Catalyst for synthesizing ethylene amine and method for preparing ethylene amine

A catalyst and ethylene amine technology, applied in the field of catalysts for synthesizing ethylene amine, can solve the problems of high energy consumption, serious equipment corrosion and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

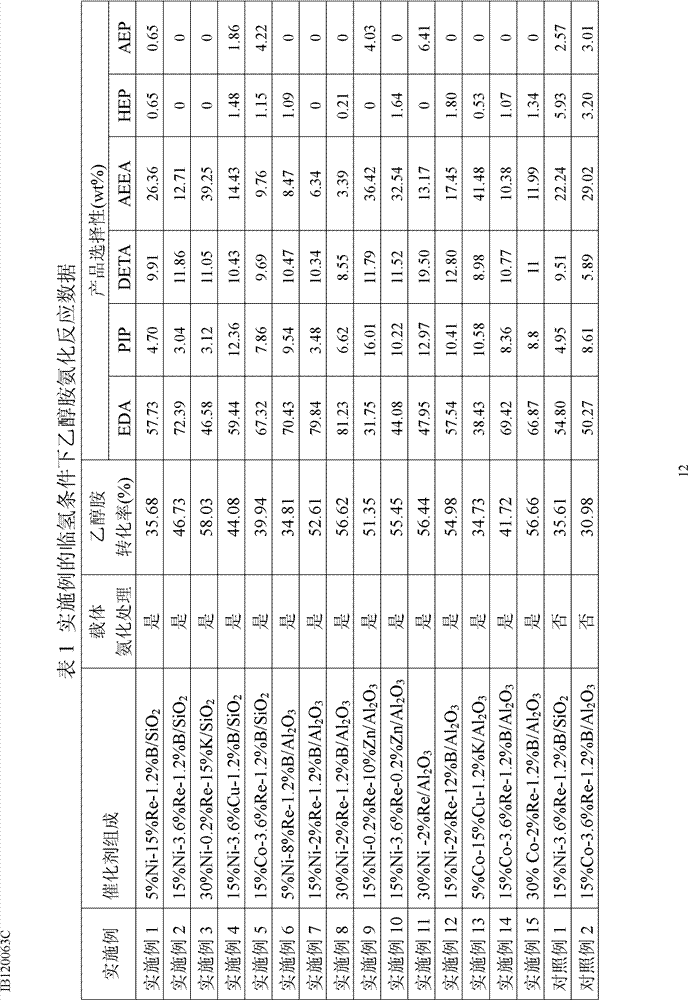

Examples

Embodiment 1

[0033] 5%Ni-15%Re-1.2%B / SiO 2 Catalyst preparation and application

[0034] Weigh 10 g carrier SiO 2 (20-40 mesh), the carrier SiO 2 Install in a quartz tube, dry at 200°C for 5 hours under an inert atmosphere, then introduce 10% ammonia-hydrogen gas mixture (molar content), ammoniation temperature is 300°C, and ammoniation time is 5 hours. 2.477 g Ni(NO 3 ) 2 ·6H 2 O, 2.161 g NH 4 ReO 4 and 0.686 g H 3 BO 3 Dissolve in 12ml deionized water. Half of this aqueous solution was used to impregnate the above ammoniated SiO 2 The carrier was air-dried, then dried at 120°C for 4 hours, and then calcined at 500°C for 4 hours. Then, impregnate the ammonified SiO 2 The carrier is then air-dried, dried at 120°C for 4 hours, and calcined at 500°C for 4 hours. Before the catalyst is used, in a hydrogen flow at 375°C (atmospheric pressure, 2000h -1 ) to reduce for 4 hours. When the temperature in the reactor is naturally lowered to 160°C, the pressure is increased to 8MPa. Af...

Embodiment 2

[0036] 15%Ni-3.6%Re-1.2%B / SiO 2 Catalyst preparation and application

[0037] Weigh 10 g carrier SiO 2 (20-40 mesh), the carrier SiO 2 Install in a quartz tube, dry at 200°C for 5 hours under an inert atmosphere, then introduce 20% ammonia-hydrogen gas mixture (molar content), ammoniation temperature is 300°C, and ammoniation time is 5 hours. 7.432 g Ni(NO 3 ) 2 ·6H 2 O, 0.518 g NH 4 ReO 4 and 0.686 g H 3 BO 3 Dissolve in 12ml deionized water. Refer to Example 1 for the remaining preparation steps and catalyst evaluation scheme. The reaction results are shown in Table 1.

Embodiment 3

[0039] 30%Ni-0.2%Re-15%K / SiO 2 Catalyst preparation and application

[0040] Weigh 10 g carrier SiO 2 (20-40 mesh), the carrier SiO 2 Install in a quartz tube, dry at 200°C for 5 hours under an inert atmosphere, then introduce 50% ammonia-hydrogen gas mixture (molar content), ammoniation temperature is 300°C, and ammoniation time is 5 hours. 14.864 g Ni(NO 3 ) 2 ·6H 2 O, 0.029 g NH 4 ReO 4 and 3.879 grams of KNO 3 Dissolve in 12ml deionized water. Refer to Example 1 for the remaining preparation steps and catalyst evaluation scheme. The reaction results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com