Rapid low-cost measuring method for fiber length

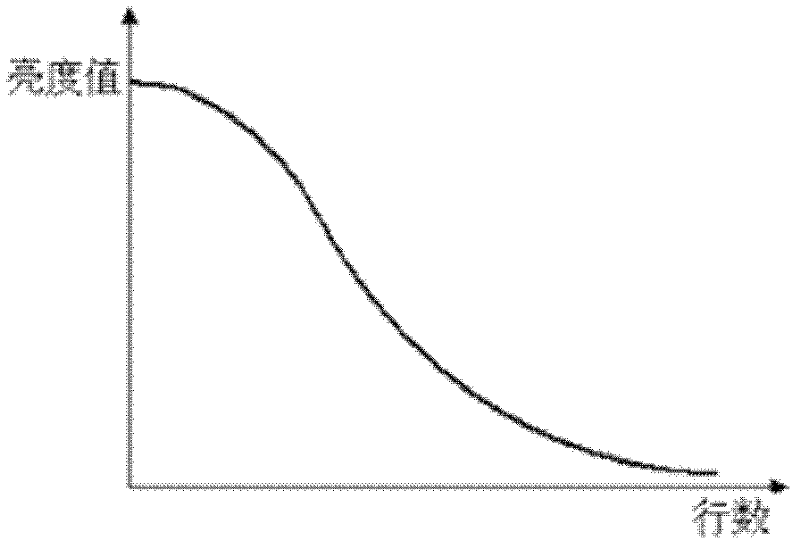

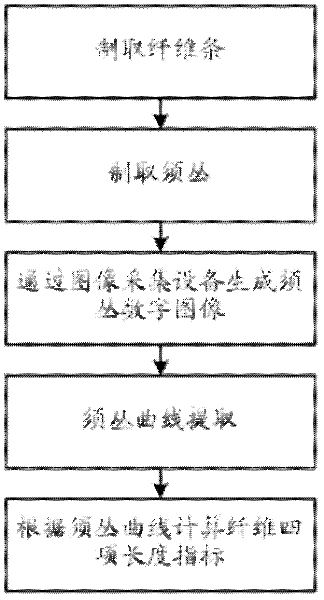

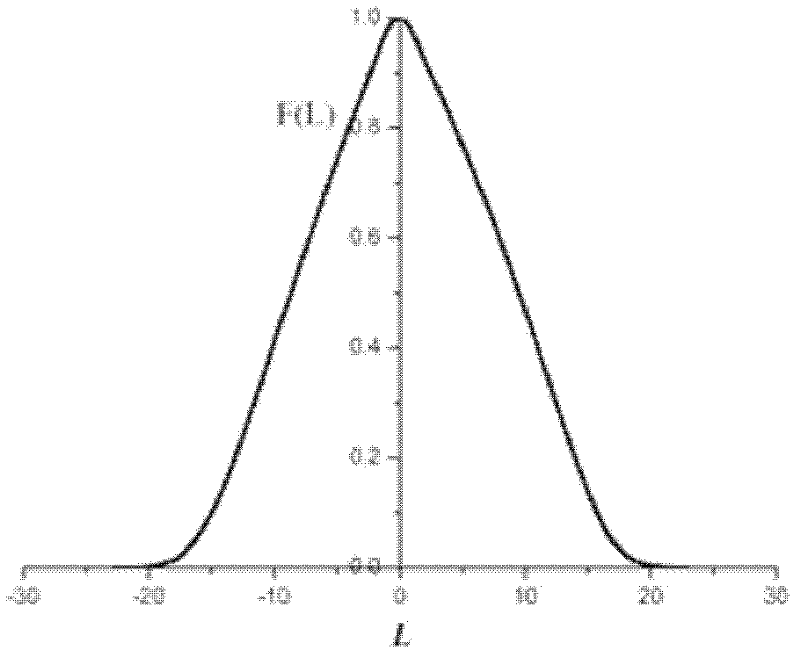

A fiber length and measurement method technology, which is applied in the direction of measuring devices, instruments, and optical devices, can solve the problems of fuzzy description of length calculation methods, pixel distortion at the edge of the camera, and poor signal accuracy, so as to facilitate popularization and promotion , fast and accurate measurement, and convenient equipment maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0098] (1) Take 300mg kapok fiber, remove the larger impurities, loosen it, mix it evenly, and then stretch it through the fiber stretcher for 5 times, so that the fibers are straightened, parallel and randomly arranged along the axis of the fiber strip, and a fiber strip is made. Mix evenly, straight and clean fiber strips.

[0099] (2) Randomly clamp any cross-section of the fiber strip with a clamp, make the clamping line perpendicular to the axis of the fiber strip, tear off the unclamped fiber, and insert the fiber strip from above or below with a special comb parallel jaw , comb to remove the floating fibers, and then use another clamp to clamp the beard clusters close to the jaws of the original clamp, remove the initial clamp, and repeat the above operation to comb the other end of the floating fibers to make a double-sided fiber with a width of about 5 cm and a weight of about 30 mg. Whiskers for terminal testing.

[0100] (3) Digital image acquisition: spread the pr...

Embodiment 2

[0104] (1) Select a section of sliver from the semi-finished product, randomly clamp any cross-section of the sliver with clamps, make the clamping line perpendicular to the axis of the fiber strip, tear off the unclamped fibers, and use a special comb to clamp in parallel Insert the fiber strip from the top or bottom of the jaw, comb out the floating fibers, and then clamp the whiskers with another clamp close to the jaw of the original clamp, remove the initial clamp, and repeat the above operation to comb out the floating fibers at the other end. A double-ended test whisker with a width of about 5.5 cm and a weight of about 0.05 g was formed.

[0105] (2) Digital image acquisition: spread the prepared whiskers on the glass tray of a professional film scanner, and the clamping line is perpendicular to the X-axis of the scanner. Set the scan type: grayscale; resolution: 2000dpi; scan medium: positive film; attribute: reversed; brightness, dark tone, contrast, and color correc...

Embodiment 3

[0109] (1) The polyester fiber web is prepared by carding with a small carding machine, and 0.50g of fiber is taken from it, and stretched 3 times with a fiber stretcher, so that the fibers are straightened along the fiber strip axis, parallel and randomly arranged, and a mixed uniform , Straight and smooth fiber strips.

[0110] (2) Randomly clamp any cross-section of the fiber strip with a clamp, make the clamping line perpendicular to the axis of the fiber strip, tear off the unclamped fiber, and insert the fiber strip from above or below with a special comb parallel jaw , comb to remove the floating fibers, and then use another clamp to clamp the beard clusters close to the jaws of the original clamp, remove the initial clamp, and repeat the above operation to comb the other end of the floating fibers, making a width of about 5.5cm and a weight of about 0.04g The paired-ended test with whiskers.

[0111] (3) Digital image acquisition: spread the prepared whiskers on the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com