Water-cooling type impact flour milling machine

An impact mill and water-cooled technology, which is applied in the field of impact mill, can solve the problems of poor output of steamed bread flour, decreased edible quality, high temperature rise, etc., and achieves improved quality, improved edible quality of finished products, and reduced noise. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

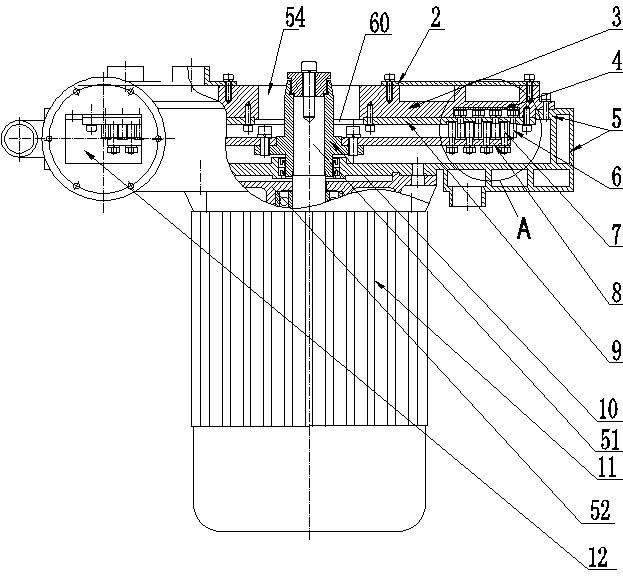

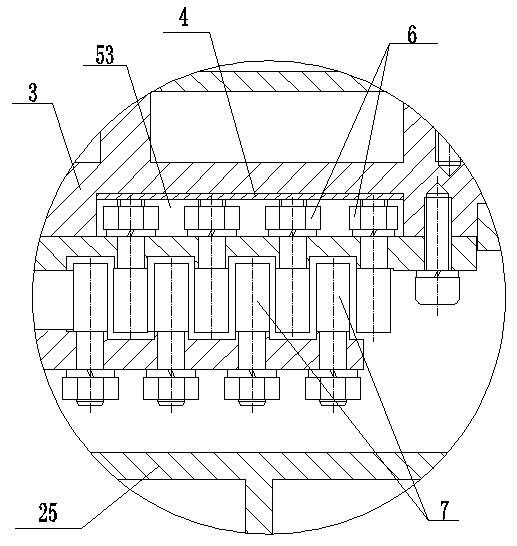

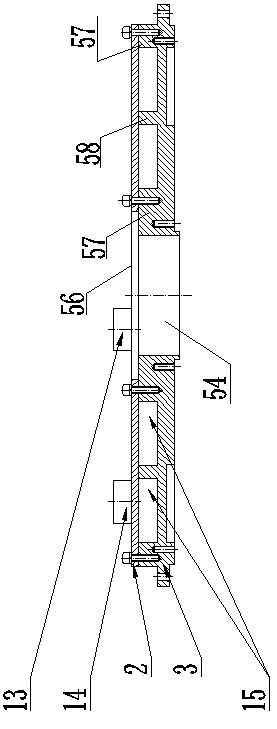

[0025] Such as Figure 1 to Figure 6 As shown, the water-cooled impact mill of the present invention includes a motor 11, and the motor shaft 51 is fixedly connected with a disc-shaped rotor disc 8 through a hub 10, and at least three turns of rotor pins 7 are installed on the rotor disc 8, and the rotor pins The cross-section of 7 is a square, and the number of rotor pins 7 is the same as that of the existing impact mill, at least dozens. The hub 10, the rotor disk 8 and the rotor pin 7 form a rotor component.

[0026] Such as figure 1 , Figure 5 and Figure 6 As shown, the housing of the motor 11 is provided with a flange 52, and the motor flange 52 is fixedly connected with the organic casing 5. The casing 5 is a steel plate weldment, including a casing bottom plate 25, a casing panel 26 and a The volute 18 between the casing bottom plate 25 and the casing panel 26; the casing cover plate 3 is installed on the upper surface of the casing 5, and the bottom of the casing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com