Candy containing silkworm protein and preparation process of candy

A technology for silkworm chrysalis protein and preparation process, which is applied in the confectionery industry, confectionery, food science and other directions, can solve the problems of subsequent processing difficulties, removal, safety doubts, etc., and achieves good deodorization effect, high sensory evaluation, and rich nutrition. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

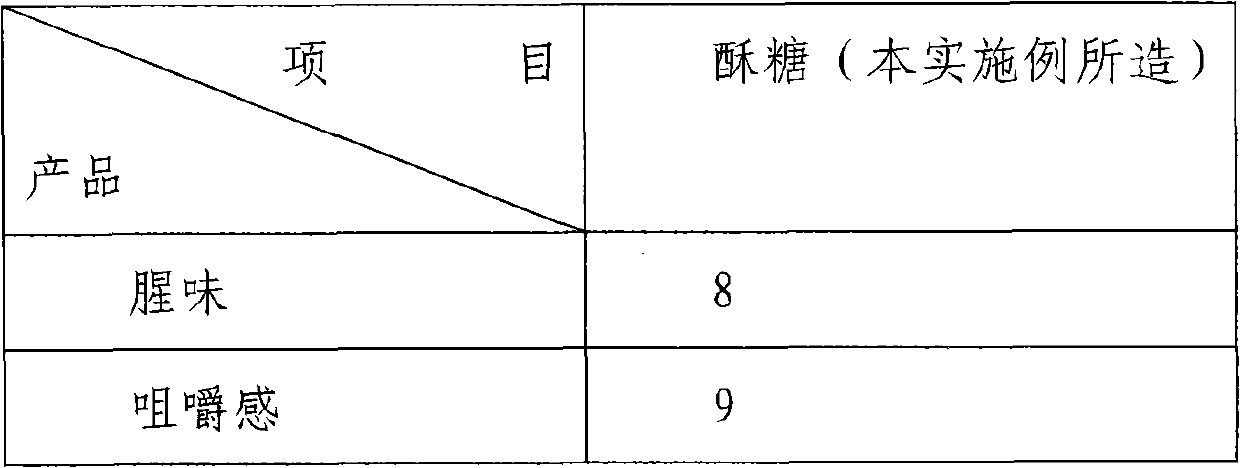

Examples

Embodiment 1

[0021] (1) Select silkworm chrysalis → wash → freeze and peel → thaw and remove internal organs → soak in 70°C water for 20 minutes → change to cold water for 60 minutes → change water 3 times in a row → remove → beating → add β at a ratio of 1:2 - Cyclodextrin and maltodextrin (both account for 6% of silkworm chrysalis weight) → 60 ° C for 30 minutes → vacuum microwave drying → pulverization → standby.

[0022] (2) According to the ratio of silkworm chrysalis to 30% by weight in the stuffing, add white sugar powder, cooked sesame powder, peanut powder → mix → add honey or margarine → make the stuffing, roast on low heat until soft.

[0023] (3) Boil the white sugar in a pot to 160°C → melt it and place it upside down on the chopping board → pull and fold it until it turns white → flatten it → cut it into pieces → bury it in the hot stuffing to soften → take it out and press it → make a sugar skin .

[0024] (4) Put the sugar filling on the sugar skin, fold and flatten repeat...

Embodiment 2

[0043] Pretreatment of silkworm chrysalis: selection of silkworm chrysalis → washing → freezing and peeling → thawing to remove internal organs;

[0044] Silkworm chrysalis deodorization treatment: Soak in 55°C water for 35 minutes → change to cold water for 45 minutes → change the water continuously 4 times → remove → beat pulp → add β-cyclodextrin and maltodextrin in a ratio of 1:2 (both Accounting for 3% of the weight of silkworm chrysalis) → 45°C for 25 minutes;

[0045] Pretreatment of adding sugar: drying→crushing→reserve;

[0046] ●Sugar input treatment: add sugar raw materials to make candy.

[0047] Preferably, the drying in the step of sugar pretreatment is vacuum microwave drying.

[0048] Preferably, the step of adding sugar includes the following steps: according to the proportion of silkworm chrysalis in the stuffing to 20% by weight, add white sugar powder, cooked sesame powder, peanut powder → mix → add honey or margarine → make the filling Roast the ingredi...

Embodiment 3

[0051] Contains the following steps:

[0052] Pretreatment of silkworm chrysalis: selection of silkworm chrysalis → washing → freezing and peeling → thawing to remove internal organs;

[0053] Silkworm chrysalis deodorization treatment: soak in 70°C water for 20 minutes → change to cold water for 60 minutes → change the water 3 times → remove → beat pulp → add β-cyclodextrin and maltodextrin in a ratio of 1:2 (both Accounting for 4% of the weight of silkworm chrysalis)→50°C for 30 minutes;

[0054] Pretreatment of adding sugar: drying→crushing→reserve;

[0055] ●Sugar input treatment: add sugar raw materials to make candy.

[0056] Preferably, the drying in the step of sugar pretreatment is vacuum microwave drying.

[0057] Preferably, the step of adding sugar includes the following steps: according to the proportion of silkworm chrysalis in the stuffing that accounts for 40% by weight, add white sugar powder, cooked sesame powder, peanut powder → mix → add honey or margari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com