Preparation method for flat peach wine

A flat peach and fruit wine yeast technology, which is applied in the field of wine making, can solve the problems that hinder the development of peach planting in Pinggu District, the concentrated supply time of large peaches, and the oversupply of production, and achieve the effect of changing the degree of fermentation that is difficult to control, rich in taste, and high in quality of brewed products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

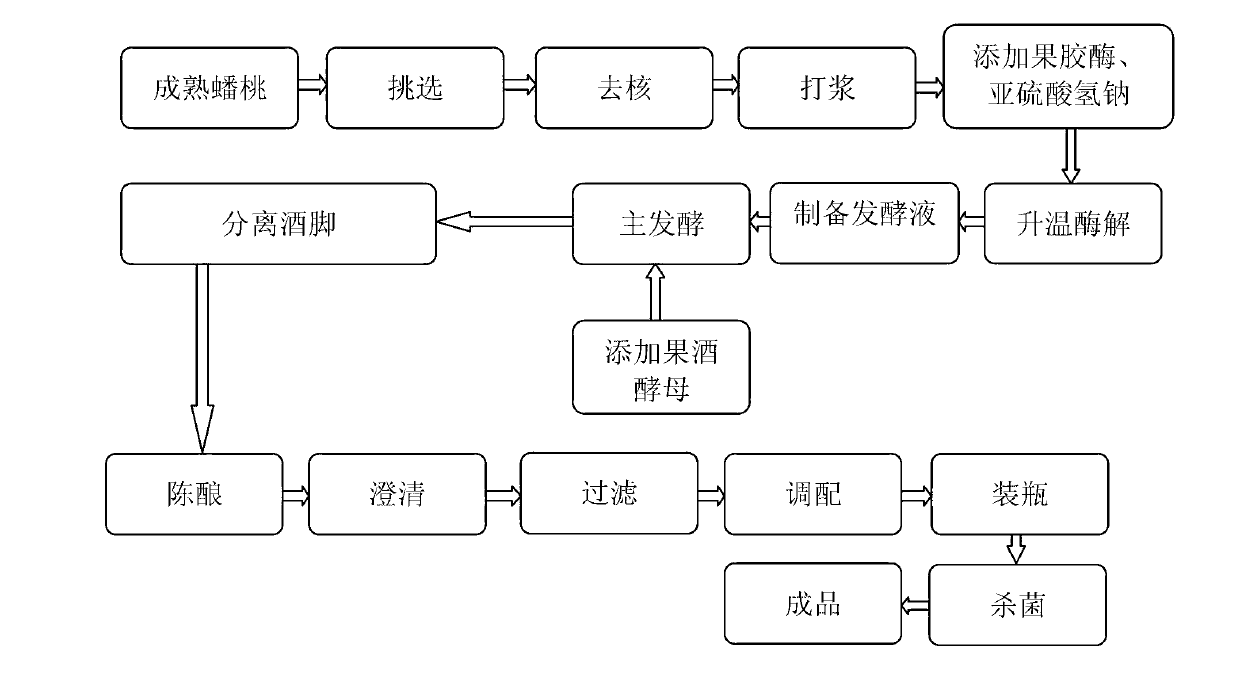

[0019] Apply the method provided by the invention to carry out the preparation of flat peach wine, method flow process is as figure 1 As shown, the specific steps are as follows:

[0020] The first step is the selection of flat peaches for fermentation: select flat peaches that are free from diseases and insect pests and are 90% to 100% mature, and remove the pits; put them in a room with a temperature of 20°C for 3 days to soften.

[0021] The second step, the preparation of flat peach enzymatic hydrolysis solution: beat the softened flat peach, add pectinase and sodium bisulfite in the flat peach juice after beating, so that the mass percentage of the described pectinase is 0.01%, sulfurous acid The add-on of sodium hydrogen is that concentration is 60mg / L. Then raise the temperature to 30°C, enzymatically hydrolyze for 2 hours, and filter with a filter.

[0022] The third step, the preparation of fermented liquid:

[0023] Add sucrose to the pan peach enzymolysis solutio...

Embodiment 2

[0031] Application of the preparation method provided in the present invention, a preferred embodiment adopts the following process parameters and steps to realize:

[0032] The first step is the selection of flat peaches for fermentation: select flat peaches that are free from diseases and insect pests and are 90% to 100% mature, and remove the pits; put them in a room with a temperature of 20°C for 3 days to soften.

[0033] The second step, the preparation of flat peach enzymatic hydrolysis solution: beat the softened flat peach, add pectinase and sodium bisulfite in the flat peach juice after beating, so that the mass percentage of the described pectinase is 0.05%, sulfurous acid The concentration of sodium hydrogen is 80mg / L. Then raise the temperature to 40°C, enzymatically hydrolyze for 3 hours, and filter with a filter.

[0034] The third step, the preparation of fermented liquid:

[0035] Add sucrose to the pan peach enzymolysis solution and adjust the sugar concent...

Embodiment 3

[0043] Embodiment 3 In another preferred embodiment, adopt following steps to prepare flat peach wine:

[0044] The first step is the screening of flat peaches for fermentation: select flat peaches with no pests and diseases and high maturity (90% to 100% mature), and remove the pits. Put it in a room with a temperature of 25°C, and it will soften in 2-3 days.

[0045] The second step, the preparation of the flat peach enzymatic hydrolysis solution: beat the softened flat peach, add pectinase and sodium bisulfite to the beaten peach juice, then raise the temperature to 35° C., enzymolyze for 3 hours, and filter with a filter. The added amount of the pectinase is 0.025% by mass, and the concentration of the sodium bisulfite is 60mg / L.

[0046] The third step, the preparation of fermented liquid:

[0047] Adjust the sugar concentration and pH value of the pan peach enzymolysis solution, add sucrose to the pan peach enzymolysis solution and adjust the sugar concentration to 21%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com