Six-axis industrial robot control system with PLC (programmable logic control) function

A technology of industrial robots and control systems, which is applied in the direction of program-controlled manipulators, manipulators, manufacturing tools, etc., can solve the problems of high cost and large volume of the main controller, and achieve the effects of novel overall structure, concise language, and convenient operation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

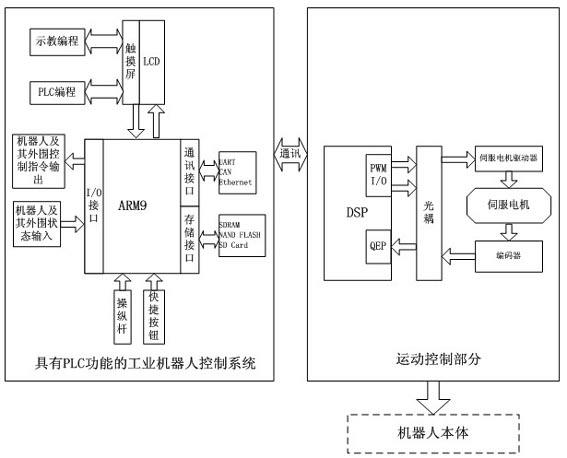

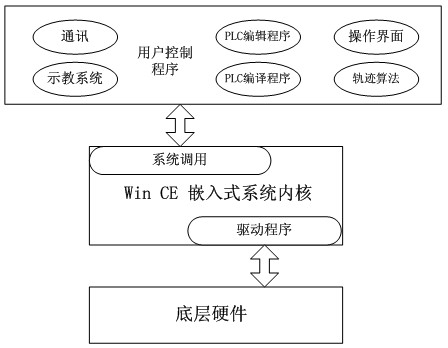

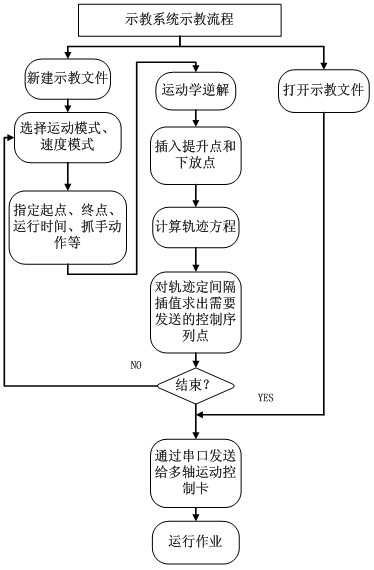

[0012] like Figure 1~2 Architecture diagram and software architecture diagram of a six-axis industrial robot control system with PLC function, the system includes: ARM9 microprocessor, memory module, communication module, LCD and touch screen display module, I / O interface module, joystick module, shortcut button It consists of hardware part and software part consisting of WINCE embedded system kernel, hardware-based driver and user program.

[0013] The industrial robot control system takes the ARM9 processing chip as the core. As the main control chip of the control system, ARM9 is responsible for the control of the entire system, human-computer interaction, multi-machine communication, trajectory algorithm, teaching control, PLC control, etc., and various algorithms can be used to improve the performance of the control motor.

[0014] The touch display screen of the robot control system is the input and output device for the robot control. It can not only realize the input...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com