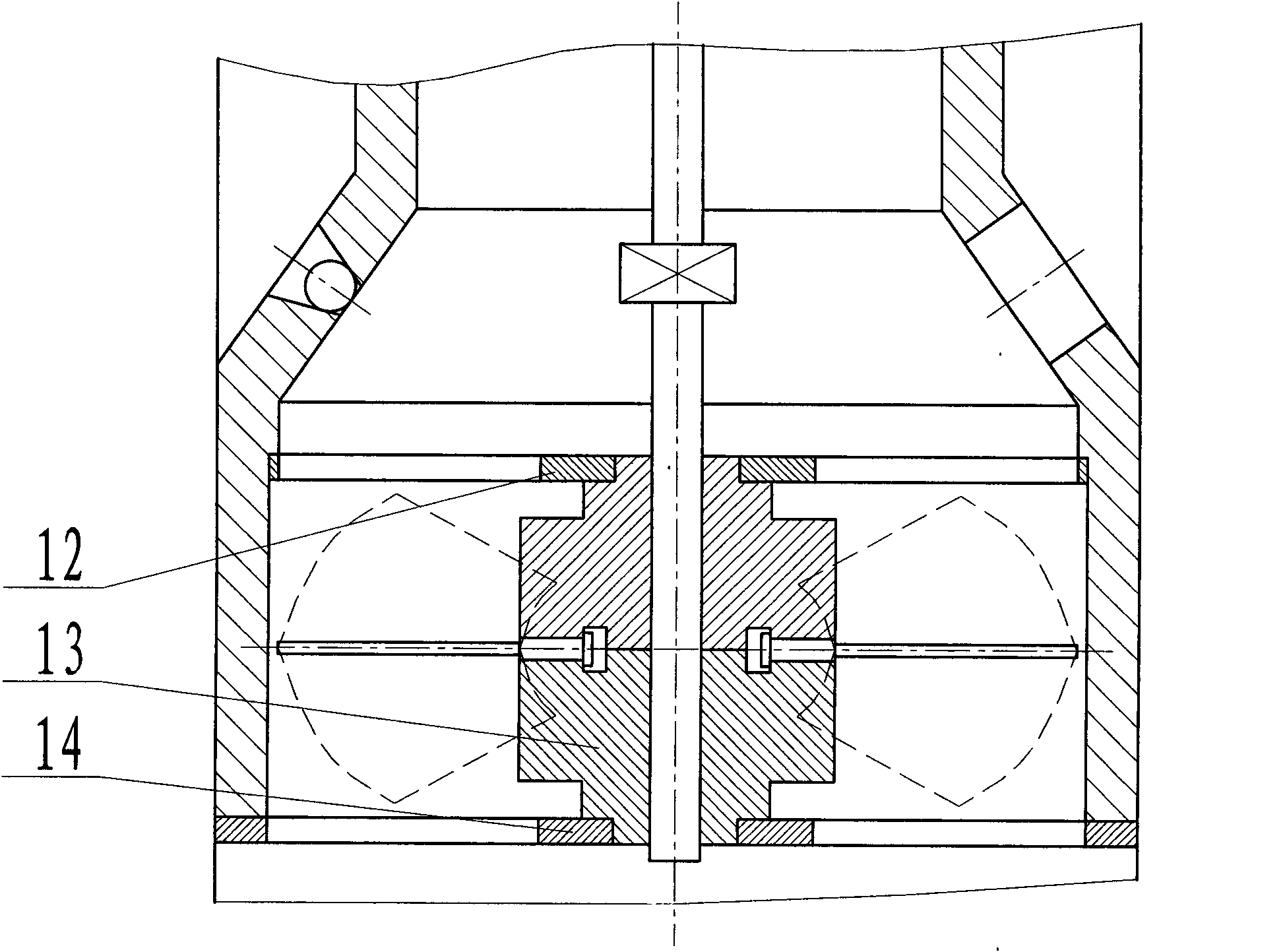

[0021] As shown in the figure: the energy-feeding shock absorber includes a shock-absorbing pressure cylinder, an energy conversion device and ancillary devices. Wherein the damping pressure cylinder includes a cylinder body 6 containing fluid and a hollow piston rod 1 containing an energy conversion device; the energy conversion device includes an impeller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com