Process for treating oily wastewater in metallurgical industry and device thereof

A wastewater treatment and metallurgical industry technology, applied in the direction of filtration separation, gravity filter, loose filter material filter, etc., can solve the problems of blocking cooling nozzles, reducing service life, affecting process reuse, etc., to achieve the effect of increasing the number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

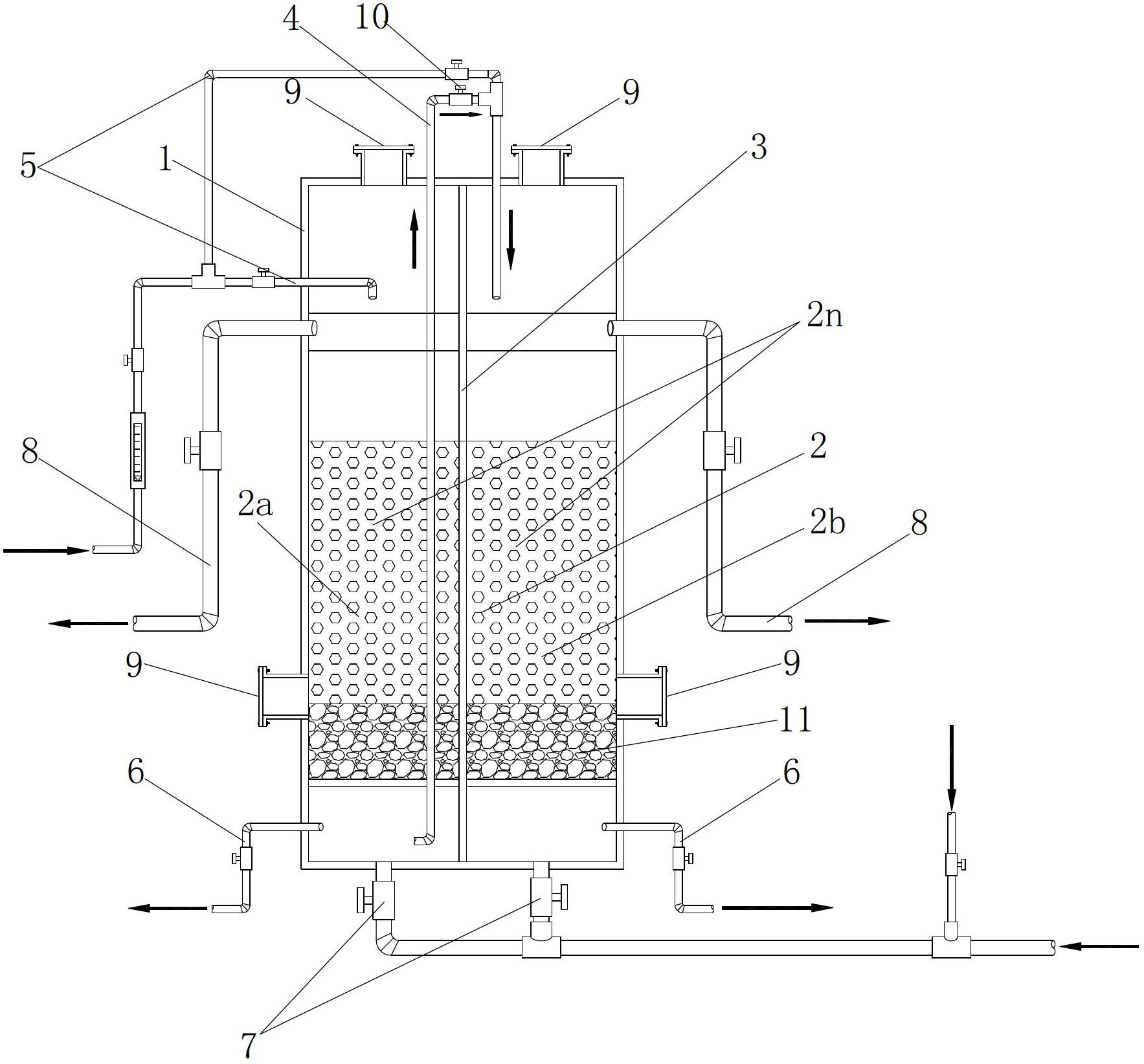

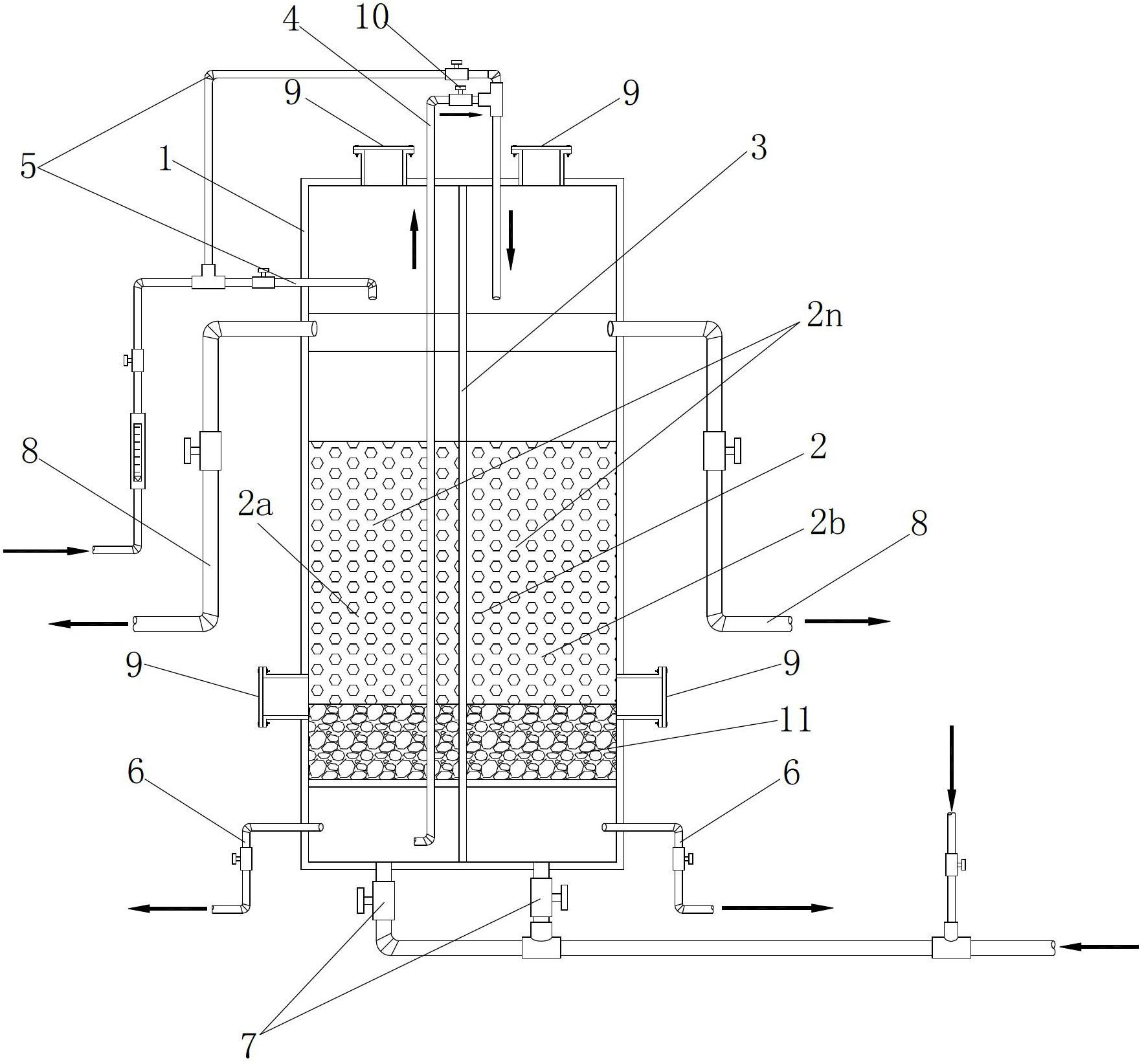

[0029] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0030] A process for treating oily wastewater in the metallurgical industry, the process comprises the following steps:

[0031] 1) In a relatively closed tank 1, the primary filter grid 2a and the secondary filter grid 2b are arranged side by side. The filter material used in the primary filter grid 2a and the secondary filter grid 2b is a porous filter based on waste sludge from the metallurgical industry. The filter material is composed of 30-50% metallurgical comprehensive sludge, 18-30% coal gangue, 8-20% metallurgical power plant fly ash, and 10-40% coal powder by weight percentage. become;

[0032] 2) Transport the oily wastewater to the top of the primary filter grid 2a, use the pressure in the tank 1 to make the oily wastewater pass through the primary filter grid 2a, and filter out from the bottom of the primary filter grid 2a to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com