Preparation method of nanoparticle-reinforced Al-Fe-Cr-Ti-Re heat-resistant aluminum alloy sheet

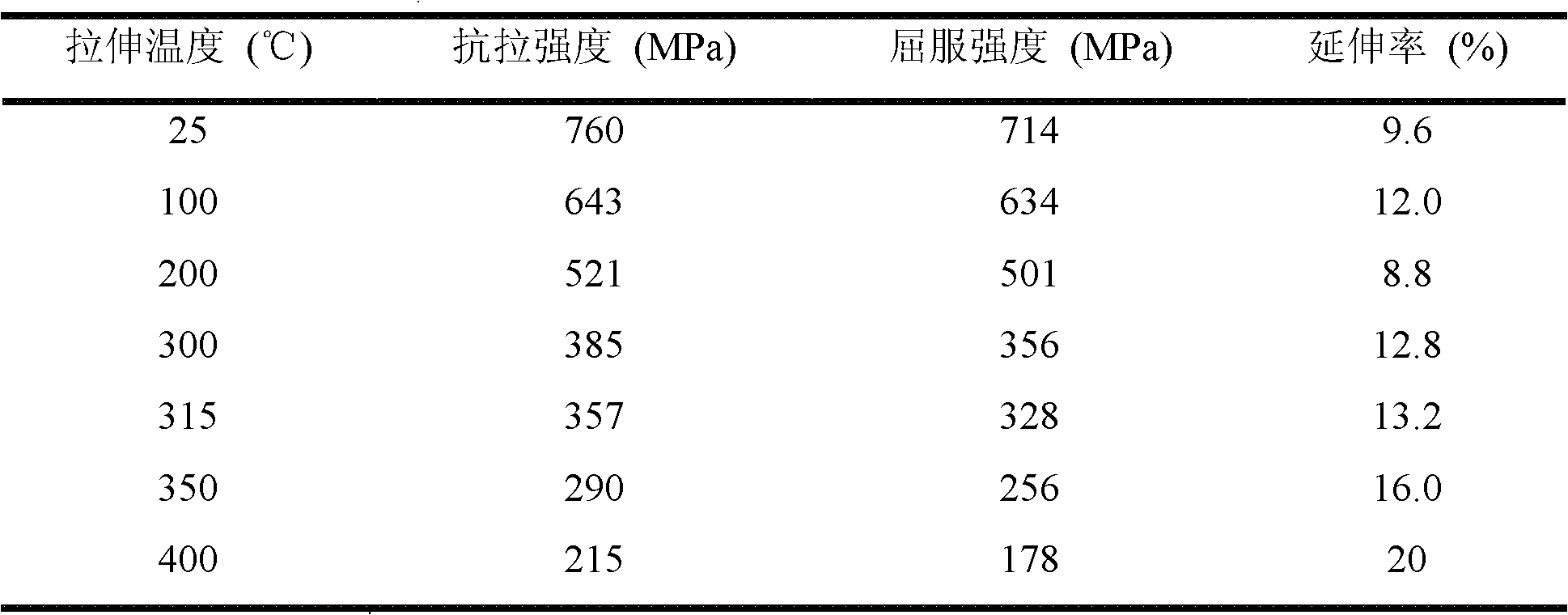

An aluminum alloy sheet and nanoparticle technology, which is applied in the field of preparation of aluminum alloy sheets, can solve the problems of complex densification and forming of large-size aluminum alloy sheets, poor mechanical properties at room temperature and high temperature, and high cost, so as to improve equipment utilization, Outstanding high temperature mechanical properties and the effect of improving density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0010] Specific implementation mode 1: This implementation mode is a method for preparing a nanoparticle-reinforced Al-Fe-Cr-Ti-Re heat-resistant aluminum alloy plate, which is specifically completed according to the following steps:

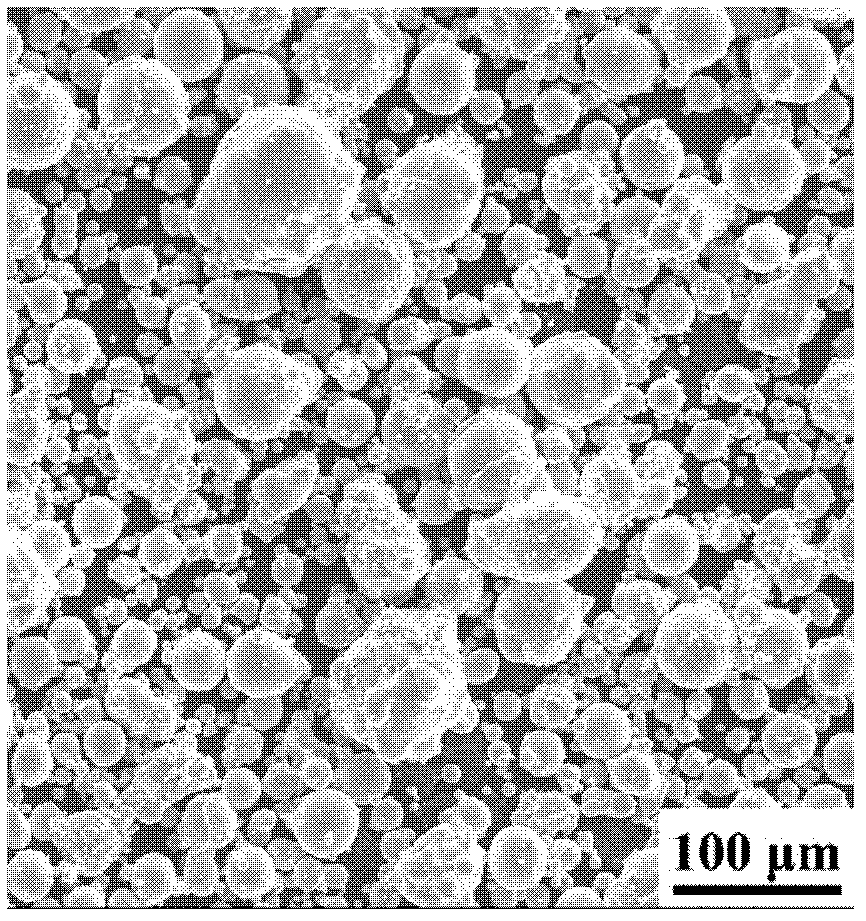

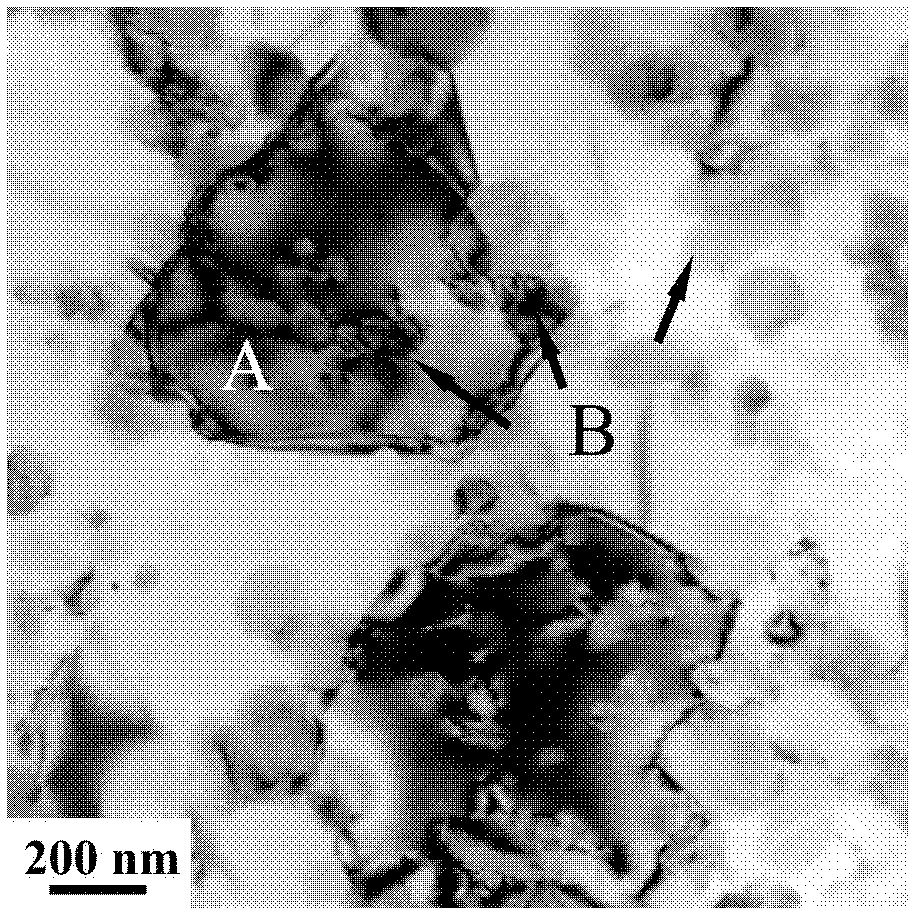

[0011] 1. Preparation of alloy powder by gas atomization: first prepare 5%-6.5% Fe, 3.1%-4.1% Cr, 2.8%-3.8% Ti, 0.01-2% Re and Al as the balance according to the mass percentage, and then prepare the The percentage preparation is 5%~6.5%Fe, 3.1%~4.1%Cr, 2.8%~3.8%Ti, 0.01~2%Re and the balance is Al mixed in sequence, after refining and degassing, pour the melt into the gas atomization system In the powder equipment, the proportioning material is prepared into spherical alloy powder with a particle size of less than 100 μm by gas atomization method to obtain Al-Fe-Cr-Ti-Re alloy powder; 2. Cold isostatic pressing: firstly, in the rubber bag Coat a layer of zinc stearate inside the sleeve, then put the Al-Fe-Cr-Ti-Re alloy powder into the rubber sh...

specific Embodiment approach 2

[0019] Specific embodiment two: the difference between this embodiment and specific embodiment one is: in step two, first coat a layer of zinc stearate in the rubber sheath, then put Al-Fe-Cr-Ti-Re alloy powder into Put it in the rubber sheath, and seal it after shaking, then put it in the cavity of the cold isostatic press, and then start to inject liquid pressure medium into the cavity of the cold isostatic press until it is full, and then increase the pressure to 240MP ~ 320MPa, and Cold isostatic pressing is performed for 300s to 500s under a pressure of 240MP to 320MPa to obtain a cold isostatic blank. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0020] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the liquid pressure medium described in step 2 is anti-wear hydraulic oil, emulsion or transformer oil. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com