Middle and low temperature control device of simulated moving bed chromatograph

A technology for simulating moving bed and temperature control device, which is applied in the direction of temperature control, measuring device, and material separation by using electric methods, which can solve the problems of no better solution, complicated design, difficult operation, etc., and solve the problem of temperature balance , Improve production efficiency and consume less energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

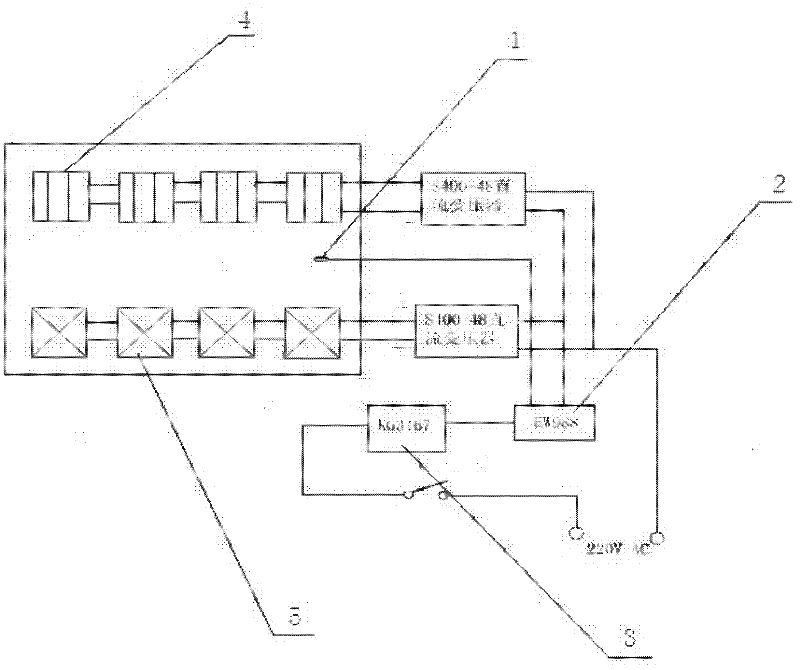

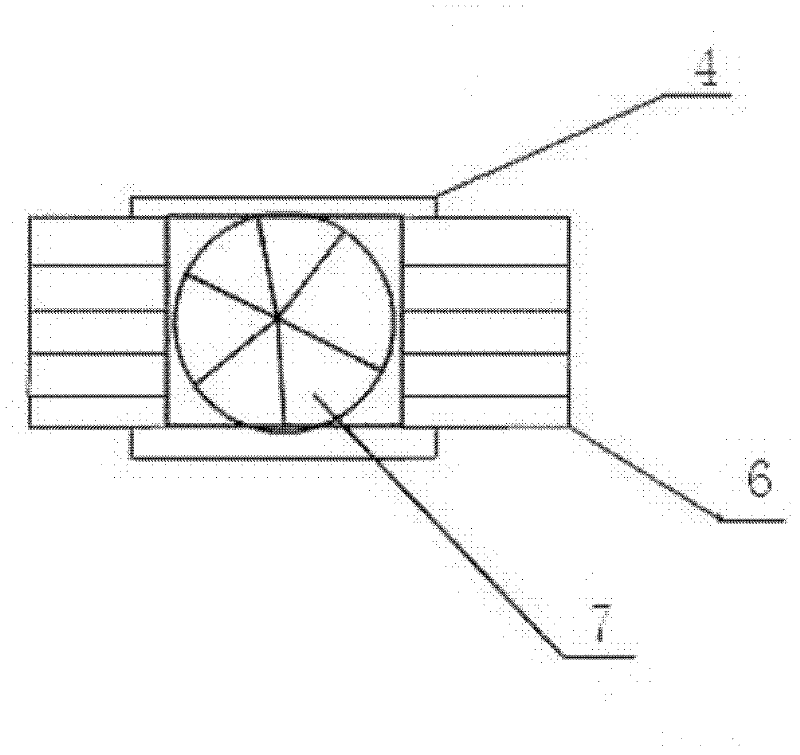

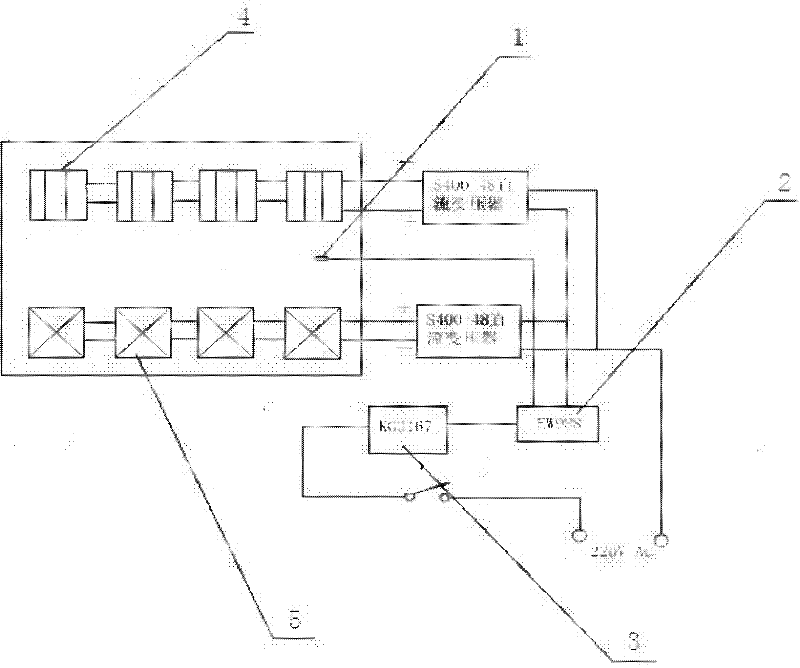

[0017] Such as figure 1 and figure 2 As shown, the medium and low temperature temperature control device of the simulated moving bed chromatography is composed of a temperature control box, a temperature adjustment component, a temperature sensor 1, a temperature controller 2, a temperature reservation setting module 3 and a power supply system. Wherein the temperature regulating part is composed of a semiconductor heating sheet 4, a semiconductor cooling sheet 5, an aluminum alloy heat sink 6 and a fan 7. The semiconductor heating sheet 4 is installed inside the temperature control box, and the installation method is in series, and the heat sink is installed on the surface of each semiconductor heating sheet and semiconductor cooling sheet. The temperature controller is installed inside the temperature control box, and the temperature controller is connected to the temperature sensor, the semiconductor heating sheet and the semiconductor cooling sheet through wires to reali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com