Coupling control method for temperature field in process of super-quickly cooling rolled moderate-thick plate

A coupled control, ultra-fast cooling technology, applied in temperature control and other directions, can solve problems such as oscillation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

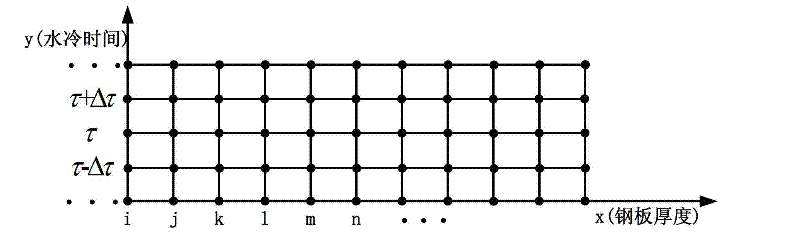

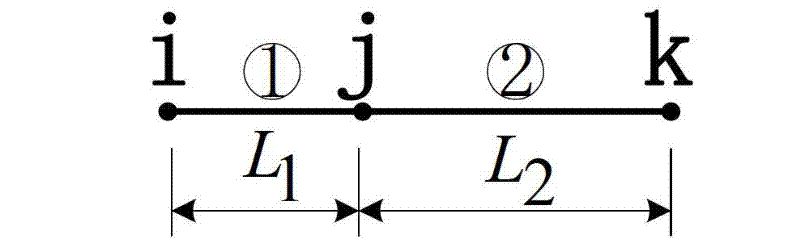

Method used

Image

Examples

Embodiment 1

[0205] The ID number of the selected steel plate is 038682000, the steel type is Q550D, the thickness of the steel plate is 50mm; the cooling temperature is 780°C, and the water cooling time is 21S; chemical composition: C: 0.084%; Mn: 1.8%; Cr: 0.02%; Nb: 0.045%; V : 0.051%; Mo: 0.002%; Ni: 0.01%; Ti: 0.016%; Cu: 0.01%; water temperature 24°C; density: 7800kg / m3. Specific heat: obtained from Table 1 according to its chemical composition; thermal conductivity: obtained from Table 2 according to its chemical composition; the water-cooling heat transfer coefficient is taken as the comprehensive water-cooling heat transfer coefficient of the water-cooling process 4000W / (m 2 ·K); time step Δτ=3S; the thickness of the steel plate is divided into 20 finite elements and 21 nodes at equal intervals;

[0206] Table 1 Specific heat table (kJ / kg K)

[0207]

[0208] Table 2 Thermal conductivity table (W / m K)

[0209]

[0210] Based on the above simulation conditions, the temperat...

Embodiment 2

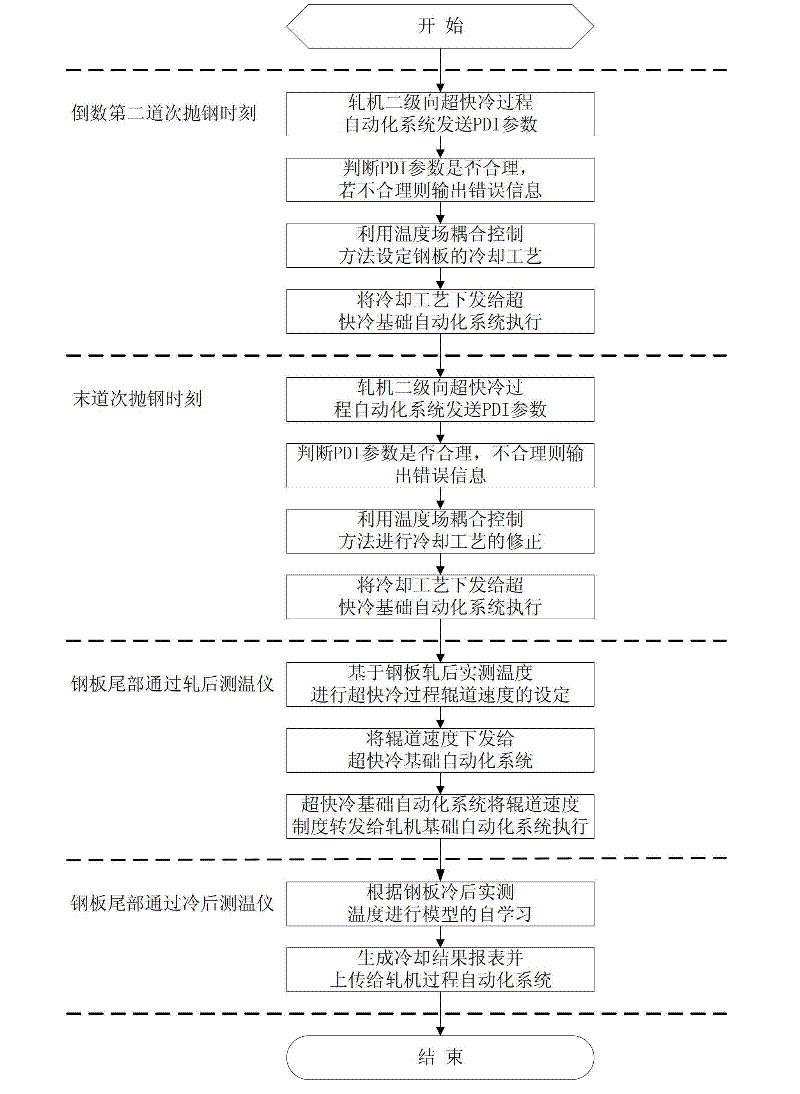

[0215] The control system used in the control method of this embodiment includes the ultra-fast cooling basic automation system, the ultra-fast cooling process automation system, the ultra-fast cooling equipment, the side spray device and the detection instrument. The system structure diagram is as follows Figure 8 shown.

[0216] In this embodiment, the ultra-fast cooling basic automation system adopts a set of Siemens S7-400PLC as the main control unit of the ultra-fast cooling equipment, communicates with the remote I / O module through the Profibus DP network, and the remote I / O module is directly connected to the field instrument through a cable Its hardware includes: one UR1 rack, one power supply PS 40720A, one central processing unit CPU 416-2DP, one communication module CP 443-1, two counter modules FM 451FIX SPEED, and AI, AO modules, DI, DO modules Several; its application software: adopt SIMATIC STEP7 application software.

[0217] The ultra-fast cooling process au...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com