Abrasive articles including abrasive particles bonded to an elongated body, and methods of forming thereof

一种长形本体、磨料颗粒的技术,应用在磨料、磨削装置、薄料处理等方向,能够解决磨料丢失、树脂线锯的粘结易于快速地磨损等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

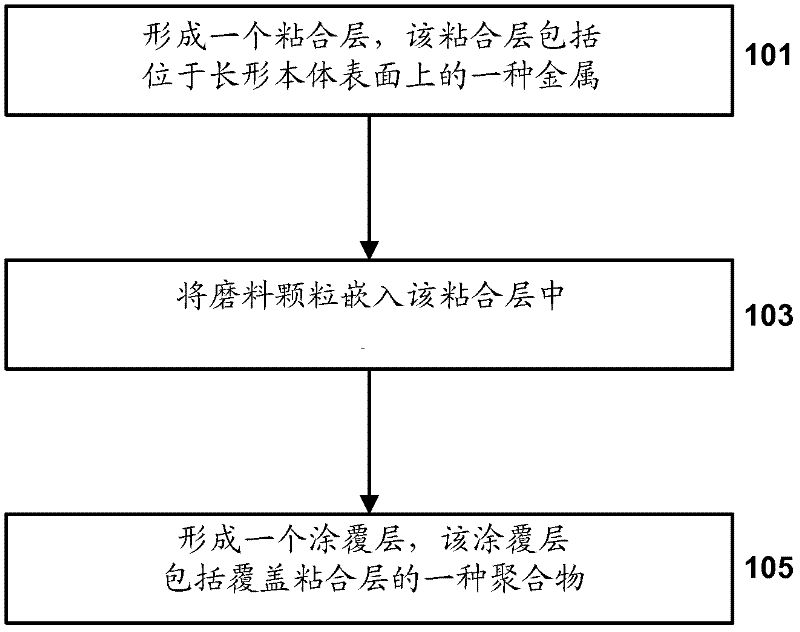

Method used

Image

Examples

example

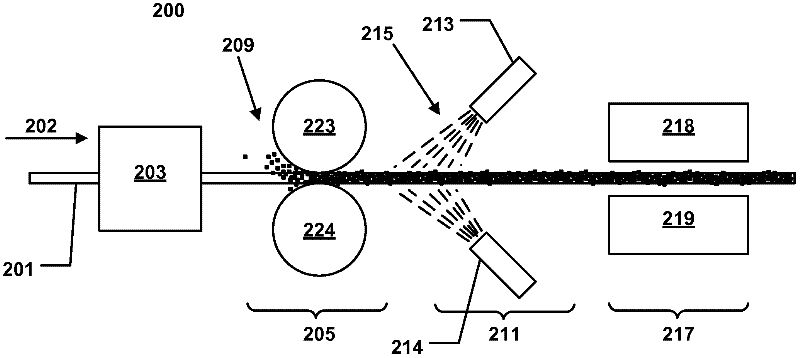

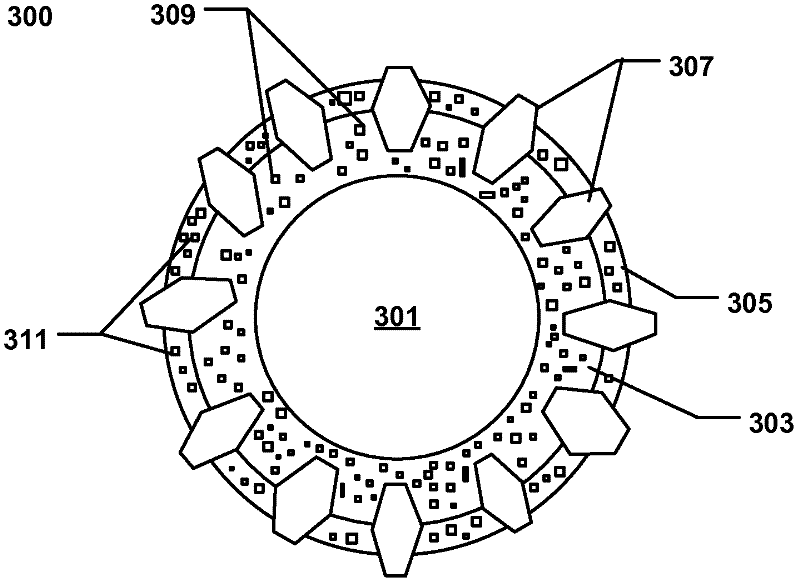

[0071] An exemplary abrasive article formed according to the processes herein is described below. A steel wire core of high strength steel wire having an average diameter of approximately 150 microns is obtained. The steel wire was coated with a copper bonding layer using electroplating such that the bonding layer had an average thickness of approximately 20 microns. It is worth noting that, for this example, it was determined that 20 microns was sufficient in view of the size of the abrasive grains to be used.

[0072] After electroplating the bonding layer to the steel wire core, the steel wire is passed through rollers with abrasive particles attached to the surface of the rollers to help embed the abrasive particles in the bonding layer. Abrasive particles of diamond having an average diameter of 25 microns were selected and embedded in the copper bond layer to an average depth of approximately 10 to 15 microns.

[0073] The diamond-embedded wire was then passed through ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com