Method for controlling direct-current (DC) frequency conversion air condition compressor

An air conditioner compressor and control method technology, applied in the direction of motor generator control, electronic reversing motor control, control system, etc., can solve the problems of weak spatial saliency, no application, poor effect, etc., and achieve start-up noise Small size, good energy saving, impact-resistant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

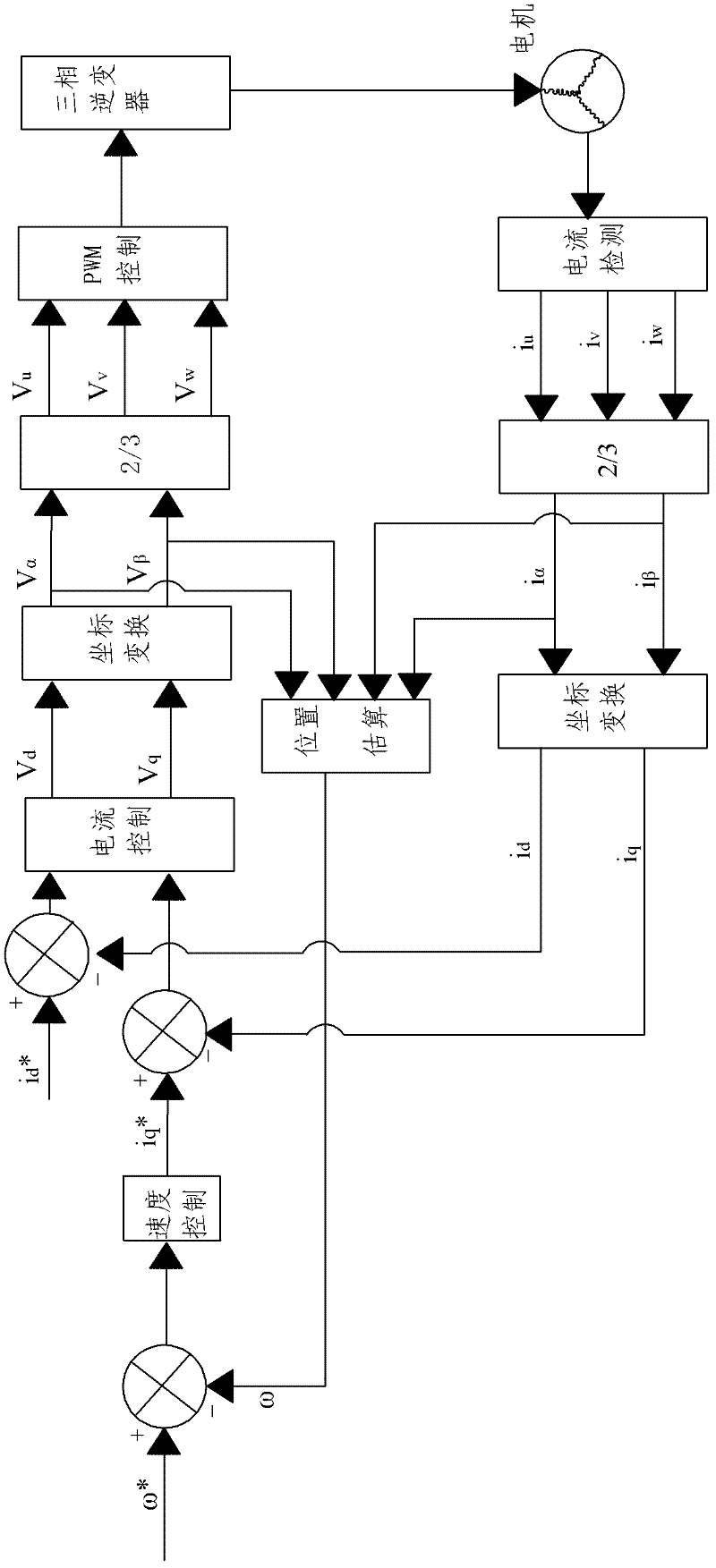

[0025] see figure 1 , the mathematical model of the permanent magnet synchronous motor in the three-phase stationary coordinate system is a multivariable, nonlinear, and strongly coupled complex system, and it is often very difficult to analyze and solve the equations in this coordinate system. The vector transformation control technology uses the transformation from the stationary coordinate system to the rotating coordinate system to realize the decoupling of the excitation component and the torque component in the stator current, so that the permanent magnet synchronous motor can separate the magnetic flux and the torque component like a DC motor. Torque is independently controlled. Among them, the stationary coordinate system is the α and β coordinate systems forming a 90-degree right angle to each other, and the rotating coordinate system is the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com