Reduction treatment method for ballast water

A treatment method and ballast water technology, applied in the direction of reduction water/sewage treatment, water/sewage treatment, natural water treatment, etc., to achieve the effect of simple reduction treatment and low environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

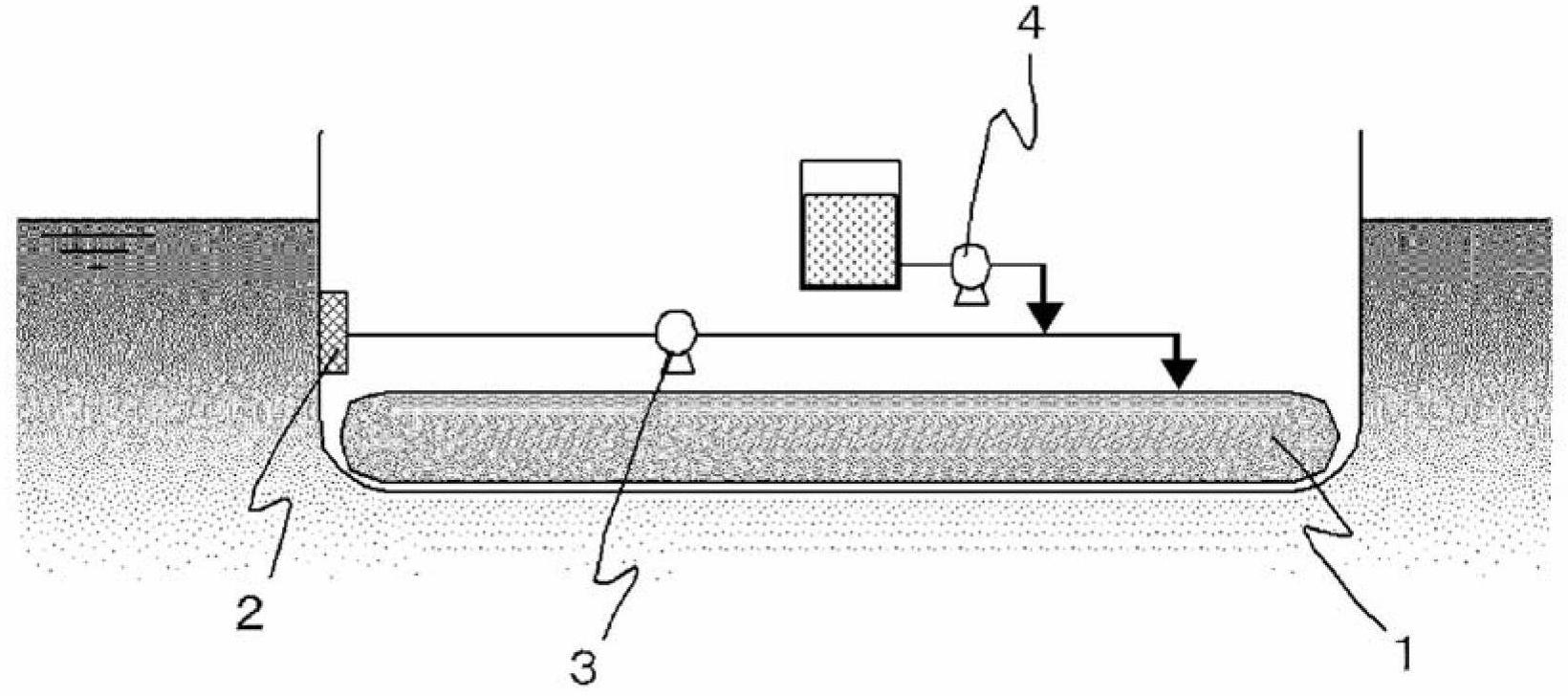

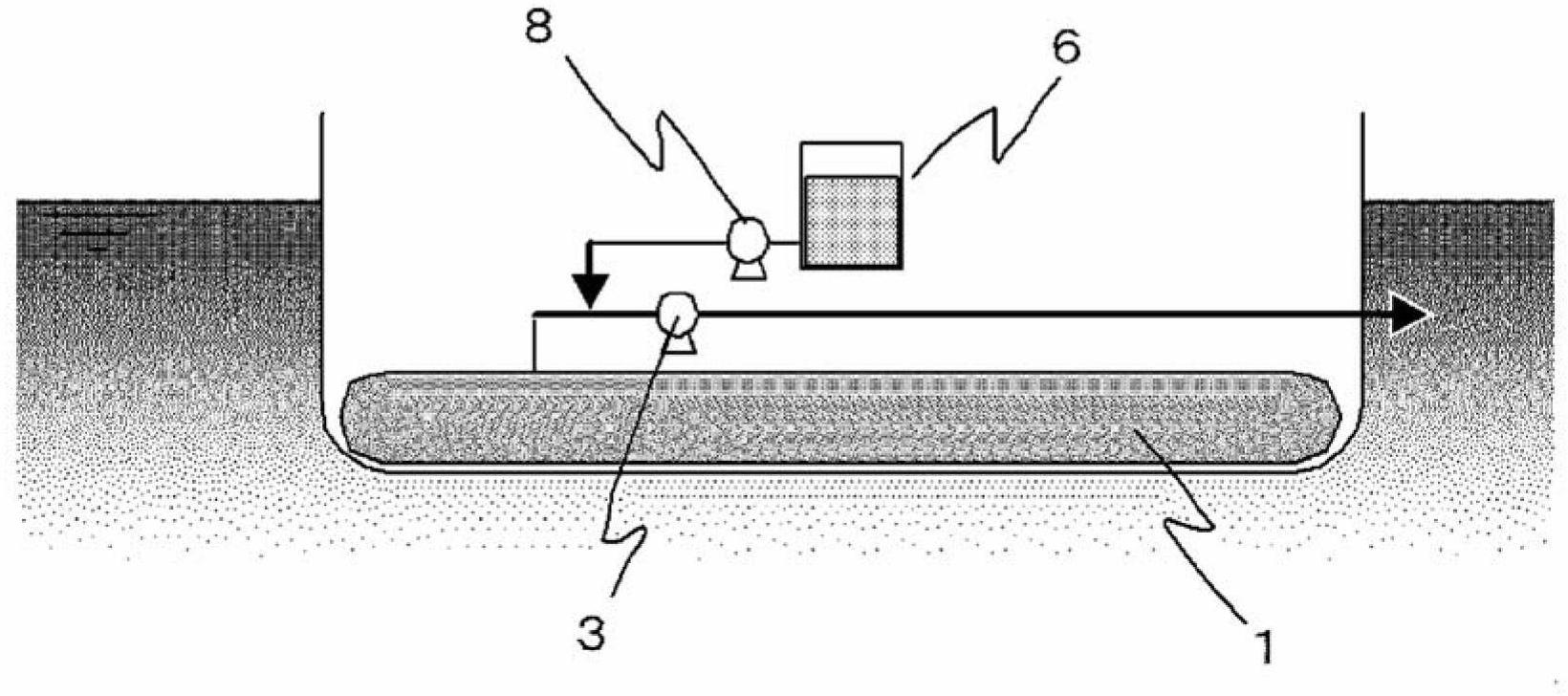

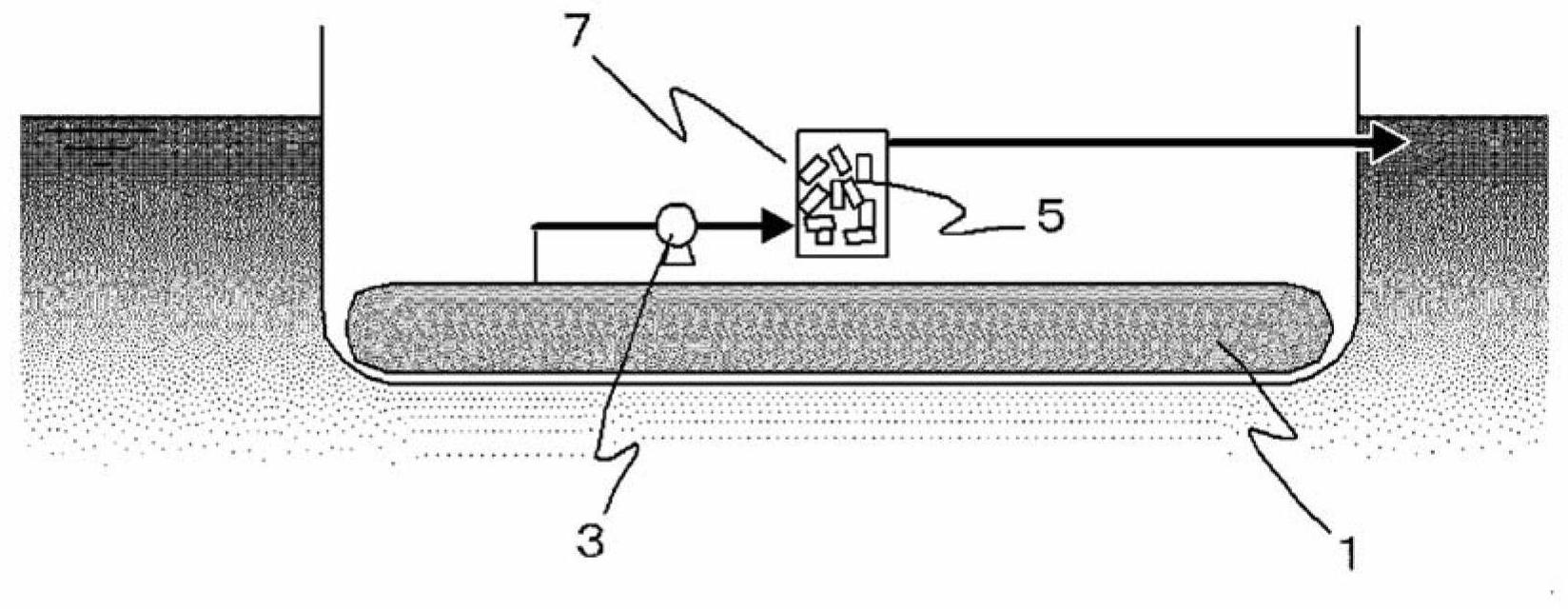

Method used

Image

Examples

Embodiment 1

[0063] 60 parts by weight of anhydrous sodium sulfite white powder and 40 parts by weight of sodium chloride were put into a container-fixed mixer, stirred with a paddle, and fully mixed. The mixture was compressed with a granulator at a compression pressure of 25 MPa to obtain cylindrical pellets with a diameter of 50 mm and a length of 30 mm. The breaking strength is 960N.

Embodiment 2

[0067] Prepare respectively the mixture A containing 100 parts by weight of anhydrous sodium sulfite white powder, the mixture B containing 90 parts by weight of sodium sulfite white powder and 10 parts by weight of sodium chloride, the mixture C containing 80 parts by weight of sodium sulfite white powder and 20 parts by weight of sodium chloride , mixture D containing 70 parts by weight of sodium sulfite white powder and 30 parts by weight of sodium chloride, mixture E containing 60 parts by weight of sodium sulfite white powder and 40 parts by weight of sodium chloride, containing 50 parts by weight of sodium sulfite white powder and 50 parts by weight of chloride Sodium mixture F. The mixtures A to F were compressed with a granulator at a compression pressure of 25 MPa to obtain a cylindrical solid with a diameter of 50 mm and a length of 30 mm. Table 1 shows the results of observing the tableting state of the obtained solid.

[0068] Table 1

[0069]

Mixtur...

Embodiment 3

[0073] 50 parts by weight of anhydrous sodium sulfite white powder and 50 parts by weight of sodium chloride were charged into a container-fixed mixer, stirred with a paddle, and mixed thoroughly. This mixture was tabletted with a granulator (manufactured by Mashina Corporation) at a tableting pressure of 4 MPa, 5 MPa, 25 MPa, and 30 MPa to obtain cylindrical pellets a to d with a diameter of 50 mm and a length of 30 mm. Here, the tablet compression pressure refers to the gauge pressure of the hydraulic pressure of the tablet compression machine. Table 2 shows the results of measuring the breaking strength (N) of the obtained pellets a to d using SJ-50 (manufactured by Maruhishi Scientific Machinery). It should be noted that the breaking strength (N) indicates the maximum force when the tablet is sandwiched by a flat plate and compressed to break it. in addition, Figure 4 Indicates the relationship between tableting pressure and breaking strength.

[0074] It should be not...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com